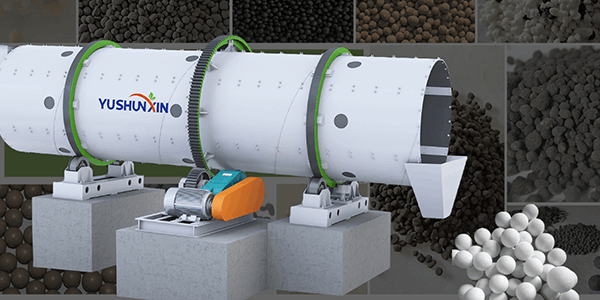

Drum granulator

- Power: 5,5 – 37 kW

- The size of the particles: 3 – 6 mm

- The degree of granulation: 90% +

- Production capacity: 1 – 30 subject.

- The size of the particles of raw materials before granulation: 50 oven.

- Moisture content of raw materials before granulation: 20% – 40%

- Equipment material: Carbon steel Q235, Rubber material lining

- Application: Manure animals, The remains of biogas, humus, brown coal, NPK, bentonite, Mineral fertilizers…

A rotating drum granulator is a highly effective granulator, widely used in Organic production lines, complex and inorganic fertilizers. It is highly performance, stable work, high efficiency of granulation (The degree of granulation is more 70%) and high adaptability. The equipment is characterized by a simple design and ease of operation, which provides continuous and automated production. Besides, The rotary drum granulator can also be used to prepare granules in a pharmaceutical, chemical, compound feed and other industries.

Manufacturer Shunxin, specializing in the production of rotary drum granulators more 30 years. We have rich experience in production and the possibility of individual setting. We offer high -quality equipment for Favorable price. Contact us, To learn about the purchase of a rotating drum granulator!

Let's briefly consider the granulation process in a rotating drum granulator!

Drum type granulator is granulation equipment, which is great for large -scale granulation. How it works? We will give you a brief introduction. The material enters the drum granulator through the boot hole. Since the granular drum of the granular body continues to rotate, the material will continuously rise to a certain height in the drum, and then fall freely. The rotation of the drum causes a fall in the material and its collision. Under the influence of appropriate humidity and binder, small particles gradually stick together in balls. As the granulation process continues, the particles increase in size and reach the desired size.

Finally, ready -made granules are unloaded through the unloading hole. After sifting on a sifting car small particles, Not compliance with the requirements, can be returned to further granulation. The degree of granulation of our drum granulator can achieve 70%. The whole process is effective and continuous, which significantly increases production efficiency. This helps you achieve stable large -scale granulation production. If you are interested in this device and you want to know a specific price, Contact us, By pressing the button below.

How much does our drum granulator cost?

After a brief familiarization with drum granulators you, probably, Very interested in their price. The price range for drum granulators in the market is quite wide: from 1000 to 7000 US dollars And even higher. It depends on a number of factors, among which the key is the size of the drum granulator.

- For example, Small drum granulator with performance 1-2 Tons per hour. The diameter of their drum is usually 1-1,5 meter, And the length - 3-4 meter. Their price is relatively low, Usually near 1000 US dollars. This type of equipment is suitable for small businesses, experimental research or small -scale initial production.

- Medium drum granulators usually have performance 3-8 tons in time. The diameter of the drum is 1.8–2.5 meters, length - 5-7 meters. Their price varies from 1000 to 4000 US dollars. They are able to satisfy daily production needs of medium -sized enterprises and are widely used in the market.

- Large -sized rotary drum granulators have a capacity of more 10 tons in time. The diameter of the drum exceeds 3 meter, And the length - 8 meters. The price will be more 5000 dollars. If you are a large fertilizer production plant or chemical company, You can purchase and use this type of granulation equipment with a rotating drum to meet the needs of your large -scale production.

How much high -quality organic granular fertilizer can produce a granulator drum per hour for you?

The performance of our drum granulator is 1-30 T per hour, Different models can produce different performance for you per hour. at present. We have five popular models of drum granulators, who are very popular among customers. This is SXZGZ-1240, SXZGZ-1560, SXZGZ-1870, SXZGZ-2080, SXZGZ-3210, These five drum granulators.

