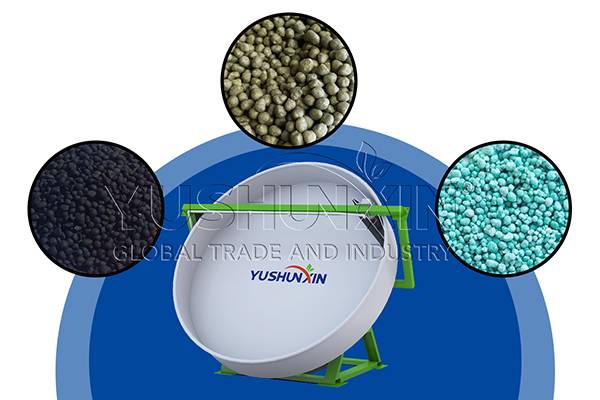

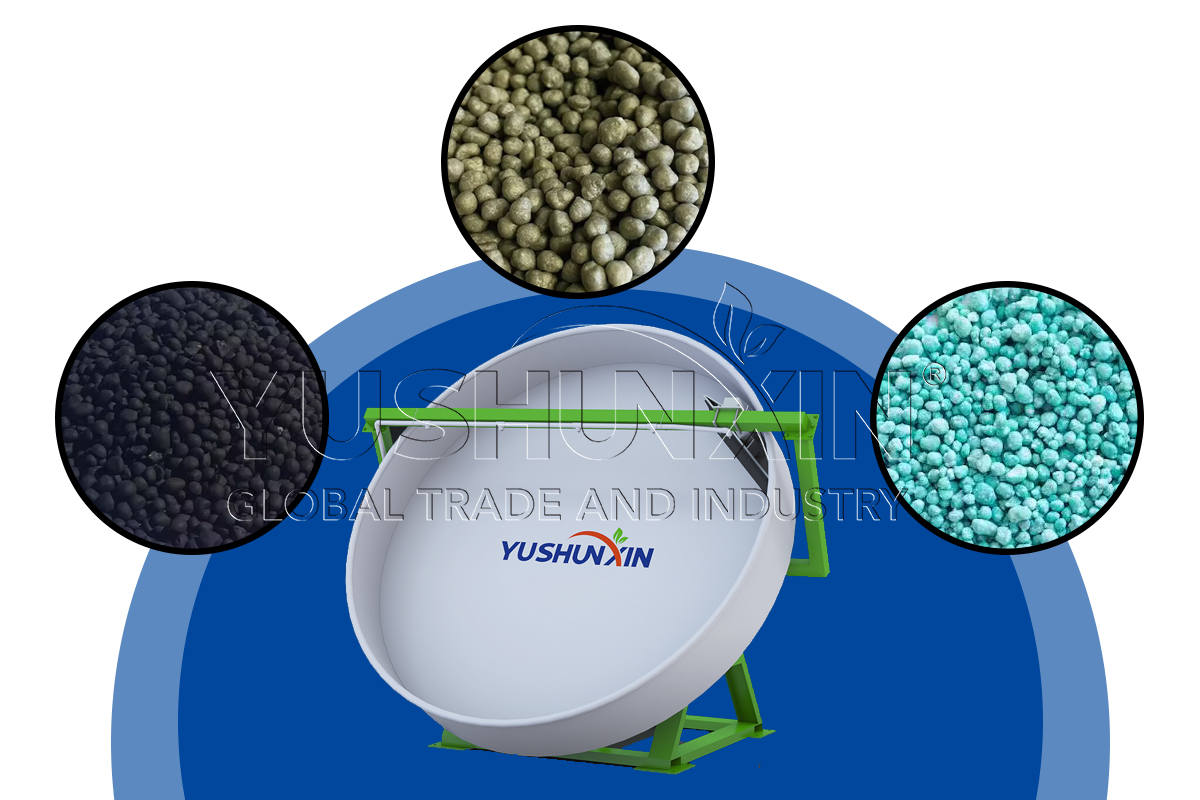

Disc granulator

- Power: 0,55 – 18,5 kW

- The size of the particles: 1 – 8 mm

- The degree of granulation: 93% +

- Production capacity: 0,02 – 6 subject.

- The size of the particles of raw materials before granulation: 50 oven.

- Moisture content of raw materials before granulation: 20% – 40%

- Equipment material: Carbon steel Q235, alloy alloy

- Application: Manure animals, The remains of biogas, humus, brown coal, NPK, bentonite, Mineral fertilizers…

Our disk granulator is a highly effective equipment for granulation. It is widely used in organic fertilizers, complex fertilizers, feed, building materials, chemical industry and other areas.

