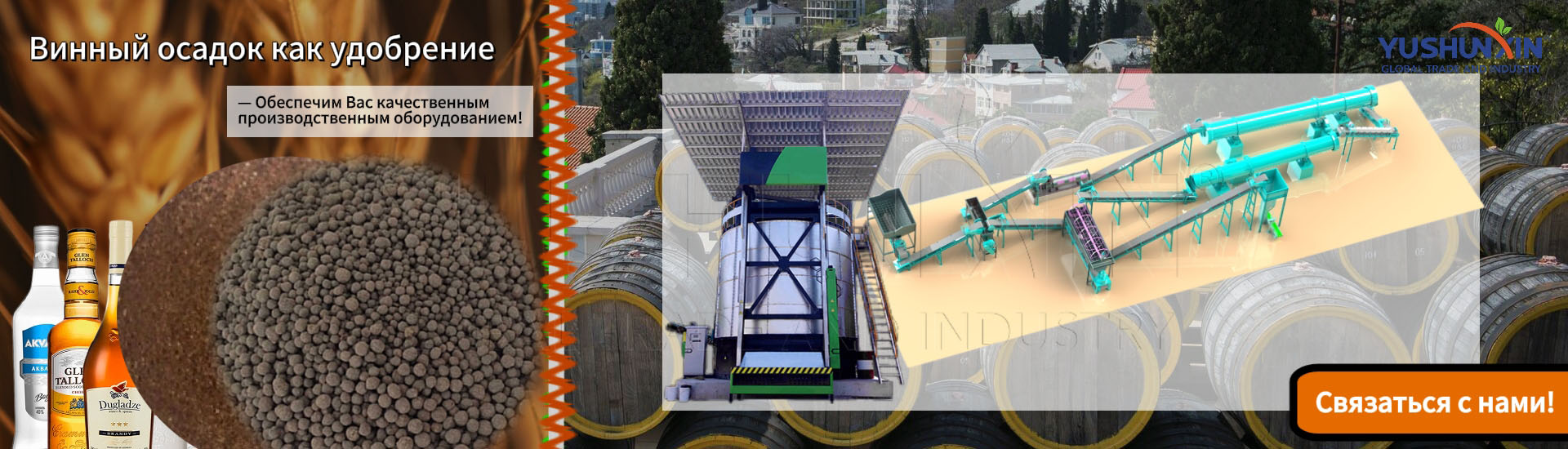

Solution: Production of organic fertilizers from wine precipitation

- Performance: 1-30 T/hour.

- Price: 390 000 rub. – 66 000 000 rub.

- Raw materials: Whenever, manure, Organic waste, nitrogen, phosphorus and potassium…

