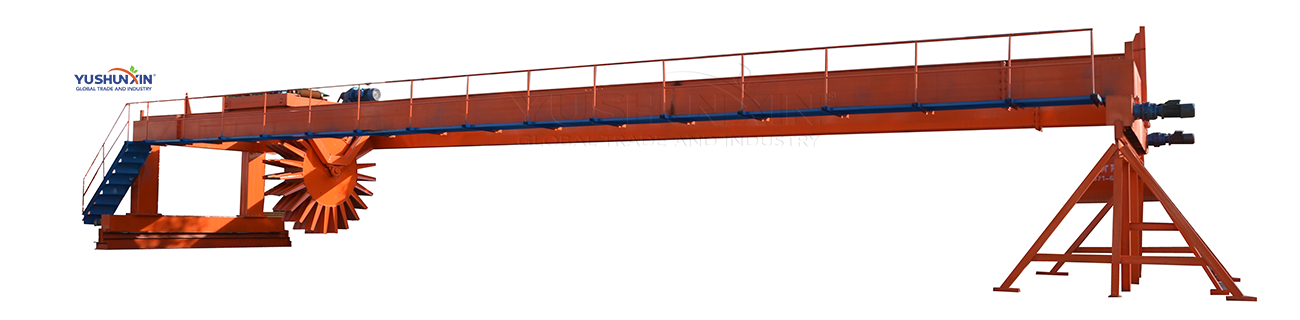

Wheel type compost turner

- Type of equipment: Equipment for fermentation

- Applicable materials: Chicken droppings, pork droppings, Korovy litter, sheep's litter and other manure of livestock

- Brand: Shunxin Machinery

- Production capacity: Tugging depth 1,5-3 meter

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from the manufacturer: Yes

Wheelchair Also called the impeller type turning machine. This is a kind automatic equipment for composting and enzymings, which is an indispensable component of the entire fertilizer production line. It is used in the process of fermentation on the line for the production of organic fertilizers. Can help you turn over and quit material, so that it is better fermented.

That the roller of the compost of the wheel -type?

A wheel current machine is suitable for fermentation and transportation of organic waste, such as the litter of livestock and poultry, sludge, straw slag and sawdust. It can be used at various workplaces, And the effect can better satisfy your needs. Besides, The roulette is turning a roulette.. It can be used in combination with solar enzymatic chambers, Enzymatic vans and machines for pumping. It can also be used in combination with the transfer machine, To implement the use of one machine with several slots, which significantly increases your production capacity.

Our wheel machine is an intensive product, which includes overturning, Staffing, Oxygenation, Crushing and mixing. It has high performance and is easy to operate, which allows you to start work in a short time. This is the best choice for your equipment for composting.

Our plant has single -disc and two -disc wheelbarrons of a wheel compost. These are two different types of rotary equipment, used to accelerate the process of composting organic waste.

What is the difference for you between these two composting devices? How do you choose?

· One -minced wheel roller roller of a wheel compost.

Single -disc roller roller of a wheel compost – This is a relatively simple mixing equipment. Usually it is equipped with one large disc with several mixing blades. When the car moves along the compost heap, The disk rotates, allowing blades to penetrate the layer of compost. Blades throw the material from the lower layer to the upper and mix it, thereby ensuring oxygen access and mixing, which contributes to the growth of microorganisms and the decomposition of organic substances. The single -disc shir of the wheel compost of a wheel character differs in a relatively simple design, low cost and ease of operation. However, due to the presence of only one disk, their mixing efficiency may be lower, than the two -disc shir -like roller.

Two -disc shir of a wheel compost.

Two -disc shir of a wheel compost. These discs are usually located in parallel and each of them is equipped with mixing blades. The principle of their work is similar. However, due to the simultaneous operation of the two discs, Two -curl roller of a wheel compost provides a large width and mixing efficiency. This type of machine is suitable for large -scale compost operations and can more effectively process large volumes of organic waste. Torpost of a wheel compost with two disks is also usually more powerful and stable, What makes them suitable for long -term work in harsh conditions.

As single -disc, So the two -currics of the wheel compost of the wheel have their own unique advantages and areas of application. The choice of a particular model will depend on your needs. You can make a decision, Based on the size of the processed volume, the size of the site, budget and the desired work efficiency.

Why do you need a rimmer of a wheel compost for a turning of your materials?

As the compost is fermented, the compost temperature will increase, but too high temperature does not contribute to survival useful microorganisms. So we do? At this moment, compost must be turned over. The compost rotor can be rotated, To turn the compost. Reduce the temperature of the compost, Putting raw materials in the air. Forming the alternating state of the average temperature-high temperature-medium temperature-high temperature, Various beneficial microorganisms can grow rapidly and multiply in a temperature range suitable for them. This can accelerate the speed of the fermentation of your compost and save time, spent on fermentation.

Besides, In the manufacture of high-quality fertilizers, it is necessary to control the carbon-aspect ratio, pH, water content and t. e. In raw materials. And this can be achieved, adding some auxiliary materials. Our layer of compost on wheels can mix raw materials and auxiliary materials well to achieve the air conditioning goal for you. You can also use our other equipment for composting, such as Caterpillar Tsarotor,Self -propelled heap.

