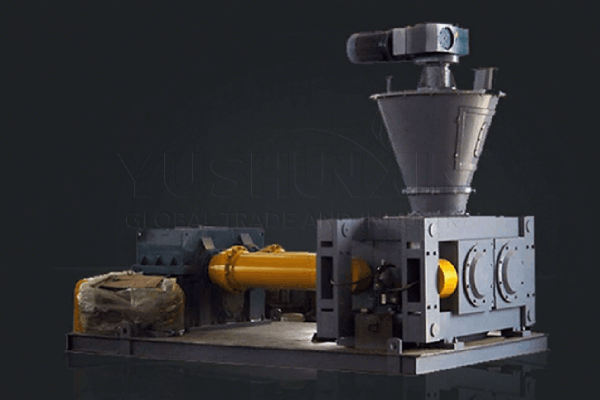

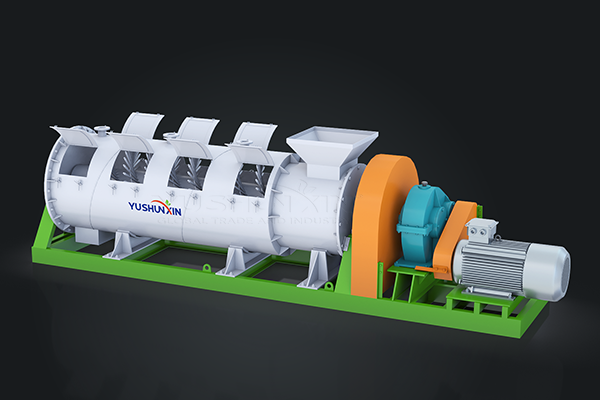

Screw extrusion granulator

- Power: 7,5 – 315 kW

- The size of the particles: 0,5 – 6 mm

- The degree of granulation: 90% +

- Production capacity: 1 – 160 subject.

- The size of the particles of raw materials before granulation: 50 oven.

- Moisture content of raw materials before granulation: 20% – 40%

- Equipment material: Carbon steel Q235, Rubber material lining

- Application: Manure animals, The remains of biogas, humus, brown coal, NPK, bentonite, Mineral fertilizers…

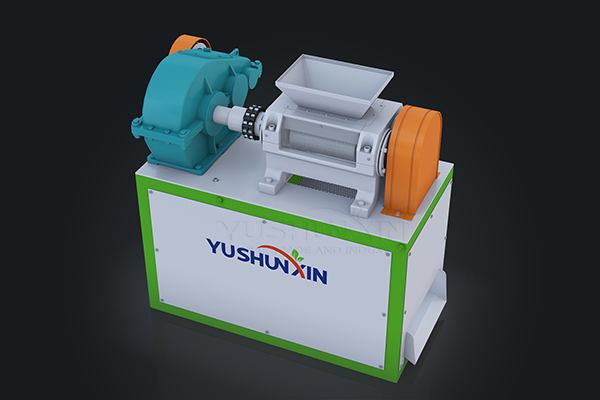

Potassium fertilizers - One of the important fertilizers, necessary for agricultural crops. For that, so that potassium fertilizers are convenient to store, Transport and use, We launch a new type of granulatory equipment - Potassium fertilizer granulator. This product is an improved product, which we specially absorbed new technologies of foreign granulators.

He presses the raw materials of potassium fertilizers into granules through physical pressure. This is granulation equipment and equipment, which are very suitable for the production of potassium fertilizers. If you are interested in investing in the industry production of potassium fertilizers or produce potassium granular fertilizers, then definitely do not miss this special equipment for granular fertilizers!

What granulation process does our granutor use potassium fertilizers, so that you can better produce high -quality granules of potassium fertilizers?

Our granulator of potassium fertilizers uses dry technology for you rolling. Under the influence of external pressure, the added materials are forced to pass through the gap between the two relatively rotating rolls and contract on pieces. In the process of rolling, the actual density of the material may increase in 1,5-3 times. To satisfy your requirements for particle strength.

