Organic fertilizer fermentation pot

- Performance: 5m³-150m³ (You can configure).

- Price: 17,865 $ (100m³).

- Raw materials: Pig manure, Chicken manure, Cow navis, Sheep manure, The remains of fungi, The remains of traditional Chinese medicine, straw and other organic waste….

- Scope: Tribal industry, Circular agriculture, Ecological agriculture.

- Advantages: Automatic aeration management, temperature control, mixing and deodorage. Small occupied area. Equipment is resistant to corrosion…..

Enzyme for organic fertilizers became important equipment for the processing and transformation of organic waste. It is designed to optimize the fermentation process. Our enzymatic tanks for organic fertilizers are equipped with modern aeration control systems, temperature control, mixing and deodorage. Significantly increase the efficiency of fermentation and the quality of fertilizers. The equipment occupies a small area and is suitable for farms of any size.

It is made of corrosion -resistant materials, which ensures the durability and durability of use. Suitable for a wide range of raw materials. Including pork manure, Chicken manure, Cow navis, Sheep manure, The remains of fungi, The remains of traditional Chinese medicine, straw and other organic waste. Equipment with a capacity 100 cubic meters costs approximately $17 000. Welcome, Contact us, To purchase and help you achieve effective and environmentally friendly agricultural goals.

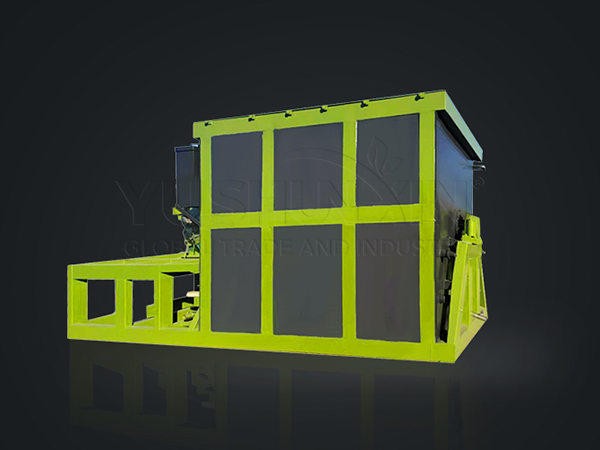

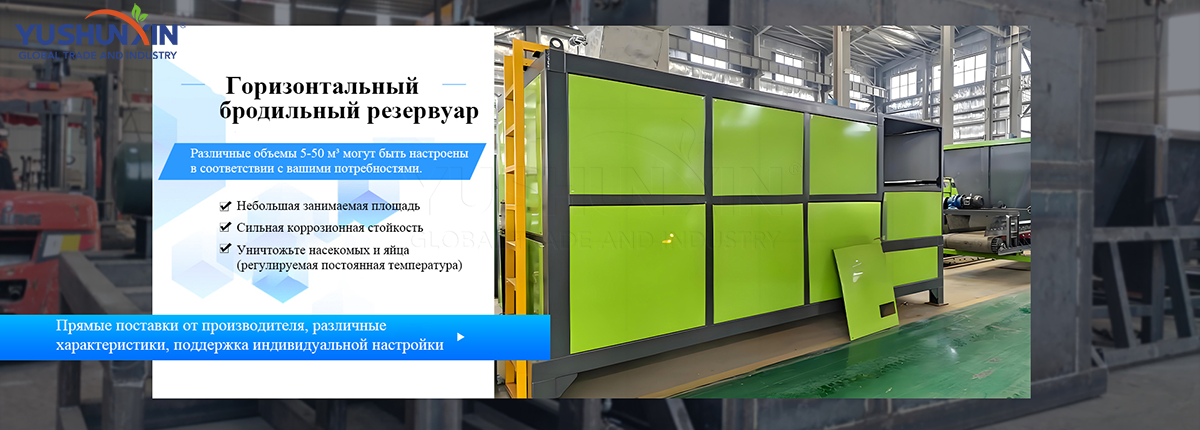

Horizontal enzyme reservoir / Vertical enzyme reservoir

Horizontal fermentation reservoirs and vertical fermentation reservoirs are two common equipment for fermentation. Horizontal fermentation tanks are usually used to process solid organic waste, such as cattle and bird manure, straw agricultural crops and t. e. Vertical enzymes are used in the production of fertilizers for liquid organic waste or there, where high space savings are required.

