Solution:Production of granules of organic fertilizers

- Performance: 1-30 T/hour.

- Price: 390 000 rub. – 66 000 000 rub.

- Raw materials: Feces, Organic waste…

- Areas of application: Organic fertilizer production enterprises, farms, countryside…

- Production line process: Fermentation, crushing, screening, Dosage, Grinding, mixing, granulation, screening, Coating, package…

Organic fertilizer pellet line can turn organic waste into granular fertilizers by fermentation, grinding, mixing, Grauling, begging, Drying and cooling, coating, packaging and other processes.

The main raw material for organic fertilizers is animal manure. Some animals have a poor digestive ability and can only consume 25% nutrients, And the rest 75% nutrients in the stern will be displayed with feces. Thus, Cooked granules of organic fertilizers are rich nitrogen, Phosphorus, potassium, organic substances, amino acids, proteins and other components. It can not only provide nutrients, necessary for the growth of agricultural crops, but also improve soil condition.

The entire production line for granulizing organic fertilizers includes Many equipment. Raw materials, which you use, differs, and equipment, which you need, Also different. We can provide you with a comprehensive solution for the production line. The volume of production, which you want to achieve, defines the requirements for equipment power, what will affect the price of purchase. If you want to know the specific cost and price of the entire production line, You can Send us an email. We will have professional staff, To answer you.

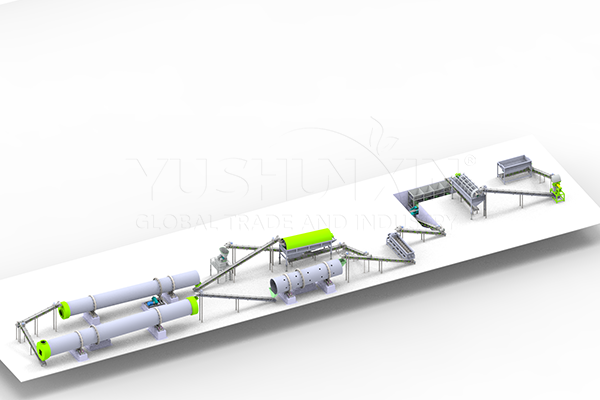

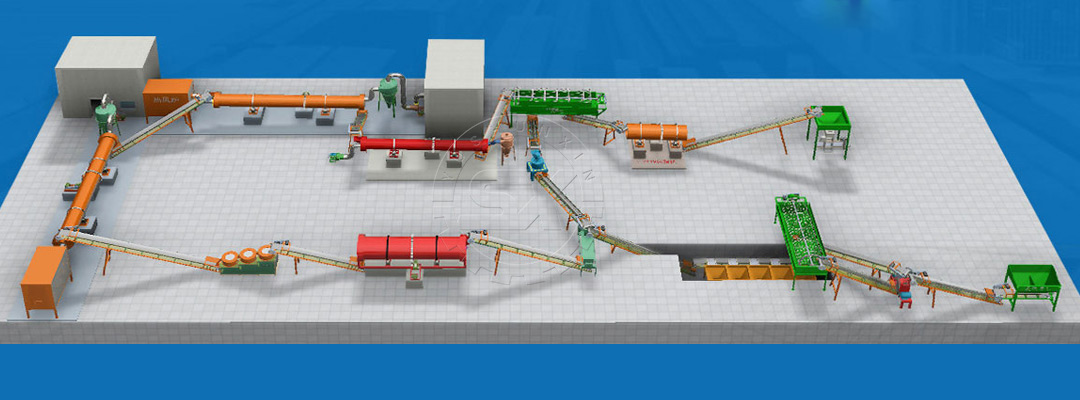

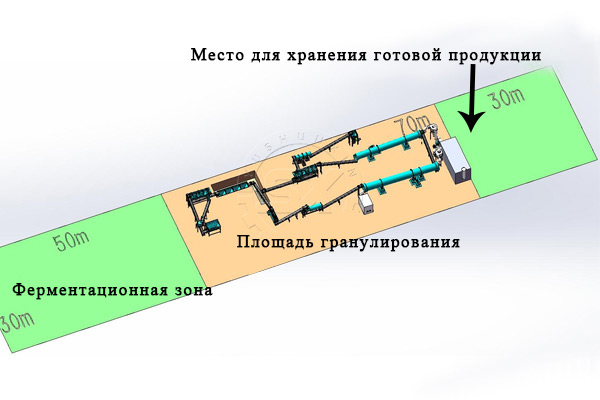

What equipment is included in the set of all the granular organic fertilizer line provided to you?

