Recently we received an email from Latvia. The email said, that they are a manufacturer of organic fertilizers based on chicken droppings and want to replace part of production equipment. They want, so that we present the equipment our factory along the line for the production of chicken in Latvia, Paying special attention to the equipment for granular and equipment for drying. Upon learning, that their daily consumption of chicken droppings is about 260 ton, Humidity is 90%-92%. Several of our engineers held an hour's meeting, to discuss a suitable decision. After that, how it was provided to customers, He was well accepted by customers.

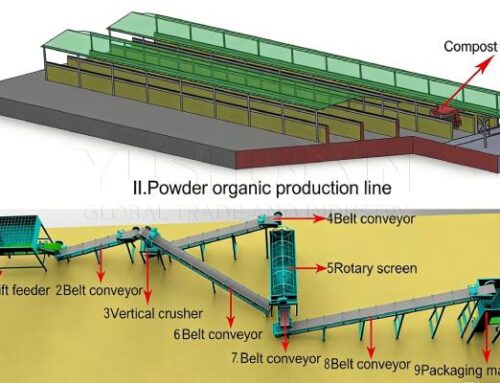

Composting equipment.

Due to the large daily processing at the plant, we recommended some equipment for composting, which will help increase production efficiency.

Compared to traditional equipment for composting, The rover of the wheel compost made a new breakthrough in the turn of turning. Maximum width, which we produce, can reach 15 m, and a specific width should be configured in accordance with the client’s situation. The depth of the rotation of materials can achieve 3 m. Due to the large daily volume of processing at the plant, we offer, to, If he selects a lathe for roulette, He could choose a machine gun for a double roulette. Increase performance and speed. The price of the device is usually from 150 000 to 200 000 (Yuan).

The daily performance of this composter is also relatively great. We offer, so that the plant builds several more fermentation tanks, To fully use the equipment function "One machine with several slots". Besides, This type of turning equipment is equipped with a complete set of auxiliary equipment (For example, system of spraying, automatic distribution system bacteria) with a higher degree of automation and high processing performance. This is very suitable for the situation in this factory.

Granulation equipment.

This granulator is suitable for granular chicken droppings, The entire granulation process takes 3-5 minutes, and the degree of granulation is about 97%. The proportion of large particles is less 10%, and the size of the finished particles is mainly less 0,3-3 mm. This granulation equipment requires, so that the size of the material of the material before granulation is less 200 oven. The content of organic substances in the pellets produced is 100%.

The advantage of the disc granulator is, that he can see the granulation situation, which is convenient for timely adjustment. The degree of granulation exceeds 93%, and the size of the granulation particles is from 1 to 8 mm. The disk granulator requires, so that the diameter of raw materials is about 50 oven. The manufacturing process takes 5-8 minutes.

Both devices are available in various models, Moreover, different models have different production capacity. After that, as the manufacturer decides, what kind of granulation equipment to use, He selects the model in accordance with a specific situation.

Drying equipment.

Our dryer drum is a whole spiral pipe thick 10 mm, which has such advantages, As a high concentricity, Strong steel and stable work. The lifting plate is 5 mm. Choose reasonable working parameters for you, To balance "coal, Material and air ", thereby significantly improved thermal Efficiency dryers and reducing the consumption of energy for drying more than 30-50%.

There are many types of dryers with varying degrees of drying. We offer the manufacturer to choose a dryer SXHG-2424 model, processing performance can reach 14-18t/h.