Powder -shaped potassium -shaped potassium fertilizers with moisture content ≤5% in flakes or blocks can press the potassium granulator. Then it is divided into entire particles using a particle crumpling device. You just need Conduct the verification process, to choose granular potato fertilizer materials, corresponding to your requirements. During the entire granulation process, additional humidity will not be added to your materials.

As our granutor of potassium fertilizers, granular for you granular powder materials of potassium fertilizers?

Inside the granulator of potassium fertilizers there are two clamping videos with a certain gap between them, rotating in opposite directions at the same speed. On the surface of these two clamping rollers there are many grooves of a semicircular or other shape. The specific shape of the groove can be configured in accordance with the form of product particles, which you want.

When powder material of potassium fertilizers is covered in a granulat, it falls between the two rotating clamping rollers. And due to the action of gravity and a special feeding device, the material will fall evenly between two clamping rollers. As the clamping roller rotates, the material slowly “bite” into the duct groove.

It compresses when the clamping roller rotation. In the process of compression, the material is becoming denser and denser. After reaching maximum pressure, the material is compressed into flakes or blocks. Then the clamping video rotates, and the pressure is slowly reduced. When the pressure decreases to a certain level, They will fall out of the drum grooves due to their elasticity and their own weight.

The falling lumps will fall into the crushing device and divide into small particles. Then it is sifted on sifting equipment And, finally, becomes necessary for you with granular potassium fertilizer.

Is it possible to adjust the distance between two clamping rollers inside the granutor of potassium fertilizers?

Certainly, Our potassium granulator regulates the distance between two clamping rollers hydraulically. Of the two clamping rollers, one is fixed, and the other can move forward and backward. Inside the machine will be installed Hydraulic device. He presses a movable clamping video closer to a motionless video or from it. Thus, the pressure between two clamping rollers is regulated and the density of particles of potassium fertilizers is controlled.

What is the auxiliary equipment for the production of potassium fertilizers based on potassium fertilizer granutor?

Used for careful and uniform mixing raw materials.

Store mixed material.

Improve accurate control over the amount of raw materials added, to ensure the quality and stability of the product.

Provide the supply of materials for subsequent equipment with constant speed and in constant volume. Avoid product quality fluctuations, caused by unstable supply of materials.

Through physical extrusion, the material turns into particles.

Break the flakes or blocks of materials into entire granules in the granulator.

Send unqualified granules back to repeated granulation.

Compared to other fertilizer production lines, Production lines based on potassium granulators require a greater height of the site. Its production process is performed in one pass from top to bottom. Small occupied area. If you have a limited production space, Consider the possibility of installing a line for the production of potassium fertilizers!