If your production need is 1-3 subject, We recommend that you choose the drum granulator SXZGZ-1240, which can fully satisfy your needs and consumes everything 5,5 kW. The performance of the drum granulator SXZGZ-1560 is 3-5 subject. If you have a small factory, You can choose this. Consumes 11kW per hour.

If your plant is positioned as a medium -sized plant, then our drum granulator SXZGZ-1870 will be a good choice for you. He can produce for you 5-8 tons in time, Consuming only 15 kW. There is also a drum granulator with a capacity of 8-15t/h, Model SXZGZ-2080, Power consumption 18.5 kW. It is also ideal for large -scale production in your medium -sized business.

If you are a major factory, We recommend that you choose the latter, Drum granulator SXZGZ-3210. He can produce for you 15-30 tons per hour and consume 37 kW.

| Type | Total power (kW) | In diameter (mm) | Length (mm) | Mounting angle | Rotation speed (rpm) | Performance (subject) |

|---|---|---|---|---|---|---|

| SXZGZ-1240 | 5,5 | 1200 | 4000 | 2-5° | 17 | 1-3 |

| SXZGZ-1560 | 11 | 1500 | 6000 | 2-5° | 17,5 | 3-5 |

| SXZGZ-1870 | 15 | 1800 | 7000 | 2-5° | 11,5 | 5-8 |

| SXZGZ-2080 | 18,5 | 2000 | 8000 | 2-5° | 11 | 8-15 |

| SXZGZ-3210 | 37 | 3200 | 10000 | 2-5° | 9,5 | 15-30 |

What methods can help you control the size of the particles, produced by the drum granulator?

Correct the properties of raw materials:

- Input raw particles size directly affects the size of the particles of the final product. The smaller the particles of raw materials, all the easier to mold products with small particle sizes.

- The moisture content of raw materials It is also very important. Correct humidity can strengthen the power of the connection between the particles of raw materials and help small particles aggregate into larger particles.

The parameters of the control drum:

- Rotation speed adjustment allows you to change the rate of particle formation and collision intensity between particles. When rotation speed is higher, the force of the collision between the particles increases. This can lead to fragmentation of small particles or accelerated aggregation between particles, As a result, smaller particles are formed. When the drum rotates slowly, particles have more time for growth inside the drum, forming larger particles.

- Change the angle of tilt of the drum, to set up trajectory and the time of stay of the material in the drum. When the angle of inclination is larger, the time of stay of the material is shorter and the smaller particles are usually formed. The smaller the angle of inclination, the longer the time of stay, which contributes to the formation of larger particles.

- Optimize the internal structure of the drum (For example, lifting plates, Partitions, etc.. e in.), To change the stream mode and mixing materials. The lifting plate can improve the mixing effect and the frequency of the circulation of materials, and also contribute to the uniform formation of particles. Partitions can share various areas inside the drum, influencing the flow of materials and the growth of particles.

What granulation process is used in our drum granulator, To help you produce high -quality organic granular fertilizers?

Our drum granulators use for you the process of wet granulation. Adding a binder and rotating cylinder. As a result, pressure will be created between the particles of the material, and they will be agglomerated in balls and, finally, make a high -quality organic granular fertilizer for you. The binder may be water or steam. You can add a binder before the start of granulation or after, how the material gets into the drum granulator.

How the binder is added after, how the material enters the drum granulator?

On one side of the input opening of the drum granulator will be a tank with a coating, containing additives. The pipe will transport additives from the tank for applying the coating to the loading opening of the granulator. This pipeline is usually equipped with a pump or other pressure device for regulating the flow rate and glue supply speed.

Inside the eardrum at the end of the pipe, a sprayer or nozzle will be installed. These devices are equipped with accurate dispersal holes or nozzles tips, which allow you to regulate the spray angle and pressure. When the material enters the drum through the feed hole, The internal spray is evenly spraying the glue to the surface of the material.

What special production processes are used in the production of our drum granulator, To help you reduce equipment losses?

For facing the drum of the drum granulator, we have two options: Facing with polyethylene rubber with ultra-high molecular weight of UHMW-PE, And the other – Conducting with acid -resistant stainless steel. They can be chosen in accordance with your needs.

To prevent the reverse flow and leakage of the material, We installed stop rings for you at both ends of the drum granulator. Stop ring at the exit from the eardrum can not only increase the thickness of the material in the cylinder, but also extend the time for you to stay material in the drum granulator, So the finished granular fertilizer, which you will receive, will be more beautiful.