Our plate granulator is also known as a spherical granulator, steel plate granulator, Tarelly granulator, and he uses the process of wet granulation. It has a strong ability to granate and can process powder materials into homogeneous particles. Satisfy your production needs for various areas. Our disk granulators are from 1000 to 6000 dollars. Can satisfy your needs for various budgets. In this case, the diameter of the granulation disk ranges from 0,5 meter to 3,6 meter. Suitable for your production of any size. To purchase or get additional information, Please, Contact us.

How our plate granulator turns powder materials into granules?

Disk granulator is widely used equipment, used for converting powder materials into granules. The principle of its work mainly includes the following steps. First you need to place powder materials in a rotating disk granulator disk through Transportation system. A rotating disk drives the material in the disk under the influence of the engine drive. The material rolls and encounters under the influence of centrifugal force and gravity. As the disk continues to rotate, The particles of the material are gradually combined, Forming small particles. And gradually grow, absorbing more and more powdered materials and forming particles.

Contribute to the formation and stability of particles. In the process of granulation, it is usually necessary to spray water or glue, To regulate the moisture content of the material. By adjusting the angle of inclination, rotation speed and amount of liquid added to the disk. You can control the size and density of particles. When particles reach the required characteristics, They automatically roll from the edge of the disk. Then it is transmitted through the conveyor tape to the subsequent stages of processing, such as drying or sorting. This granulation method is easy to operate and has a uniform particle size. Therefore, it is widely chosen and used by many customers.

How much does it cost to buy a disk granulator at our factory?

PpOskolka we are a direct sales factory for fertilizer production, We offer you a very profitable price. We offer high -quality disk granulators of various models and sizes. He can satisfy the needs of the factory for the production of fertilizers of different sizes. The price range of one device is from 70 000 to 470 000 rubles. You can also get discounts when buying several devices. Since there are many models, You can contact us, to find out the cost of a disk granulator, which you want to buy. Regardless of your budget, We have a solution, corresponding to your specific needs. Make sure, that you will get the maximum return on your investment.