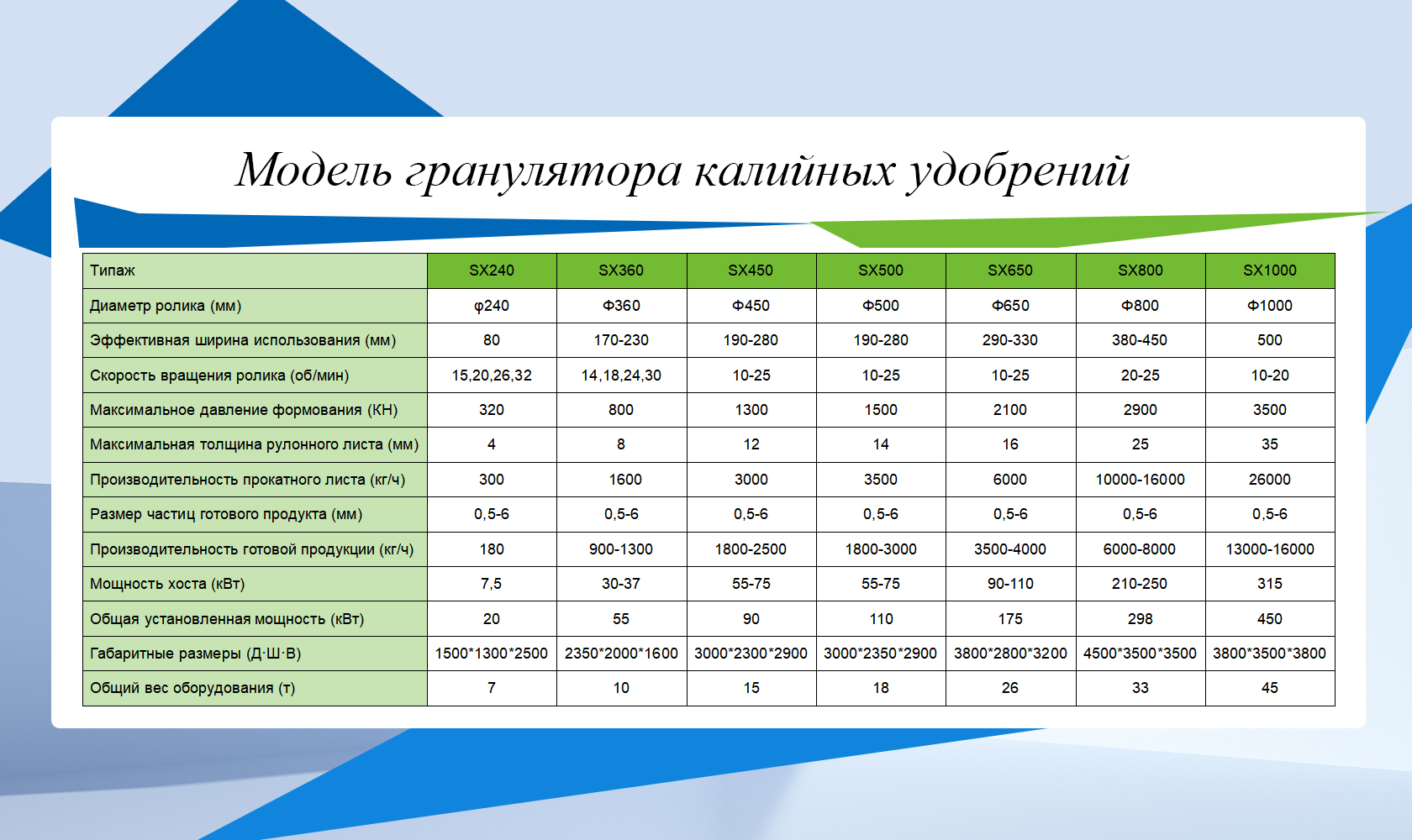

What models of potash fertilizers at our factory are available to you?

In addition to potassium fertilizers, We also have Drum granulators, Granulators "two in one" And Disk granulators for wet granulation processes. Granulator of organic fertilizers - specifically designed to gran organic fertilizers. Flat die pelletizer, Roller granulator and t. e. for the process of dry granulation. We constantly study various advanced granulation processes and develop New fertilizer granulum equipment. If you have the need for granular equipment, Please, Contact us To obtain more information!

Frequently asked questions about potassium fertilizer granulator.

Granulator of potassium fertilizers Suitable for grancing of various raw materials of potassium fertilizers. Below are some suitable materials for fertilizers and powdered materials:

File materials: potassium sulfate, potassium chloride, Russian red potassium, Complex fertilizer NPK, Ammonium chloride, nitrate potassium, Monoammonyfosphate, Diammonyphosphate, Ammonium sulfate and ammonium bicarbonate.

Powder materials: antioxidant, Bromhlorgidantoin, cyanide sodium, sodium dichlorizocyanurate, Trichlorizocyanurate sodium, Cyanurus acid, bleach, oxide zinc, lead oxide, potassium carbonate, carbonate strontium, calcium chloride, Calcium hydrophosphate, Sodium metasilicate, Sodium orthosilicate, cryolite, aluminum. extense, brake powder, rubber and plastic additives, White soot, Calcium aluminum, Heavy calcium, Ordinary calcium, carnallite, Powder of phosphorite ore, Metal powder, fillers, Feed additives, Adicloprid, nicotinic acid, Nicotinamide, Pharmaceutical intermediate products, auxiliary means for smelting steel, Snowmaking agents, environmentally friendly materials, etc..

