Uzbek company, working in the agricultural sector for many years, has won the trust of the market thanks to high-quality fertilizers. However, due to changes in market demand, Existing production equipment no longer meets the company's expansion needs. Therefore, the company decided to upgrade its production line and cooperate with us to achieve this goal.. After several rounds of technical exchange, they acquired six of our roller granulators with side discharge, forming an effective granulation group. We successfully completed the production and installation of equipment within one month, which allowed the Uzbek client to quickly put it into production. If you want produce complex fertilizers at a low price? Compound Fertilizer Extrusion Granulator Can Meet Your Needs. If you are interested, Contact us to get additional information.

What kind of productivity can these complex fertilizer extrusion granulators provide for a production line in Uzbekistan??

Each of the six side discharge roller granulators, purchased by clients from Uzbekistan, has performance 2 Tons/hour. This combination increases the overall productivity of the entire production line by up to 12 tons/time. Large volumes of high-quality complex fertilizers can be produced in a shorter time, which allows us to fully satisfy market demand. Production efficiency is significantly improved. Not only does productivity per unit of time increase, but also ensures product uniformity and quality. The high stability and low failure rate of our equipment also ensures that the entire production process runs smoothly. Downtime is reduced, thanks to which production complex fertilizers can be carried out continuously and stably.

What are the advantages of using a roller granulation plant for the production of complex fertilizers??

- High adaptability: the equipment can work with various raw materials and is suitable for production of various types of complex fertilizers. This allows Uzbek customers to flexibly adjust production volumes in accordance with changes in market demand. Supply diversified products to the market.

- Flexible production capacity adjustment: enterprises can adjust the operating mode of equipment in accordance with production needs. You can choose to run one granulator to save energy or run multiple granulators simultaneously to increase productivity. This flexibility increases the ability of businesses to adapt to market fluctuations.

- Environmental protection and energy saving: Double roll granulator uses dry granulation technology, which reduces water and energy consumption. Besides, it reduces waste emissions and meets modern environmental production standards.

What individual solutions did we offer for clients from Uzbekistan in this cooperation??

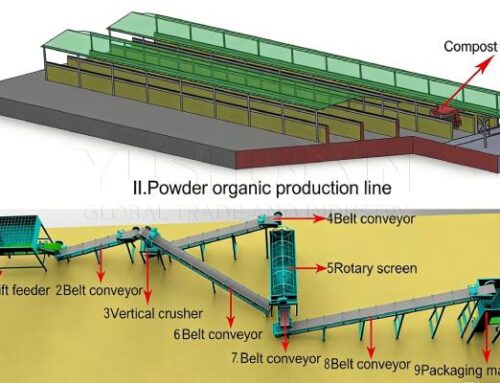

To ensure optimal equipment performance under the customer's specific operating conditions, we offer them customized design solutions. The most important, that we have custom-made large three-way distributors for customers. Taking into account the conditions of the customer’s facility, We recommend using a three-way distributor to transport powdered complex fertilizer to the roller granulator.

Three way distributor is also called disk mixer. It is usually installed above the granulator to save space. We have designed a large three-way distributor with six outlets. This design ensures uniform distribution of raw materials throughout each extrusion granulator of complex fertilizers. Optimizes the feeding process and increases production efficiency.

Are you facing similar production challenges?? Do you want to increase productivity through technological upgrades?? We invite you to contact us. We will provide you with professional advice and customized equipment solutions. Whether it is a granulator for the extrusion of combined fertilizers or granulator for the production of organic fertilizers. We will help your company achieve a competitive advantage in the market. Feel free to contact us, to find out more about our products and services.