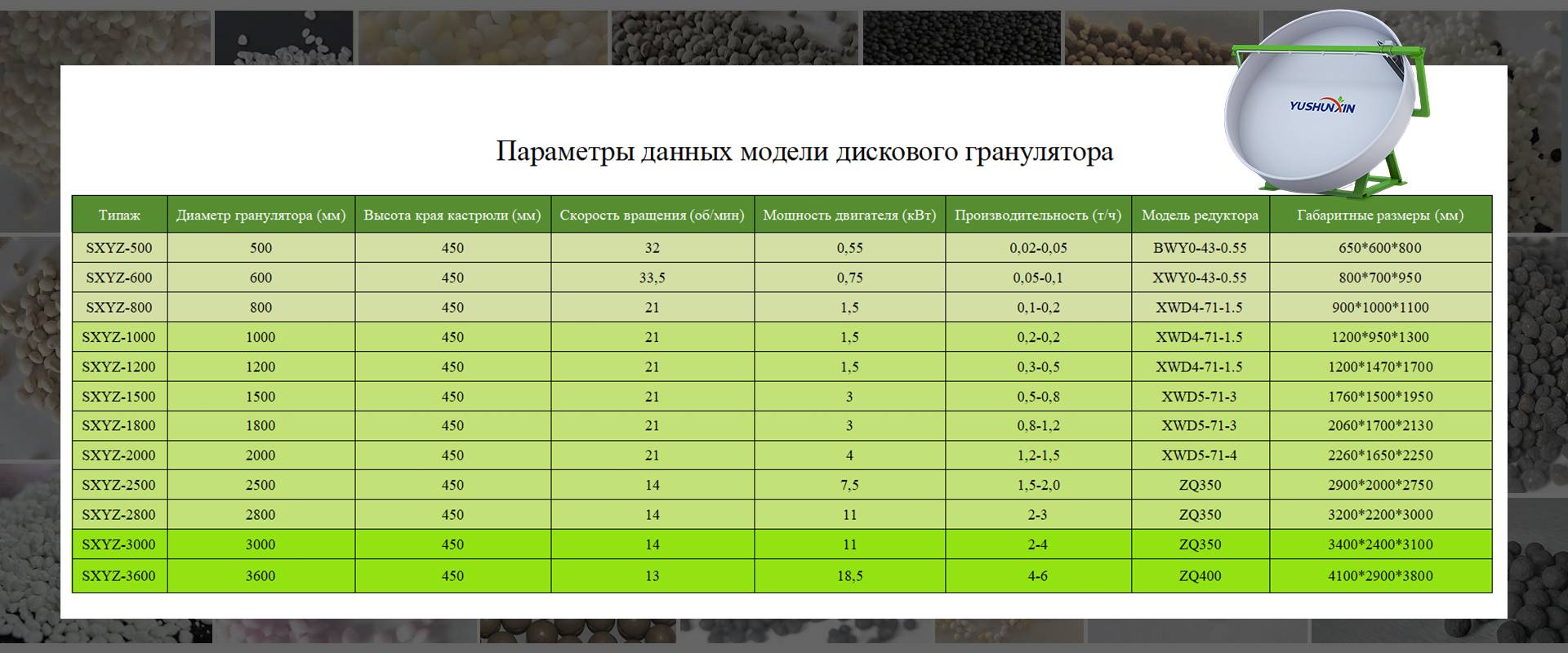

| Type | The diameter of the granulator (mm) | The height of the edge of the pan (mm) | Rotation speed (rpm) | Engine power (kW) | Performance (subject) | Reducer model | Dimensional dimensions (mm) |

|---|---|---|---|---|---|---|---|

| SXYZ-500 | 500 | 450 | 32 | 0,55 | 0,02-0,05 | BWY0-43-0.55 | 650*600*800 |

| SXYZ-600 | 600 | 450 | 33,5 | 0,75 | 0,05-0,1 | BWY0-43-0.55 | 800*700*950 |

| 800 | 800 | 450 | 21 | 1,5 | 0,1-0,2 | XWD4-71-1.5 | 900*1000*1100 |

| SXYZ-1000 | 1000 | 450 | 21 | 1,5 | 0,2-0,2 | XWD4-71-1.5 | 1200*950*1300 |

| SXYZ-1200 | 1200 | 450 | 21 | 1,5 | 0,3-0,5 | XWD4-71-1.5 | 1200*1470*1700 |

| SXYZ-1500 | 1500 | 450 | 21 | 3 | 0,5-0,8 | XWD5-71-3 | 1760*1500*1950 |

| SXYZ-1800 | 1800 | 450 | 21 | 3 | 0,8-1,2 | XWD5-71-3 | 2060*1700*2130 |

| SXYZ-2000 | 2000 | 450 | 21 | 4 | 1,2-1,5 | XWD5-71-4 | 2260*1650*2250 |

| SXYZ-2500 | 2500 | 450 | 14 | 7,5 | 1,5-2,0 | ZQ350 | 2900*2000*2750 |

| SXYZ-2800 | 2800 | 450 | 14 | 11 | 2-3 | ZQ350 | 3200*2200*3000 |

| SXYZ-3000 | 3000 | 450 | 14 | 11 | 2-4 | ZQ350 | 3400*2400*3100 |

| SXYZ-3600 | 3600 | 450 | 13 | 4-6 | ZQ350 | 4100*2900*3800 |

In what cases the purchase of a disc granulator will be more suitable for your production needs?

First of all, If the material, which needs to be granulated, has good adhesion and agglomeration. If you have it, The best choice will be a disk granulator. The disk granulator can effectively agglomerate these materials into homogeneous particles to satisfy production needs. If you have requirements for production of ready -made particles of uniform size and good appearance. You can buy a disk granulator. Provides a better form and consistency of particles.

Secondly, The disk granulator is especially suitable for the needs of small and medium production. If your production does not require particularly high performance, The use of a disk granulator can help you achieve production goals at a lower cost. If you have a limited budget, The disk granulator will be the perfect choice. Usually, It requires less initial investments and operational expenses. Simplicity of operation also makes it suitable for situations, when frequent adjustment of production parameters is required. Even if production needs are changed, You can adapt quickly.

Besides, The disk granulator occupies a small area and allows you to effectively save space. If your production room is limited in space, You can purchase a disk granulator. Suitable for the implementation of production activities in a limited space. When studying and developing new products, a disk granulator is the best granulation equipment for the stages of testing and developing new products. Because it can be quickly configured in accordance with various recipes and conditions of the technological process. This gives you the opportunity to experiment and make adjustments at the early stages of product development, to find the best production solution.

In which sectors our disk granulator is suitable for granular work?