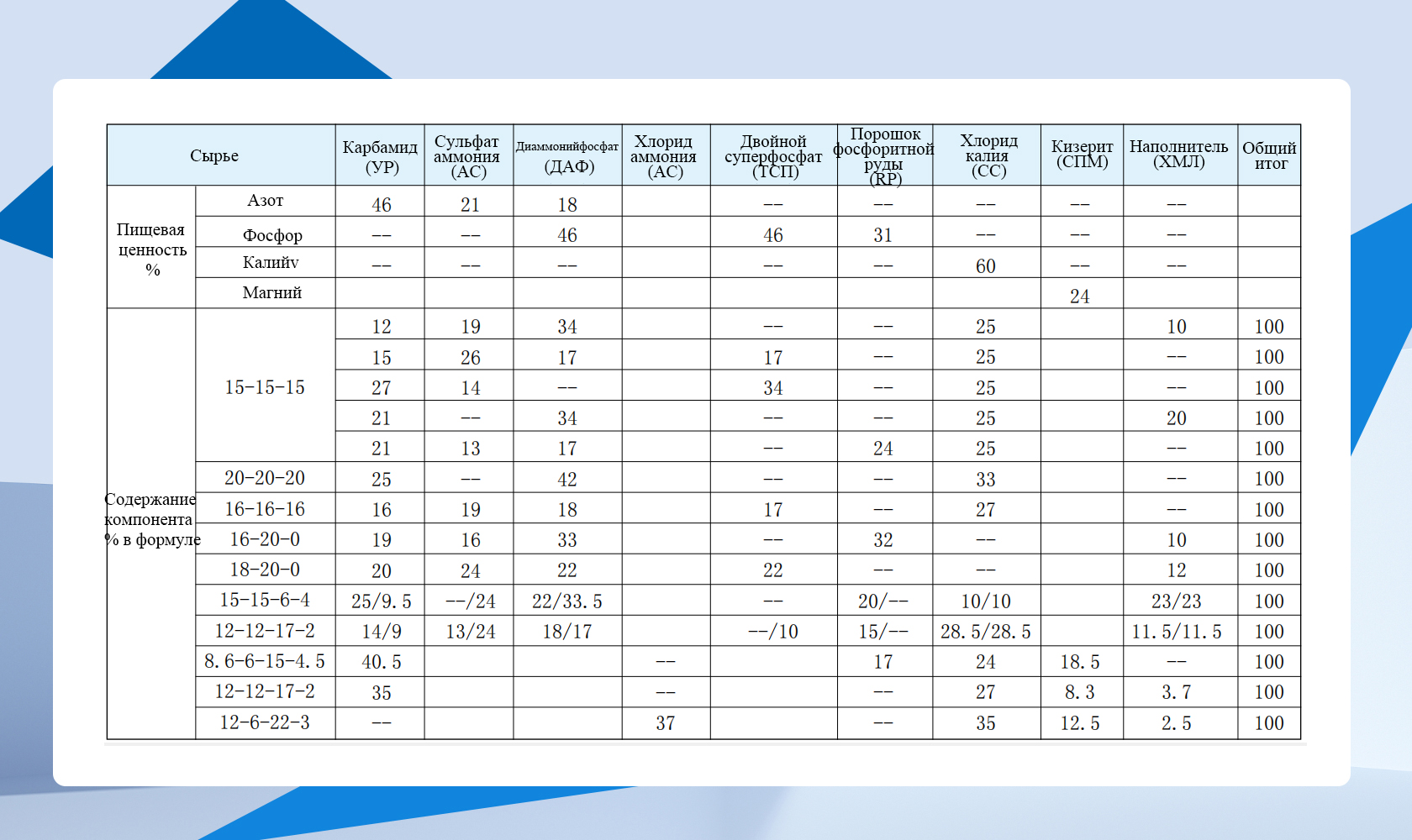

You can produce various types of potassium fertilizers through a granutor of potassium fertilizers according to your recipe.