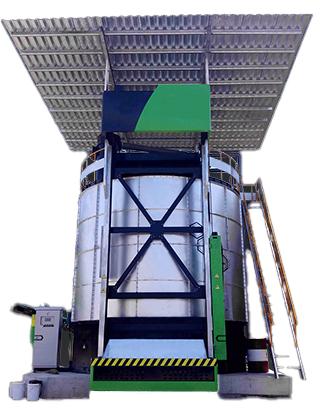

Vertical enzyme reservoir

Vertical constructions of tanks are usually higher and take up less space. Choose it, If your production space is limited. Will help you achieve greater productivity in limited space. Due to their vertical design, vertical enzymes use gravity better to facilitate the movement of the material. Thereby improving the efficiency of enzyme. All our vertical enzymes are equipped with heating systems. To guarantee, that you can control the temperature during production. Designed taking into account cleanliness. Our fermentation vats can perform CIP (Cleaning in place, Cleaning in place) outo Sip (Sterilization in place, Sterilization in place).

Vertical enzyme reservoir

Horizontal enzymes are longer, lie evenly and usually occupy a large area. The horizontal design makes the contact area with the material relatively large, which facilitates the mixing of materials and gas exchange. This is useful for transmitting oxygen and warming heat during fermentation. At the same time, we have developed a built -in temperature control system for you, which will help you maintain a suitable fermentation temperature. Our horizontal enzyme can have various performance. To accommodate small -scale or large -scale production. The horizontal structure is also easier to serve and clean in the future.

The corresponding designs of two enzymers make them suitable for various fermentation processes. For example, horizontal enzyme can be more suitable for processes, not requiring intensive mixing. Vertical enzymes are suitable for liquid fermentation processes, requiring intensive mixing and temperature control. The choice of the type of enzyme usually depends on the characteristics of the enzyme process, capacity, accessible space and economic reasons.

The corresponding designs of two enzymers make them suitable for various fermentation processes. For example, horizontal enzyme can be more suitable for processes, not requiring intensive mixing. Vertical enzymes are suitable for liquid fermentation processes, requiring intensive mixing and temperature control. The choice of the type of enzyme usually depends on the characteristics of the enzyme process, capacity, accessible space and economic reasons.

What are the advantages of our enzyme tank for organic fertilizers?

Our organic mineral fertilizer uses for you the technology of high -temperature fermentation of aerobic bacteria, which reduces the time of processing of manure and garbage and reduces operating costs. The design of multi -layer aeration provides a sufficient amount of oxygen and good breathability, which allows you to fully activate the activities of aerobic bacteria and accelerate the process of fermentation for you. The whole process is automated as much as possible and easy to operate. This is the best choice for your transferred manure.

Our reservoir for fermentation of organic fertilizers solves for you the problem of a long time to enzyme traditional compost. We added for you the thermal conductivity system to the tank body. After that, How do you add special Enzymatic strains For an enzymatic reservoir, He can ferment and decompose the material for you during 48 hours. Moreover, Fermented organic fertilizer may comply with the standard of harmlessness, and throughout the process there are no wastewater or waste discharge.

How can you use our enzyme for organic fertilizers, so that he does work on enzyme for you?

Our enzyme organic fertilizer can be controlled by one person. A high degree of automation can perform automatic supply for you, Automatic temperature control, automatic mixing and automatic unloading. The workflow is also very simple and clear.

Firstly, You need to transport the material to the enzymatic reservoir through The band conveyor, and then add a certain amount of monocolation for fermentation. Then you need to start the heating device and the mixing device, to monitor and the material mix evenly. You should know, that a wet and hot environment in an enzyme can provide a good place to reproduce the added strains, and the rapid reproduction of strains will also accelerate the decomposition of the substance.

In accordance with the characteristic requirements of various strains, when the temperature of the material rises to a certain temperature, You need to open a ventilation device, so that it saturates with oxygen enzymes. Built -in rotating blades of the enzyme of organic fertilizers will mix the material, to reduce its temperature, thereby providing a stable habitat for the propagation of bacteria. When the fermentation cycle is reached, You can open the unloading hole, To unload the material from the unloading hole. At this time, unloaded material is a high -quality organic fertilizer, which you need.

How our reservoir for fermentation of organic fertilizers unloads materials for you?

Different materials have different unloading methods. Our fermentation tanks for organic fertilizers are suitable for various types of materials. It also significantly increased production efficiency and product quality thanks to advanced technical means. Make your production process more efficient, economical and safe. Regardless of your specific needs. We can all offer an individual solution, Respecting your needs.

Powder material unloading plan

For powdered materials, we use pneumatic shutters. This design has the following significant advantages:

- High speed of unloading: The pneumatic system can open quickly and close, allowing the material to flow quickly. Increased unloading efficiency.