Our discs can be used in a wide range of applications. Due to its effective work and wide applicability, He became the first choice equipment for many of our clients in the field of granulation. This granulator is excellent not only in the production of fertilizers. He also demonstrated excellent adaptability in many industries, such as the production of building materials, mining industry and metallurgy. Help clients to increase production efficiency and product quality.

Besides, Thanks to advanced technologies and stable work. The disk granulator is an ideal solution for the processing of resources and reducing environmental pollution in the environmental and chemical industry. For this reason, many customers, when choosing equipment for granulation, firmly choose our disk granulator. Our disk granulator can satisfy a variety of production needs and strict quality standards.

Examples of the use of a disk granulator

- 1

- 2

- 3

- 4

- 5

- 6

- 7

What are the advantages of acquiring and using our disk granulator for the production of granules of organic fertilizers?

Our plate granulator has an arched structure and three outputs, which significantly reduces labor capacity and increases labor efficiency. Besides, We also installed an automatic cleaning plate over the granulation disk, what saved your labor costs.

Besides, Our plane granulator can granulate at room temperature, ensure a single forming and achieve the degree of granulation of more 93%, what can reduce your investment costs and create good economic benefits for you. We have made a reasonable scheme, so that you can quickly start work.

How do we produce a high -quality plate granulator for you?

- For the lower part of the granulation disk of the disk granulator, we use the reinforcement process with a multi -rail steel plate. Besides, We also made a more severe and thick design of the base of the disk granulator, which allows you to smoothly move the disk granulator without the need to use anchor bolts.

- For the main transmission of the disc granulator, we use the process of high -frequency hardening. This can double the service life of the disco granulator you purchased.

- As for the lining of the disc granulator, We use high -strength fiberglass for you, which can reduce the loss of your equipment and reduce production costs.

- For a gearbox and a disk granulator engine, we use Flexible belt gear, which can reduce the force of impact and extend the service life of the disk granulator you purchased.

What size our plate granulator can produce high -quality organic granular fertilizers for you?

Our disk granulator can produce high -quality organic granular fertilizers the size of 1 to 8 mm. For high -quality granules size 1-4 mm our disk granulator can provide you with performance 90%.

· Particles <1 mm

Particles less in size 1 mm can be processed and continued to granulate. Our disk granulator can produce fertilizer granules for you in size less 1 mm and no more 3%.

· Particles >5 mm

For granular fertilizers in size 5 mm you can grind them through Chain crusher, and then re -enter into a disk granulate for granulation. Our disk granulator can produce a granular fertilizer for you in size 5 mm and no more 7%.

Can you control the size of the particles, produced by ours with a granulator?

Allowed. We can provide you with two methods, which will help you adjust the size of the particles.

In the first case, you can control the moisture content of raw materials or a system of spraying water of the disk granulator. The water content in the material is small, and the size of the granular fertilizer, produced by a disk granulator, Small. If the water content in the material is high, The size of the granular fertilizer, produced by a disk granulator, will be big.

The second method consists in monitoring the flat angle of inclination. The cooler the angle of the disk of the granulator of the disk granulator, the less granular fertilizer, it produces for you. The softer is the tilt of the granulator disk, the larger the granular fertilizer, which a disk granulator can produce for you.

How to set up an angle of inclination of a disk granulator?

Adjusting the inclination of the disk granulator is an important factor, affecting the output and quality of granules. Adjustment of the angle of inclination can change the time of stay of the material in the disk, thereby affecting the size and uniformity of particles. So how do you set it up? Before adjusting the tilt of the granulator disk, it is necessary to stop the machine and clean the surface of the disk. Determine the slope angle range (Usually 35 ° -55 °) Depending on the characteristics of the material. Find the adjustment, usually located at the bottom or side of the disk. It can be a screw, hydraulic cylinder or manually adjustable lever. Then loosen the bolts or nuts, fixing tilt. Use the adjustment device, to change the angle of disk, and confirm the angle using the corner line or scale. After installing in place, tighten the bolts or nuts.

After the setting is completed, you must check the stability of the device. Make sure, that the disk is securely fixed and does not talk. Then start the equipment, observe the effect of granulation and, if necessary, adjust the angle of inclination. Finally, write down the adjustment settings and regularly check them. We recommend that you make small, gradual adjustments. Do not make big changes at once. Different materials may require different angles of inclination, and you can flexibly regulate them in accordance with the characteristics of the material and the actual conditions. This adjustment method is a common method, used at our factory to adjust the disk granulator before sending customers. Hope, This will help you effectively adjust the angle of inclination of the disk granulator and improve the granulation effect.