How to serve a drum granulator, to extend the service life of your drum granulator?

Before starting the car, lubricate the gear of the drum granulator with yellow dry oil. The drum granulator gearbox also needs to be filled once before use by transmission oil, And you need to change it every four months. On the surface of the belt of the drum granulator, it is necessary to apply yellow dry oil once every seven days, And the bearing nest should be painted with yellow, dry oil every three months or replaced with new yellow dry oil.

Compliance with the foregoing may extend the service life of your drum granulator, reduce equipment loss and, Thus, reduce production costs.

Some general problems of the drum granulator and their solutions.

· The case of the machine is not leveled.

If this problem arises, it is necessary to check the supporting and holding wheels. Repair or replace it depending on the degree of wear.

· The gears are shifted.

Under normal conditions, this problem has two reasons: One of them is the wear of a small gear, and the other is damage to the connection between the large gear and the cylinder. You need to check them one by one. If this is the cause of the gear, You need to install the gear in the reverse order, when both sides are worn out, You need to replace it with a new. If this is a connection problem, You need to deal with her.

Whether we provide individual services for the manufacture of a granulation line with a rotating drum?

Of course there is. You can tell us your production needs, Initial capital, location, etc.. e. We will design for you the most suitable line for the production of granulators. We will do our best, To reduce the project cycle and complete the production and installation of all equipment on the production line as soon as possible, so that you can open your business as soon as possible.

If you want to produce granular fertilizers of a higher concentration, We recommend that you equip disk granulator, If your budget is sufficient. Connect the drum granulator with a disk granulator sequentially for secondary granulation, Increase production efficiency and fertilizer quality.

The Russian customer ordered the SXZGZ-3210 drum granulator for the production of limestone granules.

Like a company, specializing in providing solutions for pellet production. Recently, we have successfully delivered the Russian customer to the drum granulator of limestone sxzgz-3210. Used for the production of high -quality limestone granules. This Russian client is a well -known local company for the production of building materials, specializing in the production and sale of limestone particles. Since market demand continues to grow, company needs to increase the efficiency of its production lines and product quality. Due to the demand for high performance, customers chose drum granulators between drum and disk granulators. Model SXZGZ-3210, production capacity 15-30 subject.

Our drum granulator SXZGZ-3210 has gained recognition of customers due to its excellent performance and stable working condition. It can produce limestone particles with a homogeneous particle size and high strength. Match the strict requirements of customers to product quality. The customer was very pleased with the operation of the equipment from the moment of its installation and commissioning. They especially appreciated the simplicity of operation and equipment performance. The reviews said, that new equipment helped them significantly increase productivity and product quality. Successfully satisfying the growing market needs.

Frequent questions about the drum granulator!

At fertilizer production drum granulator Suitable for the production of complex fertilizers of cold, hot and low, medium and high concentration. Hot and cold granulation process The drum granulator refers to two methods of forming granules of fertilizers under different temperature conditions. These two methods have different applications and advantages in the production process:

Drum granulator of cold granulation

Cold granulation in the production of fertilizers is a granulation process at room temperature. This method does not require the heating of the material. For the formation of particles, it is mainly based on mechanical force and binder material.

Features include:

- 1

Suitable for heat -sensitive materials: Some ingredients can decompose or lose activity at high temperatures, Therefore, cold granulation can maintain the effectiveness of these ingredients.

- 2

Energy saving: since heating is not required, Energy consumption is low.

- 3

Suitable for simple processes: usually used to produce some fertilizers, not requiring strict requirements for the size of particles or strength.

Drum granulator for thermal granulation

Thermal granulation in the production of fertilizers involves heating the material to a softened or partially molten state. Then the granules are formed using the drum -granulation mechanism.

Features of this process include:

- 1

Improved pellet quality: With thermal granulation, more rounded, dense and durable pellets. Increasing the efficiency of fertilizers.

- 2

Better suited for certain chemical reactions: Some types of fertilizers require chemical reactions at high temperatures to increase their effectiveness or stability.

- 3

Fast drying: since the granules are formed at high temperatures and the moisture content is reduced, The subsequent drying process can be reduced.

