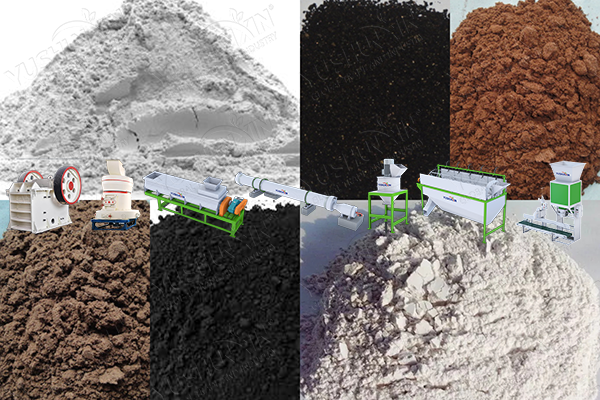

Powder mineral fertilizer - This is fertilizer, The composition of which includes minerals as the main raw material. It has the shape of a powder and can be introduced directly into the soil. To improve soil fertility and provide nutrients, necessary for plant growth. This type of fertilizer may contain a wide variety of nutrients, usually containing macro elements (Such as nitrogen, phosphorus, potassium) and / or Microelements (Such as iron, zinc, copper, Manganese and t. e in.), necessary for plant growth. Powdered mineral fertilizers are a type of fertilizer, widely used in modern agriculture. Its advantage is the rapid replenishment of nutrients, necessary for plants, in a short period of time and improving the yield and quality of the crop.

If you are interested in investing in Fertilizer production line, Fitty mineral fertilizer - a good choice for you. Its production process is simple, And investment costs are much lower, than other production lines. Moreover, The payback is fast, And you can produce many types of fertilizers. If you want to expand in the future production of granular fertilizers, you just need to purchase additional equipment!

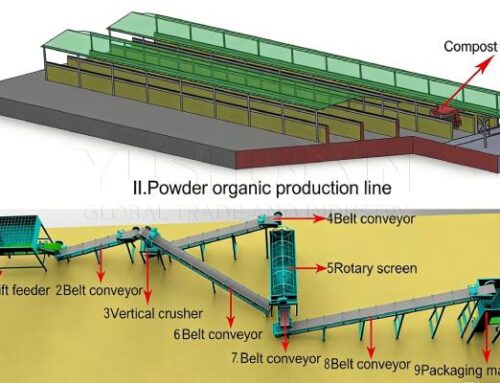

What production processes do you need on the line for the production of powdered mineral fertilizers?

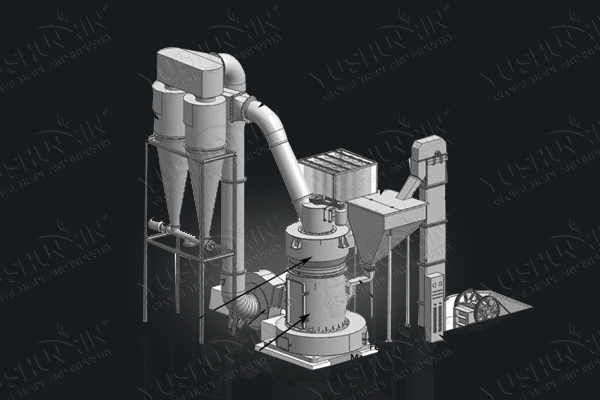

Firstly, This is the processing of raw materials. You need to crush, Grind and sort the resulting ore raw material. You can complete this process using Mills Raymond. Raymond mill is a grinding equipment, And the internal analyzer can check the crushed ore powder. One device can satisfy all your needs.

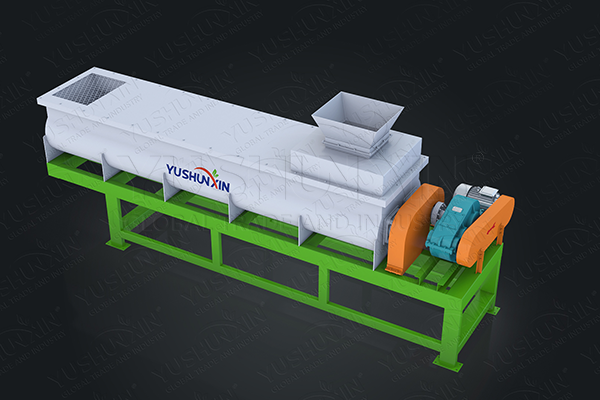

After the chemical processing process, you will need a mixer, To evenly mix the materials. Make sure, that nutrients in fertilizer are distributed evenly. Twarge horizontal mixer can work continuously and mix large volumes. High efficiency and very uniform mixing effect.

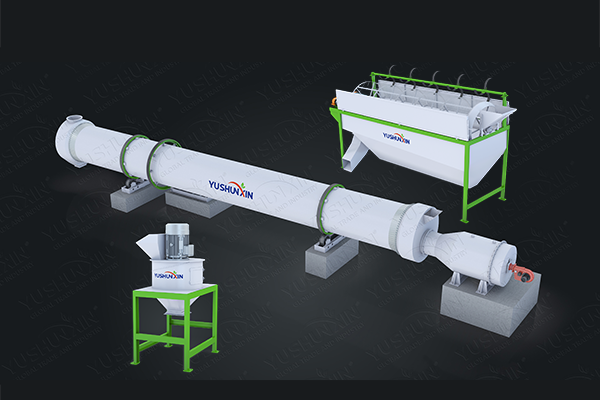

Drying, crushing And sorting are also obligatory processes. The fertile mixture must be dried, to remove excess moisture. There will be many lumpy substances in dried fertilizer, which must be chopped into powder. Chopped powder must be sifted, To guarantee the quality of the product you manufacture.

The last process - package. Packaging is required for you, If you sell it. Only well -packed products will be easier to transport, Sell and use. Your packaging should indicate the product information, including ingredients, dosage, production party and t. e. Only then will people be able to buy and use it with confidence.

If you want to produce high -quality powder mineral fertilizer, How many crushing processes are needed?

Among our many past customers there are many manufacturers of high -quality powder mineral fertilizers. To improve the quality of fertilizers, They use three crushing processes. The first step is large grinding of ore raw materials. Then it is secondly crushed on the equipment for thin grinding, such as Raymond mill, To obtain particles of smaller size. Final grinding is carried out after drying. The dried material will look agglomered. To improve the quality and product type of product, dried fertilizer is chopped again. After the process described above, the obtained mineral fertilizer has higher quality and greater popularity on the market.

If you also want to produce high quality powdered mineral fertilizers, you can use the above grinding process. Or contact us for an individual production plan. We have rich reserves of knowledge and professional engineers. We can develop a production plan, which is best suited to you.