INagriculture and livestock. Fykali disposal is always an important and difficult problem. Traditional purification methods are not only ineffective, but can also cause serious environmental pollution. With the popularity of the concept of sustainable development. Aerobic enzymatic tanks attract more and more attention as key equipment for the processing of manure and production of organic fertilizers. As a professional manufacturer of equipment for the production of fertilizers. Aerobe enzyme, which we provide, can turn your manure into valuable organic fertilizer. Help you with environmentally friendly production.

Why a mobile composter is the best choice for you composting on a small scale?

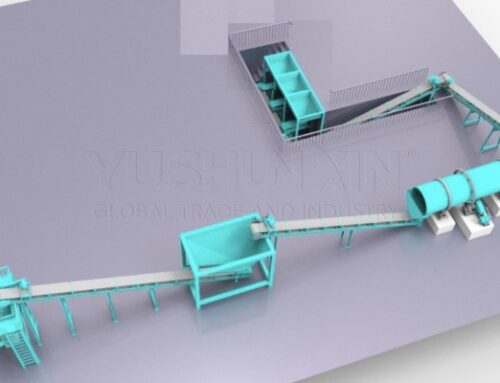

Tanks for aerobic fermentation Specially designed for bioference of organic waste (such as droplings and birds) in controlled conditions. Equipment, which is ultimately processed into organic fertilizers. Aerobic fermentation proceeds under conditions of a sufficient amount of oxygen. This is the main difference from anaerobic fermentation (without oxygen or in conditions with a low oxygen content). We can provide you with two types of aerobic enzymatic reservoirs: Vertical and horizontal.

Vertical constructions of tanks are usually higher and take up less space. Choose it, If your production space is limited. Due to their vertical design, vertical enzymes use gravity better to facilitate the movement of the material. Thereby improving the efficiency of enzyme.

Vertical constructions of tanks are usually higher and take up less space. Choose it, If your production space is limited. Due to their vertical design, vertical enzymes use gravity better to facilitate the movement of the material. Thereby improving the efficiency of enzyme.

Horizontal enzymes are longer, lie evenly and usually occupy a large area. Suitable for your large -scale production. Horizontal design facilitates the mixing of materials and gas exchange. It will also be easier for you to perform subsequent maintenance and cleaning.

Horizontal enzymes are longer, lie evenly and usually occupy a large area. Suitable for your large -scale production. Horizontal design facilitates the mixing of materials and gas exchange. It will also be easier for you to perform subsequent maintenance and cleaning.

How aerobic enzyme helps you process manure and turn it into organic fertilizer?

90 CUBLE BRODIL TANVATE

The principle of operation of the aerobic enzyme reservoir is mainly based on the process of microbial decomposition in controlled conditions. Initially, the built -in heating system regulates the temperature in the enzyme to the perfect range. Usually at 50-65 Celsius degrees. This helps to increase metabolic activity Microorganisms In an enzyme. To ensure uniform fermentation of the material and prevent the creation of anaerobic zones, the contents of the enzyme is regularly mixed with the mixing mechanism. Besides, The forced ventilation system will continuously supply oxygen to the fermentation tank. Provide the aerobic environment, microbes necessary.

During this process, the moisture control system in the installation controls and regulates internal humidity. To optimize the conditions of microbes and temperature control during fermentation. After the fermentation process is completed, the exhaust system of the fermentation tank is responsible for the safe Removal of carbon dioxide and other by -products and collecting enzymatic broth. You can use this enzymatic broth for irrigation or additionally process it into organic liquid fertilizer. Tanks for aerobic fermentation will help you achieve efficient production of organic fertilizers.

What are the advantages of buying and using an aerobic enzyme reservoir for your fertilizer business business?

The use of a tank for aerobic fermentation can significantly increase the efficiency of organic fertilizers and product quality. Reduce odor emissions and other pollutants in the production process. Help you turn into an environmentally friendly enterprise and achieve environmentally friendly production.

Although the initial investments above. In the long run, tanks for aerobic fermentation can reduce operating costs and increase the competitiveness of your fertilizers. Strengthen your position in the fertilizer market. This is your key investment choice to achieve sustainable development.

If you are interested in tanks for aerobic fermentation, Please, Contact us To obtain more information.