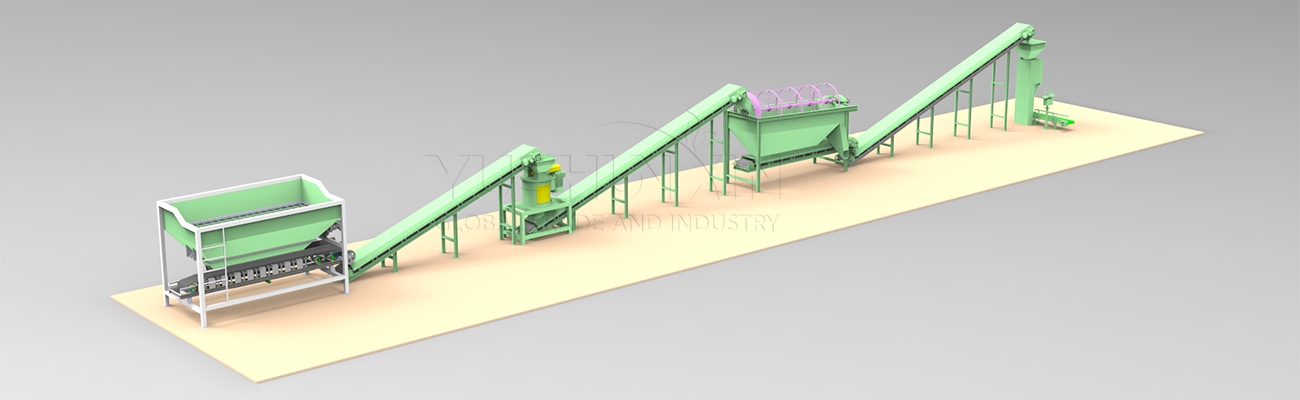

The line for the production of organic fertilizers from chicken droppings

- Performance: 1-30 T/hour.

- Price: 390 000 rub. – 66 000 000 rub.

- Raw materials: Chicken droppings, Organic waste, sawdust…

- Scope: Production of organic fertilizers.

- Production line process: Composting, Dosage, crushing, mixing, granulation, screening, Coating, package…

If you want to invest in an organic fertilizer production line, Organic fertilizer from chicken droppings will be a good choice for you. Investments in the line for the production of organic fertilizers from chicken droppings - a potential project, which can bring significant economic benefits. If you are interested in obtaining more detailed information, Please, Contact us. We will provide individual solutions in accordance with your needs.

In modern agricultural production, organic fertilizers pay more and more attention due to their protection of the environment and stability. Chicken droppings are high -quality organic fertilizer raw materials. Its processing and use are of great importance for increasing the fertility of the soil and increasing the yield of agricultural crops. As a manufacturer of equipment for the production of fertilizers, We have deep research and practical experience with working with Production lines organic fertilizer from chicken droppings. Choose us, To realize your ideal production of environmentally friendly fertilizers.

What methods will help you determine, whether the fermentation of the chicken dropped?

Fermentation of chicken droppings is an important stage in production organic fertilizer from chicken droppings. The quality of chicken -drop fermentation determines the quality of the final product of the organic fertilizer of chicken droppings. So you need to learn how to correctly judge the completion of fermentation. This ensures smooth development of the subsequent process of production of organic fertilizers.

- 1

Temperature. During the process enzymes chicken droppings will increase and after a while stabilized. When the temperature inside the compost gradually drops to the ambient temperature, This usually means, that fermentation is approaching to an end.

- 2

Color. The initial chicken label usually has a brighter color. After fermentation, it will become dark brown or black.

- 3

Scent. The process of fermentation reduces the level of ammonia and other harmful gases in chicken litter. Thereby eliminating its smell. Mature compost will have an earthy aroma.

- 4

Texture. Mature compost is loose and easy. And particles are relatively homogeneous.

- 5

Meaning pH and the ratio of c/n. The value of pH of mature compost is usually neutral, and the ratio of carbon and nitrogen is close to the perfect 20:1.