What are the requirements for the moisture content of your raw materials, когда тарельчатый гранулятор гранулирует?

Our disk granulator requires, To make the moisture content in your raw materials below 30%. In the process of granulation of the disk granulator, the moisture content in your raw material will fall approximately to 20%. If you want, so that the humidity of the finished granular fertilizer is about 10%, We offer you Equip a dryer and use it with a disk granulator.

What to do, if the moisture content of your raw materials does not reach 30%, Don't worry, You can add a spray device to the disk granulator disk. He will work in a disk granulator to increase the humidity of the material to ensure your production needs.

What can you do, to extend the service life of a plane granulator?

When a disc granulator starts to work, You need to make sure, that there is no material in it. Moreover, Before starting, you need to apply yellow dry oil to the gear of a plane granulator. Before using the gearbox gearbox, the transmission oil must be added to the transmission oil once. And every four months you need to change the transmission oil.

Not only that, but both the chain and a sprocket of the plane granulator need to apply yellow dry oil once a week. Every three months, it is necessary to apply yellow dry oil to the seat of the bowl of a plate -granulator or even replace it with new yellow, dry oil.

Is it possible to configure our plate granulator in accordance with the needs of customers?

Certainly. After paying for the deposit, we will provide you with drawings of a disk granulator in accordance with your needs. You can continue to put forward your requirements after viewing the drawings of the disk granulator, And we will continue to modify them, Until you are satisfied. Finally, We will make your own disk granulator according to drawings.

What services can we provide you after, How you will purchase our plane granulator?

When your disk granulator will be ready, We will send you a video test machine. We suggest you send us your raw materials, And we will help you test the disk granulator. If you have a large amount of raw materials, You can also send us a payment. Let's buy your raw materials nearby, and then test the disk granulator. Of course, We also invite you to visit the test site of the disk granulator, And we are ready to accept you at any time.

Besides, We will also put into operation of the disc granulator At the factory, as well as installation services on the spot, To guarantee, that a disk granulator, which you will receive, It can work normally.

If you are interested in our plane granulator, Please, Contact us as soon as possible.

Seven basic problems, which are faced with the use of a disk granulator, and their solutions.

When using a disk granulator, you may encounter some common problems. Understanding these problems and their solutions can help you maintain the correct operation of your equipment and increase performance. Here are some common problems and the proposed solutions:

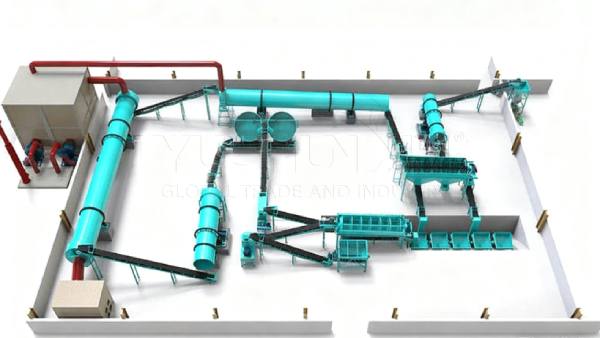

What equipment can be used with a disk granulator, To form a line for the production of disk granules for you?

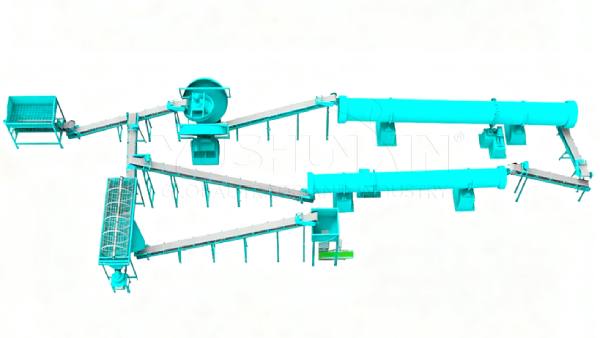

The line for the production of disk granules based on a disk granulator can be divided into two different production lines for the production of organic fertilizers and complex fertilizers. Each disk production line has its own workflow.

Line for the production of disk granulation of organic fertilizers Requires, so that you leave a place on the site for fermentation and composting raw materials. The raw materials are completely decomposed by professional equipment for fermentation and composting. The line for the production of disk granulation of complex fertilizers does not require this. Besides, Depending on the scale of production, the equipment also varies, used in the line of disk granules (on the example of the production of granules of complex fertilizers).

Small -scale disk particle line

Static dosing machine – disk mixer – disk granulator – Rotor dryer – Rotation cooler – Katka Zavodnaya machine – Packaging machine.