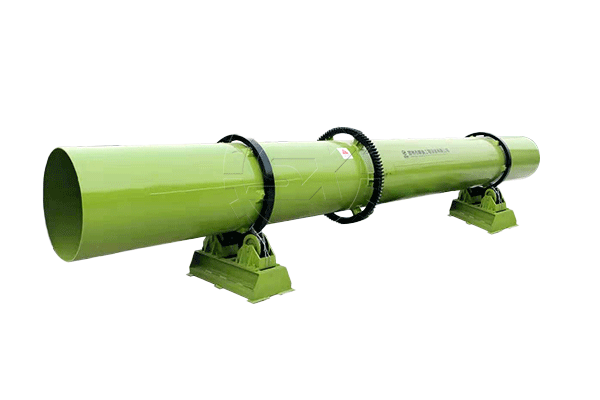

The first is a revolving and throwing machine, necessary for the fermentation process. This can help you better ferment the material. Second - you need an excavator loader and automatic feeder. He transports fermented and mature raw materials to the granulation zone, And feed evenly.

Then you need a grinder, to grind raw materials to size, suitable for granulation. Crushed raw materials must be sifted using a sifting machine, And if it is too great, It must be chopped again. Then through Multi -tier dosing system It is placed in the mixer along with newly added nitrogen, phosphorus and potassium, microelements, biological bacteria and t. e. for uniform mixing.

After the mixing is completed, it can enter the granulation granulator. Made pellets must be cooled and dried. After that, how this process is completed, Another sifting is required to scatter suitable particles. Inappropriate should be returned to the grinder for crushing and repeated granulation.

Qualified particles are subjected to the last process, coating. After applying the coating, it can be packaged, Store and sell.

What is the role of silage configuration for you? Is it possible not to have this device?

First of all, This can guarantee, that in the production process there will always be a batch of fermented materials, awaiting grinding. Ensure the continuity of production and increase the efficiency of production. According to the conclusion, made of our many years of experience, It can increase production efficiency on 80%.

Secondly, He can unload the materials evenly. You know, This is one of the keys to the quality of your finished product. This can make the size of the obtained particles not very different. But can also reduce the use of workers, reduce production costs.

Therefore, we do not recommend that you avoid this device, To save money. You can do without an excavator of the loader. His work is simple, And you can replace it with some workers.

How do you choose granulation equipment?

There are many methods of granulation of organic fertilizers, and the granulation equipment used is also varied. By the principle of formation, we divide them into two categories: agglomeration method and extrusion method. The use of the agglomeration method is presented drum And disk granulator. The most widely used extrusion granulator is Two -willed granula And Granulator device with a flat matrix.

How do you choose? The most important, You are based on the suitability of the material, which you process. Only in this way can you maximize energy conservation and reduce emissions, and also increase the efficiency of your production.

Can you refuse to buy drying equipment in order to save money?

We do not recommend you to do this. Drying equipment It is very necessary on the line for the production of granules of organic fertilizers. It has three functions:

Reduce moisture content in granular organic fertilizer.

The moisture content in the raw materials of organic fertilizers is relatively high. Despite, that the water content in the material was reduced during the previous process, It was reduced only to water content, suitable for your production pellet. Drying equipment will additionally reduce the water content in granular fertilizer. Thus, The process of production of granular organic fertilizers is inseparable from the dryer and cooler.

· Extend the shelf life of particles.

Granular organic fertilizers as goods require storage time after their production, packaging for sale and subsequent entry into crops. This is necessary, so that the granular organic fertilizer is preserved as long as possible., and the nutrients contained in it were preserved as long as possible. Loss of nutrients often occurs due to disappearing and reducing the strength of the particles. After drying, the period of storage of particles can be effectively extended. Thus, The process of drying the line for the production of granular organic fertilizers is good for extending the storage period.

So, to save, what equipment you can not buy?

The first is a packaging machine. Its content of work is simply. You can buy a semi -automatic packaging machine or hire workers for packaging.

Then follows a car for sifting particles. If you have no requirements for the size of granular organic fertilizer, which you are selling, You may not use this equipment.

To learn more about ways to save on the purchase of equipment, You can consult with our engineers. They have many years of experience and will be able to provide you with a satisfactory decision.

Do granulated organic fertilizers have a market space?

Granular organic fertilizers are not easy to agglominated and suitable for transportation over long distances. This is an advantage, which powder of organic fertilizers does not have. You can sell in more remote places, not limited to spatial distance. The market is extensive.

Granular organic fertilizer can slowly release the effect of fertilizer, And this is more convenient when introducing fertilizers. It is not easy. This is the choice of most farmers in today's era, And the market space is very great.