The choice between cold or hot granulation usually depends on such factors, as requirements for the final product, characteristics of raw materials and production costs. For example, In complex fertilizers (Such as nitrogen, phosphorus and potassium complex fertilizers) The process of thermal granulation is often used, to ensure the uniformity and stability of particles. Some organic fertilizers may be subjected to cold granulation to protect the activity of organic ingredients.

Speed drum granulator It is impossible to install, based exclusively on experience. You need to accurately calculate the speed, Given the three main technical factors. Then set the speed:

Characteristics of the material:

The key parameters are the angle of natural sloping of the material (defining the critical threshold of sliding and rolling in the drum) And density (influencing centrifugal force, acting on the material). Materials with a small angle of natural sloping (For example, less than 30 °) and high density require a slightly higher rotation speed (12–15 rpm) To ensure a sufficient turn of materials. Materials with a large angle of natural sloping (For example, more than 45 °) and low density should have a rotation speed of 5-8 rpm. This prevents the destruction of particles, caused by excessive mixing of the material.

The parameters of the drum design:

The diameter of the drum is inversely proportional to the speed of rotation. According to the industry technical formula, “The optimal rotation frequency = 42.3/√ Drumener of the drum (m)». For example, For the drum with diameter 2,2 m The optimal rotation frequency is approximately 42.3/√2.2.2 ≈9 rpm. For the drum with diameter 3,0 m The optimal rotation frequency is approximately 42.3/√3,0≈7.7 rpm. This formula can be used as a basic reference information to configure the speed of your drum granulator.

Requirements for finished particles:

If you need to get small particles (1-2 mm), The speed of rotation can be appropriately increased (10-12 rpm). High -frequency collision is used to stimulate the formation of small particles. To obtain large particles (3–5 mm) rotation speed should be reduced to 6-8 rpm. It is necessary to give the material enough time for agglomeration on the principle of "snow coma", to prevent particles crushing.

More information about the rotary drum granulator can be found on the site:https://www.sxmashina.com/granulyator-s-vrashchayushchimsya-barabanom/

Among the main technical parameters rotary drum granulator The angle of inclination of the drum directly determines the time of stay, flow rate and the effect of granulation of the material in the drum. This is a key link between "production efficiency" and "particle quality". If the angle of inclination is too large, the material will quickly unload, which will lead to incomplete granulation. If the angle of inclination is too small, The material will accumulate, causing clogging and reducing performance.

How to determine the angle of inclination of the eardrum, for your production needs?

The key point when designing the angle of inclination of our drum granulators is the balance between the time of the material and production efficiency. This is based on two key technical factors. Based on these two points, you can determine the angle of inclination of the drum granulator that suits you.

- The path of movement of the material inside the drum: based on principles hydromechanics. The movement of the material in a rotating drum is divided into "sliding zone", "Parabox zone" and "rolling zone". With too large angle of inclination, the material quickly gets into the sliding zone. Insufficient stay time (less 2 minutes) And insufficient granulation. With too low angle angle, the material remains in the rolling zone for a long time. This can lead to the accumulation of material and clogging. Industry technical standards usually provide an angle of inclination from 2 ° to 5 °. This is done for that, so that the material moves mainly in the parabolic zone. Allows you to balance the time of stay (3–5 minutes) With fluidity.

- Dependence of productivity on the length of the drum: With a fixed daily volume of pellet production, the angle of inclination must be adjusted depending on the length of the drum. For example, for the drum φ2.2 × 6 m with watch performance 10 tons of inclination angle of 3 ° can satisfy the requirements for the flow rate of the material. If the length of the drum is reduced to 4 m, The angle of inclination must be increased to 4 ° -4.5 °, to ensure the same performance. Increase the speed of the material. However, it is necessary at the same time adjust the speed of rotation, To avoid decreasing granulation rate.

How to make accurate adjustments?

This requires the use of professional tools when making adjustments. You can use the level to measure the difference in heights between the two ends of the video. Calculate the value of the adjustment by the formula "Height difference = roller length × tan (The angle of inclination)». For example, If the video is long 6 m must adjust to 3 °, The difference in heights between the two ends will be approximately 6 X tan3 ° ≈ 0,314 m. Accurate positioning is achieved by the addition or removal of gaskets under the support of the roller.

More information about the rotary drum granulator can be found on the site:https://www.sxmashina.com/granulyator-s-vrashchayushchimsya-barabanom/