First, a static dispenser will perform accurate dosing. Then, through the conveyor tape, it is transmitted to disk mixer For thorough mixing. After the mixing is completed, the disk granulator will granate. The granules are then dried, Cool and sifted. Finally, packaging is carried out on automatic packaging weights.

Large -scale production line of disk granulation

Dose machine – Vertical crusher – Sifting car – Horizontal mixer – disk granulator – Drum granulator – Rotor dryer – Rotation cooler – Katka Zavodnaya machine – Rotor varnish machine – Packaging machine.

First of all, The dosing machine is controlled by a computer for an accurate dosage of raw materials. Then it Grinded with a vertical crusher to size, suitable for granulation. After sifting on a sifting machine, it is completely mixed with a horizontal mixer for uniform mixing. At the next stage, the disk granulator performs granulation, and then Drum granulator performs secondary granulation. After drying, cooling and sorting an additional process is carried out coating. Finally, Packaging is carried out.

Frequently asked questions about Balm -shaped granulator.

Disk granulator – This is widely used equipment in agricultural and industrial production, intended for granularity of powder or small materials. The following are some conventional applications disk granulator:

Fertilizer production: In the chemical industry, a disk granulator is used to turn bulk ingredients, Such as nitrogen, phosphorus, potassium, In granular forms, convenient for transportation and use.

Production of organic fertilizers: To turn organic materials, such as animal waste, Agricultural waste, city garbage, in granules of organic fertilizers.

Feed production: In the stern industry, disk granulators can mix various feed raw materials, and then granate it. Make the feed more homogeneous and easy to digest and assimilate animals.

Production of granular materials: In construction, ceramic and other industries are used to granate, which facilitates molding or subsequent processing.

Grauling of processed plastic: Used in industry for processing plastics. Revised plastic fragments or powder turn into plastic granules using a granulator for easy processing.

Pharmaceutical industry: The disk granulator can also be used for moist granulation in the process of pharmaceutical production. Helps improve the quality of drugs and the stability of pharmaceutical processes.

Disk granulator design based on the use of viscosity and humidity of materials, in combination with the rotation of the disk and its adjustable inclination, which allows the material under the influence of centrifugal force, gravity, friction and other forces form in balls or granules. This method of manufacturing granules is easy to operate and relatively inexpensive, which makes it indispensable equipment in many production processes.

To effectively increase the life of the disk granulator, usually its good maintenance and proper operation are required. Subject to these conditions disk granulator can reach many years or even decades. However, the specific service life also depends on the actual conditions of use. Below are some methods, which we summed up about how in everyday use and maintenance of a disk granulator you can increase its service life.

Regular service:

– Follow the recommendations of the manufacturer on regular verification and maintenance.

– Check and adjust the key components of the disk granulator regularly, such as drive belts, bearings And gears.

– Clean the disk and other components, to prevent corrosion or clogging due to the remains of the material.

Reasonable operation:

– Act in accordance with the operating manual and make sure, that operators know the correct methods of using equipment.

– Avoid overloads, Make sure, that the amount of material is added reasonably, to avoid disk overload.

– Before starting, check the equipment for unusual sounds or vibration and eliminate problems on time.

Environmental control:

– If possible, use the granulator in dry and well -ventilated conditions, to reduce the effect of humidity and corrosion substances on equipment.

– Protect equipment from too high or low temperatures, since extreme temperatures can negatively affect its performance.

Using suitable materials:

– Use materials, corresponding to the disk granulator, Avoid processing too abrasive or sticky materials, To reduce wear.

Timely replacement of spare parts:

– Replace the worn details in time, Such as scrapers, gears and bearings, to avoid excess wear, which can damage other parts.

Vocational training:

– Make sure, that operators undergo suitable training to understand the proper operation and maintenance of equipment.

Record of service history:

– Write down the time and conditions of each service and replacement of spare parts to track the condition of the equipment and timely preventive maintenance.

Increase in granulator service life – This is a long process, which requires your constant attention and compliance with these service measures. This will not only help significantly increase the life of the disk granulator, but also keep it in good working condition, will increase productivity and product quality.