Line for the production of powdered organic fertilizers from chicken droppings – Suitable for small and medium poultry farms.

The main technological process of the production line includes the stages of mixing chicken and auxiliary materials, quick fermentation, Grinding the material, Sorting and packaging. You need to use mixers, Composters, crushers, sifting cars, packaging machines and other equipment for the production of fertilizers. Thanks to this process, chicken droppings with poultry farms turn into a highly effective organic fertilizer. This not only solves the problem waste disposal on poultry farms, but also reduces environmental pollution. The created additional economic value can increase your profit.

For small and medium poultry farms, the line for the production of powder -shaped organic fertilizer from chicken droppings has advantages of low cost, simplicity of operation, environmental protection and stability. This helps farmers turn costs and environmental pressure into profit. Besides, Market demand for organic fertilizers is growing, since consumers are increasingly taking care of health and environmental protection. Consider the future development of your chicken farm in terms of long -term interests and strategies for sustainable development. Investing in a line for the production of organic fertilizers in the form of powdered chicken droppings - a good choice for you.

The line for the production of organic fertilizers from granular chicken droppings is the best solution for manufacturers of organic fertilizers.

Granular fertilizers are used in the market a little more popular. The process of its production consists of a much larger number of stages, than the process of production of powdered organic fertilizers. Fermented materials are crushed and mixed. Then it is turned into granules through the granulator. Subsequently, granular fertilizer must be dried and cooled. And go through the sorting machine, to draw out quality products. Finally, granular fertilizer is packaged and stored ready for sale.

In the market, organic fertilizers are represented in granular form, convenient for transportation and making. More suitable for your commercial circulation. Besides, A high degree of automation of our line for the production of granules of organic fertilizers facilitates the work and control of employees. Save your cost of labor in production. Our line for the production of organic fertilizers from granular chicken droppings provides you with stable and mature technical support in the market of organic fertilizers.

What is the current price of organic fertilizer from chicken droppings in the international market?

The price of organic fertilizer of chicken droppings is affected by many factors. Region, Fertilizer quality, package, The volume of wholesale purchases, Demand and supply in the market, etc.. Since the cost of the production of granular organic fertilizer from chicken droppings is high, Its market price will also be higher. Generally speaking, Powder organic fertilizer from chicken droppings can cost from 100 to 300 dollars per ton. Granular can cost within 200-500 US dollars per ton.

If you invest in a line for the production of organic fertilizers from powder chicken droppings with annual performance 5000 ton, How much time you will need, to return your money?

Investment and building costs for the production line for powder organic fertilizers are relatively small. The cost of building a full line for the production of powdered organic fertilizers is about 70 000 US dollars. The total average cost of production and the marketing value of each ton of powdered organic fertilizer from chicken droppings is about 50 US dollars.

If you are selling at a price 100 dollars per ton. The annual production volume is 5000 ton. Thus, Your annual income is about 500 000 dollars. Excluding costs and other expenses, annual net profit is 250 000 US dollars. In ideal circumstances, you can return your money approximately through 4 months.

If you invest in a line for the production of organic fertilizers in the form of granular chicken droppings with annual performance 10 000 ton, How much time you will need, to return your money?

The construction of the line for the production of organic fertilizers in the form of granular chicken droppings is around 200 thousands of US dollars. Its production will cost more. We calculate, Based on production and marketing costs per ton in the amount of about 70 US dollars.

If the price, which you sell in the market, It is 120 US dollars/ton. Then with an annual production volume 10 000 tons your net profit will be 500 000 US dollars. Recoup costs and start making a profit, you can after about six months.

Specific conditions of the production line organic fertilizer from chicken droppings and Necessary equipment must be taken into account depending on your real situation. If you plan to invest in a line for the production of organic fertilizers, Please, Contact us. We will select the production line, which is suitable for you, Based on your situation. If you want to know payback period and t. e in., We also have professional engineers, who will calculate it for you. Contact us, to start your journey through the production of green fertilizers!