- No residues: Accurate pneumatic control provides a complete unloading of materials. This avoids typical problems with the remnants, arising with traditional methods of unloading. The amount of waste is reduced and the cost of cleaning is reduced.

- High reliability: The pneumatic structure has fewer mechanical parts and a low level of failure. Reduces your needs for service and downtime.

Solutions for unloading highly dispersed or semi -liquid materials

For highly dispersed materials or semi -liquid materials, we offer two options: Hand Throthel valve and pneumatic throttle valve:

- Manual throttle valve: This design is suitable for cases, when flexible stream control is required. Easy to operate and durable, It is suitable for various working conditions.

- Pneumatic throttle valve: Compared to the manual throttle valve, the pneumatic throttle valve can automatically control. No manual intervention is required, and it is suitable for large -scale continuous production. Efficiency and consistency are even more improved.

What performance can our enzyme for organic fertilizers cope with you?

We can configure tanks for the fermentation of organic fertilizers of various containers from 5 to 150 m³ in accordance with your needs, To satisfy your various performance requirements. Besides, We also have two different types of enzyme, Horizontal and vertical, On your choice. If you do not know, How to choose, You can tell us the type of raw materials and other information, And we will give you some tips.

How much workplace do you need for our enzyme organic fertilizer?

Our reservoir for the fermentation of organic fertilizers is occupied by an area of about 10-30 square meters. Different types of fermentation tanks have different sizes. Therefore, the specific area of the floor depends on that, what type of tank for fermentation of organic fertilizers do you choose.

What are the advantages of using containers for organic mineral fertilizer for your fermentation process?

Our enzyme for organic fertilizers uses closed fermentation for you, which can ensure deodorage on 99%. Using an automatic temperature control system, you can adjust the temperature to a high temperature of 80-110 ° C, to completely kill the eggs of diseases and insects. The enzyme has an excellent heat conservation function, and is not limited by the cold season, And it can work normally for you even in minus 20 Grades of heat.

Besides, Our reservoir for fermentation of organic fertilizers is made for you with a three -layer structure. Good mechanical material, which can solve the problem of strong acid and strong alkaline corrosion, And the service life can reach more 10 years. The insulation layer inside the tank is made of polyurethane, This material will not be influenced by the outside world and will be able to provide you with normal fermentation throughout the year. The tank control system for fermentation uses for you an automatic and manual chip control system PLC, which is convenient for you in operation and management.

The guide to choose a fermentation tank for organic fertilizers will help you choose a high -quality enzymatic cylinder!

The choice of the correct enzyme of organic fertilizers is crucial to ensure the effective production of fertilizers. This not only helps to increase production efficiency, but also improves the quality of the final product. When choosing a container for fermentation of organic fertilizers, the following factors should be taken into account. To find the most suitable fermentation reservoir.

- Productive processing: Select an enzymatic reservoir with the corresponding characteristics, Based on the requirements for the performance of daily or periodic processing.

- The quality of the material: In high -quality fermentation containers, corrosion -resistant and heat -resistant materials should be used. For example, stainless steel or special alloy.

- The degree of automation: Choose equipment with a full automatic control system. To improve the convenience of work and the effect of enzyme.

- After -sales service: Consider after -sales maintenance and technical support, provided by the manufacturer. Provide long -term stable equipment.

When you use an enzyme for organic fertilizers, What should you pay attention to?

When you use our reservoir to ferment organic fertilizers, It is necessary to pay attention to many points, such as pressure inside the tank, Ways to sterilize the filter and t. e. These precautions will be sent to you along with the operating manual of the enzyme, When we send you the product. Certainly, If you don't understand anything, You can also contact our customer support service, They are professional.

| Type | SHFJG-5 | SHFJG-10 | SHFJG-20 | SHFJG-90 |

| Heating power (kW) | 4*6 | 4*6 | 8*6 | 46 |

| Mixing power (kW) | 7.5 | 11 | 18.6 | 26.6 |

| Reducer model | Bled74-289-7.8 | Bled85-439-11 | BLED95-391-18.5 | Xwd4-29-3-4 |

| Mixing speed (rpm) | 3 | 3 | 3 | 8-10 |

| Dimensional dimensions (mm) | 2200*2200*5300 | 2400*2400*6900 | 3700*3700*8500 | 5000*5000*10000 |

We support the settings and we can configure enzyme in accordance with your needs.