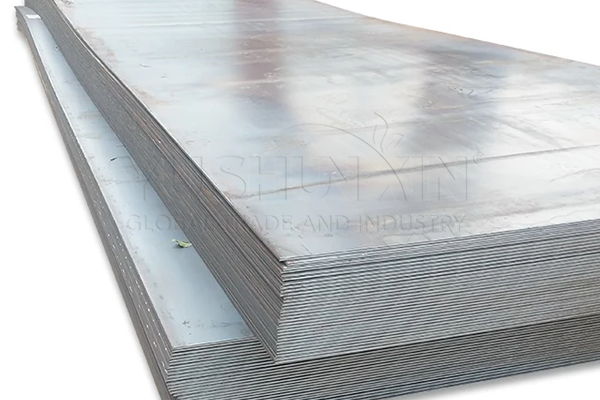

Disk granulator can be like a closed, so open. We count, that a closed design better controls the quality of granules and helps to reduce the formation Dust. The design does not just put the lid on the disk granulator, And adds the house. A simple understanding is to cover the entire part of the granulator with a sheet iron case, which can effectively prevent dust distribution. Because if it is completely closed, the material will not be able to get into the disk granulator.

Answer: Disk granulator From steel Q235B.

Q235b – This is the material of low -carbon steel, which is determined in the Chinese standard GB/T 700 and is one of the most widely used carbon structural steels in China. Our factory uses a disk granulator made of steel Q235B. Its characteristics are equivalent to the American standard ASTM A36 and international ISO standard 630 E235B. Steel Q235B, as a widely used low -carbon material, It has the following features when using such equipment for the production of fertilizers in the production of such equipment, Like a disk granulator:

– Suitable mechanical properties: Q235B has good plasticity and viscosity, capable of maintaining mechanical pressure and shock loads, disk granulator arising in the process, ensuring normal work and production safety.

– Good welding: In the production process disk granulator often required welding of parts. Due to the low carbon content and excellent coil of Q235B, it is easy to connect various parts. Besides, welded seams are reliable, which reduces the risk of deformation and cracks in welded joints.

– Economic efficiency: As a common material of carbon structural steel, Q235B is reliable in operation. It provides the durability and performance of the disk granulator, while remaining very affordable in price, which guarantees a high price-quality ratio.

– The possibility of configuration: Q235B steel is easily processed and formed, which allows you to cut, Flexible and molding according to specific design requirements of the disk granulator to satisfy various constructive and dimensional needs.

The overall chemical composition of steel Q235B:

– Carbon (C): 0.12% – 0.20%

– Silicon (And): ≤ 0.30%

– Manganese (Mn): 0.30% – 0.70%

– Phosphorus (P): ≤ 0.045%

– Sulfur (S): ≤ 0.045%

– Iron (Fe): The rest of the content

Small amounts of such elements, Like Nickel, copper, chromium, Molibden and others, may be present in the form of impurities. However, these elements are usually not added intentionally as alloying components, and their content, usually, Very low.

What is the diameter of the granulator SXYZ-3600?

Disk granulator SXYZ-3600 has a diameter 3600 mm. This size makes it ideal for working with large volumes of materials. Larger diameter not only increases performance, but also enhances the effect of mixing and granulizing materials in the plate. It means, that the granulator is able to process more material in one operation. General performance is increasing, and the number of necessary operations is reduced. Suitable for mass production of pellets.

What is the height of the side of the dish?

The height of the frying pan - 450 mm. This design takes into account the movement of materials in the bowl and safety in the granulation process. The moderate height of the sides guarantees, that the material will not be easy to get enough sleep when rotating at high speed. At the same time, it provides enough space for uniform distribution and granulation of materials. A higher edge also reduces the waste of the material, making the granulation process more efficient and controlled.

What is the speed of the SXYZ-3600?

SXYZ-3600 rotation speed is 13 rpm (rpm). This speed is carefully calculated to optimize the granulation effect. The moderate speed of rotation provides the material with sufficient centrifugal force in the disk for the formation of homogeneous particles. This speed not only optimizes granular efficiency, but also reduces the wear of the machine and energy consumption. What makes it an effective and durable device.

What is the engine power of this model?

Sxyz-3600 melt granulator is equipped with a power engine 18,5 kW. A powerful engine guarantees stable operation of the machine at high loads and provides a constant supply of electricity for the granulation process. Choosing the right engine power, SXYZ-3600 is able to achieve a balance between energy efficiency and performance. This not only reduces operating expenses, but also reduces environmental impact, What makes it an environmentally friendly and economical choice.

What is the production capacity of SXYZ-3600?

SXYZ-3600 performance is from 4 to 6 tons in time (subject). Such performance makes it suitable for large -scale industrial use and can satisfy various production needs. High performance is achieved due to an optimized design and an effective working mechanism. It means, that you can process large volumes of material in a shorter time, Increasing productivity and profitability.

