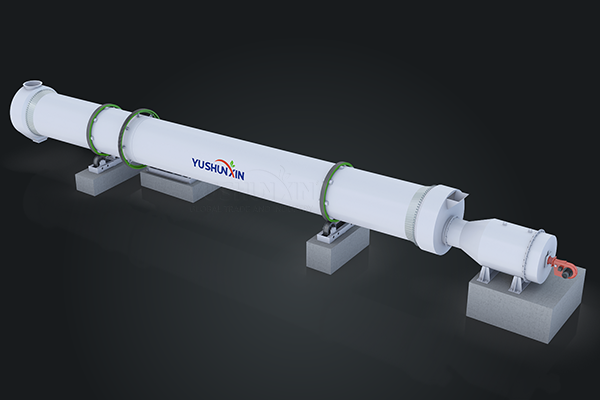

Rotor dryer

- Production capacity: 1~18 (subject)

- Type of equipment: Drying

- Applicable materials: Organic fertilizers/slag/limestone/coal for power plants, etc.. e.

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from manufacturers: Yes

In the process of production of granular fertilizer after the completion of granulation, granular fertilizer must be dried, to remove excess water. At this time you need to use a dryer, To dry it. Rotary drum drying machine, produced by our company, It is mainly used for drying bulk materials within a certain range of humidity and particle size and is widely used in the production of combined fertilizers, production of organic fertilizers and t. e. In accordance with the requirements of various industries to the content of moisture in the dried materials, moisture content in materials, dried with our drum dryer, can reach less 1%-0,5% for you.

Our rotary dryer mainly consists of a rotating case, partitions, transmitting device, supporting device and other components. Reasonable layout, high efficiency and energy saving. It has strong adaptability to materials. He can not only dry granular materials for you, but also dry some sticky pasty materials or materials with a high water content. Its advantages are a large drying container, A wide range of application, ease of operation, high efficiency of drying and small stream resistance.

Roting dryers are usually used with rotational cooler, And we will introduce you rotation cooler later.

How our rotary dryer works for you?

Finished granular fertilizer in The band conveyor or bucket elevator He goes to the bunker, and then through the supply pipe enters the boot end. The slope of the supply pipe should be greater than the natural inclination of the material, so that the material can smoothly enter the dryer.

When installing for you, we deliberately tilted the dryer drum at a slight angle to the horizontal. The material is submitted from the upper end, And the coolant arrives from the lower end and contacts the material in the anti -flow. (Of course, The coolant and material also flow into the cylinder together.) When the drying cylinder is rotated, the material moves to the lower end under the influence of gravity. When your wet material moves forward in a barrel, He directly or indirectly receives heat from the coolant, So wet material is dried, and then sent at the unloading end through the strip conveyor or a screw conveyor. At this time, the moisture content of the resulting material will fall approximately to 1%.

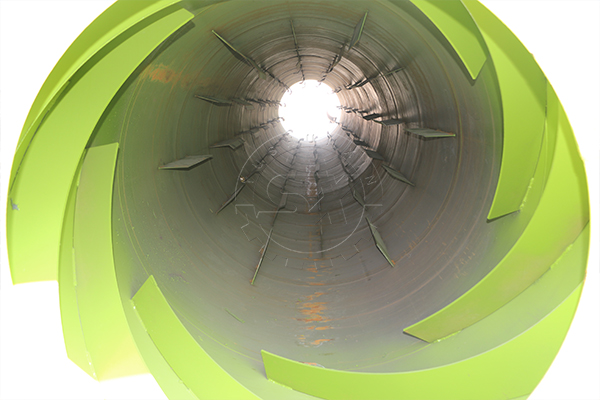

We also installed for you the casting of plates on the inner wall of the rotary dryer. Its function is, to raise materials and scatter them, to increase the surface of the contact of materials and air flow, To improve drying speed and accelerate the promotion of materials. Reduce time, Sent to dry materials, and increase your performance.

What different types of drying can our rotor dryers offer you?

Our drum dryers have two drying classifications, which correspond to two different types of drum dryers: direct -flow rotor dryer and anti -flow rotor dryer.

Direct rotor dryer means, that in the dryer the air flow and the material move in one direction, That is, they come from one end. Anti -flow rotor dryer means, that in the dryer the air flow and the material move in the opposite direction, That is, the material enters from the upper end, And the air flow enters from the lower end.

Both drying methods have their pros and cons of. The choice of drying method is determined by the nature of your material and moisture content, which is required by the product. If you do not know, Which drying method to choose, You can tell us your raw materials, and we will select a suitable drying method for you in accordance with your raw materials.

How our rotary dryers will help you save fuel?

Our rotor dryers use high -temperature stoves for you with a pseudo -rigged layer. It has a strong applicability to coal types and can use Bitumine coal or anthracite, as well as low -quality coal and slag. It can achieve the effectiveness of combustion more 95% for you. And the temperature is uniform, And the supply of heat is stable. Our rotary dryer can increase your performance by 50%-80%. Saving costs and increasing profits for you, He also protects the environment.

How our rotor dryer eliminates you for you the phenomenon of "aerotherapy" in the drying process?

Our company has introduced many technical innovations into the dryer lifting devices system and has applied a combined lifting device for you in a rotary dryer design. The organic combination of the angular lifting plate and the rotary lifting plate makes the exchange of materials and hot smoke gases more efficient. This reduces the probability "Aerodynamic pipe»In a dryer and overcomes the phenomenon of an" aerodynamic pipe ", characteristic of traditional dryers.

Why do we recommend that you buy our drum dryer?

You can be sure, What will you choose us, because our drum dryer has many advantages:

Our drying machine has a high thermal effectivelyb and a significant effect of energy conservation. After testing, thermal efficiency significantly exceeds the level of traditional dryers with one cylinder approximately 50%. After that, how equipment is launched into production, The effect of coal saving is very obvious.

The length of our drum dryer is reduced, which positively affects the technological scheme. The length of the entire car is about 40% Briefly speaking, than a single -cylinder dryer. Thus, The development area of your plant is reduced, Engineering investment is saved and is more suitable for your process of transforming an old factory.

The area of the outer surface of the machine is reduced by more than 30% Compared to a single -cylinder rotary dryer. And insulating cotton wool is installed in the middle for you, So the external cylinder has the effect of thermal insulation on the inner cylinder. The surface temperature of the outer cylinder is low, And thermal losses are small. Effective and energy -saving, It significantly improves your working environment and working conditions.