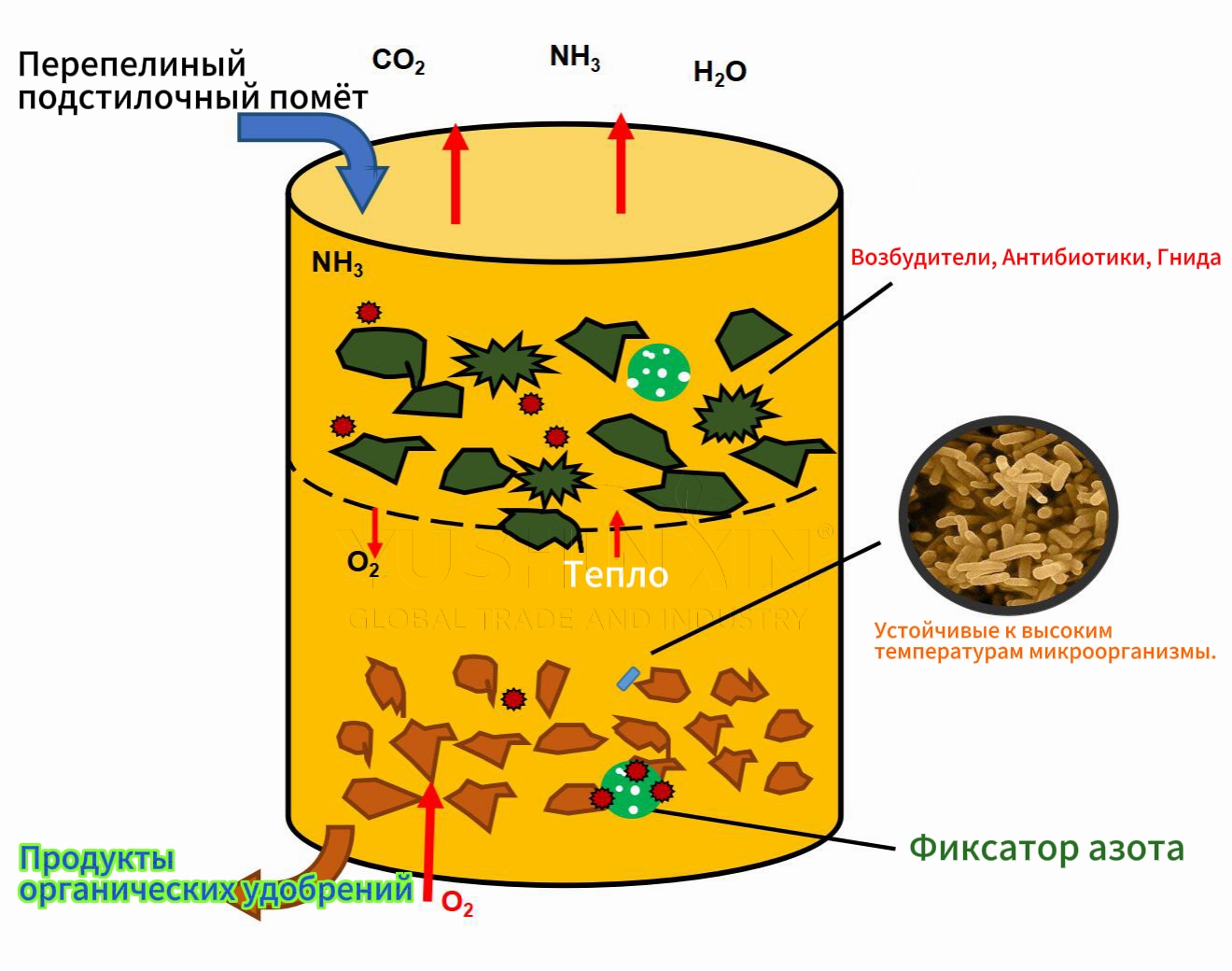

Bucky for fermentation of organic fertilizers will help you effectively process a quail bedding!

We produce for you advanced fermentation vats for organic fertilizers. These fermentation tanks are not only very resistant to strong corrosion activity of quail bedding. It is also equipped with an accurate temperature control system, effective mixing equipment and optimized ventilation scheme. Provides effective aerobic fermentation of quail littering in the controlled environment.

Harmful pathogens and parasite eggs in a quail litter, Processed aerobic fermentation, Effectively destroyed. Organic substances are stabilized, and fertilizer efficiency increases significantly. We promise to provide you with a full range of technical support and services. The guarantee of that, that you can achieve effective and stable processing of quail bedding in a wide range of operating conditions.