Line Production filler for a cat's toilet from sawdust

With the rapid development of the economy of pets, the market demand for products for pets, Especially fillers for cat toilets, It grows steadily. Filler for cat toilets from sawdust, as an environmentally friendly product. Consumers prefer it due to its renewable nature and excellent absorbing properties.

How Professional manufacturer of production equipment, we launched an effective and fully automated Production line filler for a cat's toilet from sawdust. This production line combines innovative technologies, which not only significantly increase the efficiency of production, but also provide stability and high quality products. At the same time, production costs are reduced. Help you increase productivity and increase competitiveness in the market.

What wood raw materials can be used to make filler from sawdust for a cat toilet?

The most important raw material in the production line filler for a cat toilet from sawdust is sawdust. However, the cost will affect specific types of wood used, accessibility, Environmental requirements and requirements for the characteristics of the final product. Below are some types of wood raw materials, usually used by producers of fillers for cat toilets from wood chips:

- 1

Pine wood: is one of the most commonly used raw materials for the manufacture of sawdust toilets. Since it has natural absorbent properties and has coniferous aroma, He absorbs moisture and neutralizes smells.

- 2

Fir: also chosen due to its absorbent ability and aroma. However, due to the potentially pitch, he can adversely affect the health of some cats and people.

- 3

Birch: also a popular choice due to good absorption and softer smell.

- 4

Revised wood: In some cases, processed and processed wood chips (For example, furniture, Construction waste) can be used as raw materials for the production of fillers for cat toilets.

- 5

Other wood materials: In addition to the above ordinary wood, other types of wood materials can be used. Given that, that they meet the requirements for absorption, safety and biodegradability.

In addition to the above main wood raw materials, In the production of fillers for cat toilets, some auxiliary substances can also be used. For example, Some glues, Politing agents or flavorings, improving the characteristics or attractiveness of the product. You can add natural plant fibers as a binder, so that wood granules retain the shape. To reduce the amount of dust, you can also add non -hazardous dusting agents.

A wood crusher will help you process wood into chips with particles, suitable for granulum toilet!

Opel for a cat toilet present certain requirements for the size of the particles of sawdust. Our Wood crushers They can grind your raw materials to size, suitable for granulum. Inside the wood chopper, we designed an effective knife system. Wood materials can be quickly cut into small wood chips. And adjust the size of the particles of the output chip in accordance with your needs. Satisfy your production needs.

You can also be calm for its safety. Our wood grinders are equipped with security functions, ensuring the safety of your operators. The overall design of the equipment is convenient for the user, easy to operate and maintain. We will help you produce high -quality granules made of woody woodwater toilets.

Display the process of crushing wood

What granulator will help you produce granules for cat toilets from sawdust?

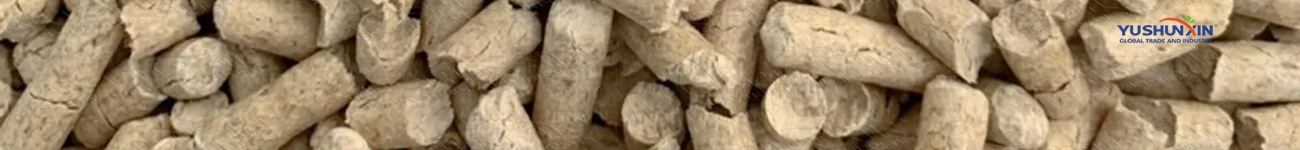

Most of the production of cat filler from sawdust, represented in the market, They have a cylindrical shape. The filler for a cat toilet of this form has a high absorption ability and it is not easy to break it. If you are also going to produce a filler for a cat toilet of this form, The best choice will be Plonulator with flat matrix. On our production line for a cat's toilet filler, a granulator with a flat matrix is used.

He presses sawdust into particles through physical extrusion. When raw materials enters the plate of the mold through the boot hole, It is pushed into the opening of the form under the action of the clamping wheel. When the matrix rotates, raw materials are constantly compressed in the opening of the matrix. Cylindrical particles of a certain length and diameter are formed. After that, how particles are squeezed through the openings of the matrix, They are cut down below the cutter. Make its length and the size of the particles uniform.

As a line for production, filler for a cat's toilet from sawdust helps you produce high -quality particles of fillers for cat toilets?

The technological process of our line for the production of fillers for cat toilets from sawdust usually includes the following main stages. At first, your wood raw materials are crushed with a crusher to obtain fine wood chips. Then the wood chips are sorted to remove impurities and oversized particles, to ensure the quality and consistency of a cat toilet. The next stage is high -temperature drying. Adjust the moisture of the chip to a suitable level, To facilitate the granulation process.

Dried wood chips are granulated through a granulator with a flat matrix. This process allows you to add natural binders or use wood as a lignin of your own lignin. Finally, Formed granules for a cat toilet must be cooled and remove excess powder. Particles, not compliance with criteria, then separated by sifting. Particles of sawdust for a cat toilet, relevant to the requirements, can be packed and sold by you.

What are the advantages of wood chips that are popular in the fillers from wood chips in comparison with other types of fillers for cat toilets?

A filler for a cat toilet made of wood chips has a soft surface and delicate for cat paws. Provides more comfortable use.

Although the initial cost of a filler for a cat toilet from a wood chip can be slightly higher, than some types of cat fillers. But its effective absorption and grasping often mean, that it is used in fewer. So in the long run it may turn out to be more economical.

What is the cost of the line for the production of fillers for cat toilets from sawdust with performance 2,5 subject? How much time will it take, to recoup investments in this production line?

There are many factors, which should be taken into account when investing in the production of filler for cats from sawdust. We are currently approximately evaluating, that the construction of the production line filler for a cat toilet from sawdust with performance 2,5 t/h will cost about 500 000 US dollars. This includes renting a site, production equipment costs, water and electricity, labor and t. e.

Suppose, that this production line works 8 hours a day 20 days a month. Then the monthly theoretical performance will be 400 tons/month. Depending on the market conditions of the price of a feline filler from sawdust, can differ significantly. We assume, that the vacation price per ton is 500 US dollars. Besides, There are operating expenses, which we take in size $250 per ton of products.

Then this production line can bring you about 200 000 dollars per month. Minus the costs and t. e. Monthly net profit is about 100 000 US dollars. If the cost of building a line for the production of fillers for cat toilets from wood chips is 500 000 US dollars, then the payback of investments will take everything 5 months. This is a very profitable investment for you.

In addition to the production line filler for a cat's toilet from sawdust, we can also provide you with other solutions for the production lines for fillers for feline toilets. For example, Bentonite fillers for cat -toilets, Fillet production line for cats from tofu and t. e. If you need it, Please, Contact us, to get detailed information and prices for the production line.