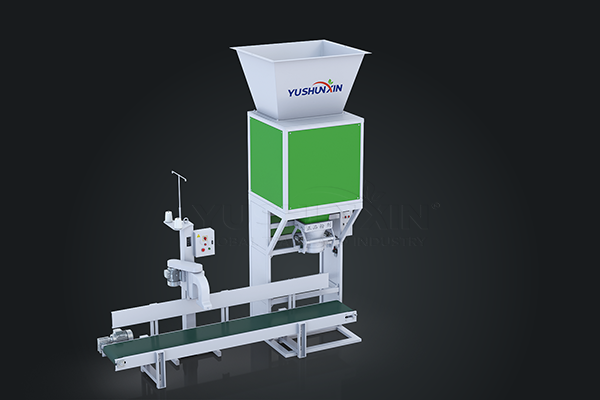

Automatic packing scale

- Production capacity: Setup

- Type of equipment: Auxiliary equipment

- Applicable materials: Organic fertilizers, Complex fertilizers, NPK fertilizers, Complex fertilizer

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from the manufacturer: Yes

Automatic packing scale called fully automatic packaging machines. It mainly consists of an automatic packaging machine, automatic equipment for weighing bags, Faltsia machine, vertical conveyor for bags and PLC for you. The whole process does not require manual control, All PLC is controlled with a pre -developed program, and the system also has a function of automatic detection and correction of errors. Compared to semi -automatic packaging weights, which require manual packaging, They allow you to effectively avoid the waste of packaging materials.

The main functions of automatic packaging weights can be conditionally reduced to two points: 1. Automatic quantitative 2. Packing and sealing. However, due to the complex use of materials and packaging, In addition to the two above basic functions, Our automatic packaging scales also have the following functions: Automatic coding, Automatic marking, Automatic package folding and other additional functions.

It is mainly used for packing bulk materials. Many materials, sold in bags, Such as Fig, Flour and fertilizer, can be packed using this equipment. This can save your labor costs and increase production efficiency. Together with Automatic stacker An automatic packaging system forms on the pallets.

Why do you need fully automatic packaging scales?

When you need packaging materials to achieve a certain performance, And the semi -automatic packaging machine requires a lot of work, And the rate of packaging cannot satisfy you at all, You need to think about choosing fully automatic packaging weights. And over time, it is inevitable to use fully automatic packaging weights to replace semi -automatic packaging machines or manual weighing and packaging.

How our fully automatic packaging scales complete the packaging process for you?

Our fully automatic packaging scales are controlled by PLC throughout the process, And design with a touch screen provides data management and the interaction of a person and machine. So specifically, How he does this process for you?

First of all, Automatic packaging machine in our automatic packaging weights will complete the suction process for you, Sorting, opening and loading empty packaging packages. When detected, that an empty packaging bag is in place in the unloading port, Automatic equipment for weighing and packaging weighs in accordance with a pre -given specification weight and puts it in a bag, To complete the automatic process of weighing and packaging for you. The machine for the formation of the jaw will help you send a filled packaging package to a device for licking the seams and will cooperate with continuous rotation conveyor tape, To complete the sealing and automatically break the thread for you.

At this stage, the material is packed and becomes a qualified product, And you can sell it.

What types of our automatic packaging weights are available for your choice?

We offer two types of our automatic packaging weights: Single -bucket automatic packaging scales and two -ox automatic packaging scales for your choice.

Both packaging weights have their advantages, How to choose automatic packaging scales? It depends on the materials used and other factors.

Single -bonded automatic packaging scales

Single -bonded automatic packaging scales

A single -bucket packaging machine for granules is designed to move in accordance with the actual needs, What is convenient for open air. It is mainly suitable for quantitative packaging of granular and small granular bulk materials with good fluidity.

Two -toch automatic packaging scales

Two -toch automatic packaging scales

The so -called two -toes automatic packaging scales mean, that the scales for quantitative packaging have two such measured buckets, who do not interfere with each other and can be weighed and unloaded in an orderly way. Two -toch automatic packaging scales are mainly designed to increase the packaging speed. Usually the efficiency of packaging of weights with two buckets is twice as high as, than the scales with one bucket.

What are the advantages of our fully automatic packaging weights, which can attract your attention?

The equipment works for you in digital format. Thanks to the full program of automatic detection and correction of errors, it can automatically determine the place of malfunction and apply alarm, that you are convenient for quick and accurate repair. The components of a completely pneumatic drive work for you, The entire workflow is environmentally friendly and safe for the environment, and the bag is completely sealed on the exhaust opening, Without forming dust. Able to serve you for a long time, For packaging with defective firmware, you can return to secondary firmware.

What should be paid attention to, When choosing to buy fully automatic packaging scales?

There are many factors, which should be considered when buying a product, especially for large equipment, such as automatic packaging scales, There are many more things, which should be taken into account. Below we have collected those factors for you, which must be taken into account when buying fully automatic packaging weights.

First of all, it is necessary to clarify the characteristics of the packaging material, which will determine the material and process of the surface of the contact of the packaging machine with the material. Secondly, Are there other requirements for weighing and packaging materials, such as the detection of the metal of the material, Cleaning with a vacuum cleaner, Dust removal, Detection and rejection of the accuracy of packaging and t. e. If you have a large production volume, You need to think about buying several fully automatic packaging weights.

Our fully automatic packaging scales are universal for you?

All in all, He is not universal. Why? Let me make a long story short and tell you carefully.

Good automatic scales for quantitative packaging have two key factors: 1. Speed. 2. Accuracy. In addition to two key factors, There are several more points, which is worth paying attention to. Firstly, This is material. Since different materials have different size, fluidity, Water content, Castle density, The angle of natural slope, temperature, etc.. e. Then there is a site factor. This will affect the packaging speed. These factors must be considered together, to have an approximate idea of that, which packaging scale to choose.

If the supplier does not ask his customers these questions, then I can safely say, that he is unprofessional. Because, as a qualified professional packaging manufacturer, It is necessary to be familiar with the influence of these factors on the packaging scales.

That's why, If you need automatic packaging machines and packaging scales, You can talk in more detail with our sales engineers. After that, How you have a preliminary choice and plan, You can take a closer look and choose the most suitable packaging machine for you.

You can contact us any time below.