What type of gearbox is used in SXYZ-3600?

SXYZ-3600 uses gearbox type ZQ400. This gearbox is well known for its high efficiency and durability. Can guarantee, that the machine will maintain stable operation in various operating conditions. The choice of the gearbox directly affects the overall performance and life of the machine. The velocity gearbox ZQ400 provides the necessary function of reducing the speed of the machine due to the optimized gear ratio and strong design. Provides a smooth and effective granulation process.

What are the sizes of the SXYZ-3600?

The overall dimensions of the SXYZ-3600 are the length 4100 mm, width 2900 mm and height 3800 mm. These sizes make them suitable for installation in various industrial conditions. Despite its large size, It was developed for easy integration and installation. The well -thought -out design not only saves place, but also ensures the convenience of operation and ease of maintenance.

Is SXYZ-3600 suitable for all types of materials?

The SXYZ-3600 disk granulator is designed for processing of a wide range of materials. However, to ensure optimal performance and avoid potential compatibility problems, we recommend that you consult with us before use. The physical and chemical properties of various materials can affect the results of granulation, Therefore, it is important to understand the scope of equipment. It also helps to extend the life of the equipment and reduce unnecessary wear.

What service is necessary for optimal performance?

To ensure the best productivity of the SXYZ-3600 plane, regular Maintenance. General maintenance measures include:

- Check the engine and gearbox: regularly check the working condition of the engine and gearbox, To make sure of their normal work.

- Lubricate moving parts: All moving parts must be regularly lubricated, to reduce friction and wear.

- Clean and inspect the equipment: Regularly clean the pallet of the remains of materials and check the wear of the equipment. Replace damaged parts immediately.

When choosing a disk granulator model, the key factor is the compliance of performance. The choice of lower performance will lead to non -fulfillment of orders, And the choice of greater productivity will lead to the simple equipment and the revenge of electricity. How to choose a model depending on performance? For example, If I need to produce 10 tons per day, what disk diameter should I choose? Performance Tarelly granulator Depends on the diameter of the disk. To determine the correct diameter of the disks, you must first calculate the actual time performance.

How to calculate the actual hourly performance?

Actual hourly performance = planned daily volume of production is an effective number of working hours per day.

Let us give an example:

- If your planned daily production volume is 10 ton, And your factory actually works 8 hours a day (without taking into account time for equipment maintenance and replacement of raw materials, not 24 hours). Then your actual hourly performance = 10 ton ÷ 8 hours = 1,25 Tons/hour.

- If your region has frequent interruptions with electricity or unstable deliveries of raw materials. The factory can only work stably 6 hours a day. Then your actual time performance = 10 ton ÷ 6 hours ≈ 1,67 Tons/hour. At this time, you need to choose a model with higher performance, To avoid the discretion of the daily target indicator of production due to the insufficient number of working hours.

How to coordinate the diameter of the disk of the disk granulator you have chosen with actual hourly performance?

Actually, Data on the performance of the plane granulator are "theoretical meaning". Actually, The characteristics of raw materials and operating competence will be affected by it. We usually recommend reservating 10–20% of the power. For example, If you need it 1,25 Tons per hour, Select a model with a capacity of 1-1.5 tons per hour, To avoid failures, caused by work with full load.

If you work on a shift 8 hours (Actual time performance 1,25 Tons/hour):

1,25 tons/hour quite corresponds to the diameter of the disk 2000 mm (Theoretical hourly performance 1-1.5 tons/hour). A disc of this diameter also produces 12-15 tons per day, which perfectly corresponds to the daily need for 10 ton. The reserve of production capacities at the level of 10–20 was also reserved %.

If you have a 6-hour work schedule (Actual time performance 1,67 Tons/hour):

1,67 tons/hour exceeds the maximum theoretical performance of the disk with a diameter 2000 mm (1,5 Tons/hour). Disk granulator must be upgraded to the diameter 2800 mm (Theoretical watch performance 2-3 Tons/hour). A disk of this diameter is suitable for 6-hour daily performance 12-18 ton, that the need for 10 tons. If you are interested in this model of a disk granulator, Contact us.

If you can guarantee stable work during 8 hours a day, then the choice of disk diameter 2000 mm will be the most economically profitable. With a short working time or unstable raw material, disk diameter 2800 mm is more reliable. Avoid the replacement of equipment due to insufficiency of production capacities at the late stage. To obtain more detailed information about the plane granulator, click the button below.