How our roulette revolving machine works for you?

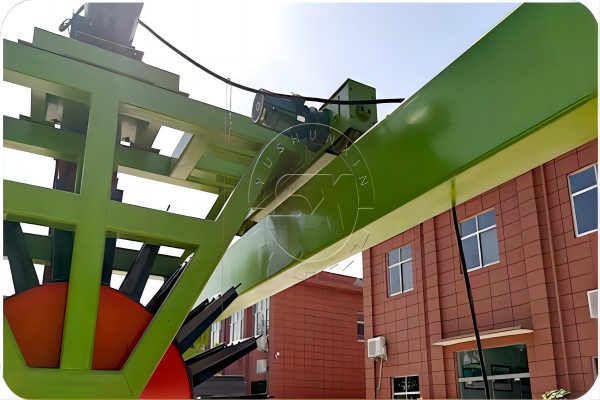

Our wheel rotating machine consists of a transmission, chassis, hydraulic lift, rotary mechanism and other main components for you. The device engine directly transfers power to the gearbox, And through the intermediate chain sets in motion two rotating disk of large diameter.

Convicted cutters on the wheel are distributed in rows and rotate at high speed for horizontal and transversal cutting operations, which can mix and mix the materials in your fermentation vat and at the same time move back. You no longer need to manually move the material back, which reduces human labor and increases the effectiveness of your work.

What are the advantages of our roller of a wheel compost, who make you buy equipment from us?

· Control of automation.

Our roller of a wheel compost of a wheel -type is centrally controlled by a control cabinet, Equipped completely Automatic electric control system, with a high degree of automation and does not require the presence of personnel during equipment operation, What reduces your labor costs.

Low energy consumption when turning.

Our roller of the wheel compost is equipped with a unique energy -saving and highly efficient gear ratio, which reduces energy consumption by 70% Compared to traditional turning equipment with the same workload, which can significantly reduce your production costs.

· No dead ends.

The canting machine of the lathe rotates symmetrically, and when a cart with a adjustable speed is displaced, it can be turned over without dead ends for you, And working ability is very strong.

How to care for a rimmer of a wheel compost, so that he serves longer?

Our machine for turning and throwing roulette will directly contact with the material during operation, and some materials are more corrosion-active. Therefore, you need to clean the mud on time in time, especially dirt on the chassis. If protective paint falls off, you need to repaint in time.

Besides, It is often necessary to check the tension of the transmission chain and adjust it in time. You can remove several links, If the chain is too free. If the rotation between the links of the chain does not work properly, You can apply the appropriate lubricant oil.

After that, how a hydraulic system will work out 200 hours, You need to clean the filter of the hydraulic system, To remove contaminants inside.

What is the price of our roller of a wheel compost for you?

The volume of production of our wheeled compost is relatively large, And the offer for customers usually makes up from 150 000 to 200 000 apiece. In accordance with the needs of different customers, the price will fluctuate, What is a normal phenomenon.

Can we satisfy the dimensional data of the roller of the compost of a wheel -type , which you want?

Certainly. The width of our roller of the wheel compost can reach 15-30 meters, The depth of rotation can reach 1,5-3 meter, and the length of the enzymatic tank should be from 50 to 200 meters, which can fully satisfy the various needs of large and small factories. For a specific equipment width, we set it up for you in accordance with your needs. The depth of turning and throwing materials, as well as the length of the container for fermentation are determined in accordance with the conditions of your plant. You can say, that the size of the entire roller of the wheel compost was developed exclusively for you.

If you want to know more about the heener compost wheeled type, You can leave us a message, And we will answer you as soon as possible during working hours.

The client's case 1 - Russian client

Russian buyers buy a double -type bore of a wheel compost for composting TBO - 16,163,888.74 rubles

FErmer in Russia opened a garbage recycling plant for organic waste processing. Contact us and hope, that we can adapt for them some equipment for composting solid household waste. Processing of organic waste fertilizer. Russian clients told us, that they built concrete containers for composting. We hope, that we can make a suitable Wheel -type compost for its normal use.

The situation at the facilities of fermentation and composting of Russian customers:

- The width of the compost concrete capacity - 10 m;

- The height of the concrete vessel (Static pile height) – 2,4 m;

- The length of the concrete capacity (The length of the car) – 110 m;

- concrete wall thickness – 0,3 m;

- raw materials - organic solid household waste.

Our compost solutions for Russian customers:

Taking into account the client’s need for large -scale composting, We recommend a double disk model – SXSLF. Composting is more effective and has great performance. Then the parameters of the dual twig a wheel compost are adjusted in accordance with the compost site of the client.

- Increase the length of the pedestrian track composter to 10 m, to adapt it to the width of the client’s site width 10 m. Make sure, that our roller of the wheel compost can smoothly move in the gutter with the width 10 meters.

- Change the size of the wheel disk to 2,4 m, to ensure compliance with the requirements of the client to the depth of composting.

- Most composter materials are made of Q235 steel. Adapt to continuous operation and problems, which can be encountered when handling solid organic household waste.

- Besides, We also equip the control cabinets of our customers with remote control handles. Convenient for customers in work.