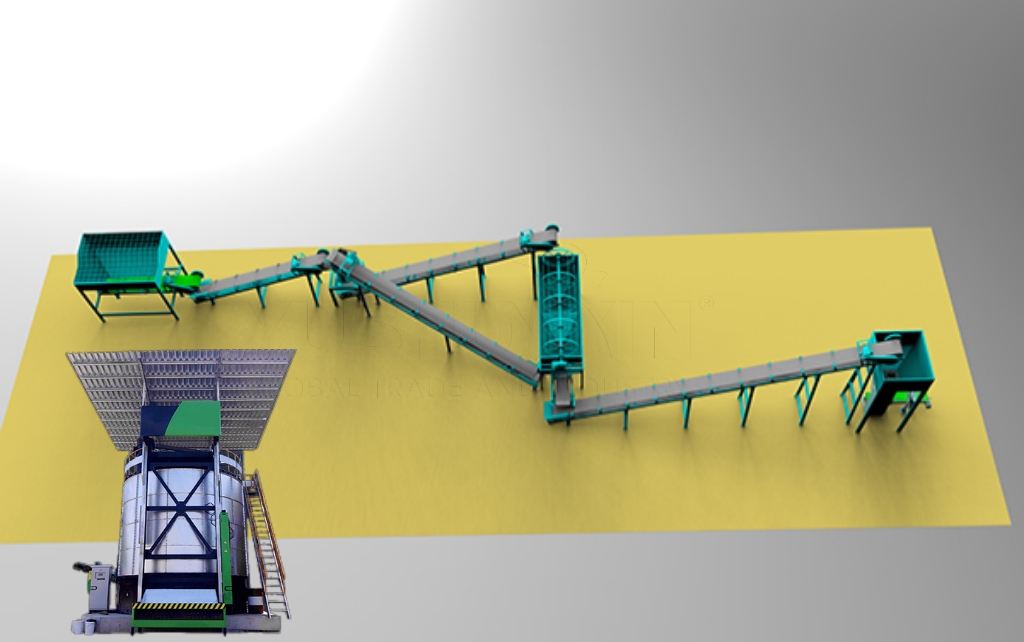

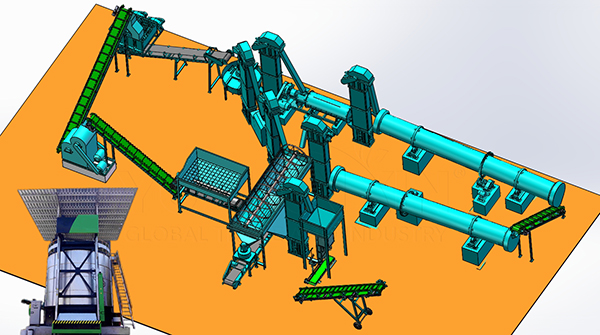

- Production line process: Crushing, fermentation, screening, Dosage, Grinding, mixing, granulation, screening, Coating, package…

In the context of sustainable agriculture, more and more attention is paid to the effective use of waste of winery enterprises. Thanks to production technology, wine precipitate of organic fertilizers can be successfully converted into organic fertilizer. Carry out the use of waste resources. As a professional manufacturer of equipment for the production of fertilizers, We provide modern equipment. Help you increase the efficiency of the processing of wine precipitate in fertilizers and help you in the production of high -quality organic fertilizers.

Using wine precipitate as fertilizer is a method, which simultaneously contributes to waste disposal and improves soil quality. Provides opportunities for the development of new products for small, medium and large wineries. We can provide you with solutions for the production line of organic wine precipitate of fertilizers, specially designed for wineries. If you are interested in obtaining more detailed information about the production line, Please, Contact us. Our professional team will provide you with comprehensive support, which will help you achieve your goals of sustainable development.

How much does it cost to invest in small -scale equipment for the production of organic fertilizers from bard? How much time will it take, To pay off?

Investing in small -scale equipment for the production of organic fertilizers from bard will cost you about 30 000 dollars. Includes equipment for processing raw materials, enzymes, Drying, crushing, begging, Packaging and transportation. How much time will it take, To recoup investments after starting the project in production? Our production line at a price has an annual production volume of about 3,000 tons. Suppose, that operating expenses, including raw materials, labor and energy, They make up approximately 10 000 US dollars.

If produced 100 tons of organic fertilizers per month and sell 150 dollars per ton, Monthly income can reach $ 15,000. Then the monthly gross profit will be $ 5,000, and annual net profit - $ 60,000. Then you can recoup investment costs for equipment in just six months.

If you are interested in this project, Contact us to develop a specific solution. Shunxin company has more than 20 years of experience in the production of equipment and customers around the world. You can contact us. We can organize detailed communication, to discuss, how to adapt a solution in accordance with market demand. And how to maximize the existing resources and technical advantages for the successful implementation of the project.

Why distillation grain can be processed into organic fertilizers?

Distillers are rich in organic substances and various nutrients, useful for plant growth, such as nitrogen, phosphorus and potassium. These elements are the key to the healthy growth of plants and help to increase the yield and quality of the crop. Besides, Organic substances in wine precipitation can improve the water -adultering capacity and breathability of the soil, and also contribute to the activity of soil microorganisms. Moreover, The sour component of wine precipitate can regulate PH of the soil and improve its structure. These characteristics make a burgundy cereal with ideal natural organic fertilizer in agricultural production. This not only reduces waste emissions and environmental pollution, but also supports the development of the closed cycle economy.

Production process wine precipitate as fertilizer.

- Collect wine precipitate as the main raw material. In this case, as necessary, you can add auxiliary materials. Such as droplings and birds, straw, sawdust, etc.. e. To adjust the ratio of carbon and nitrogen.

- Grind or pre -process raw materials to increase the efficiency of enzyme.

- Mix the sediment with other auxiliary materials according to the fermentation recipe. And adjust the appropriate moisture content (Usually 50-60%) and the ratio of carbon and nitrogen (Usually from 25:1 to 30:1).

- You can add biological monoculants, To speed up the fermentation process.

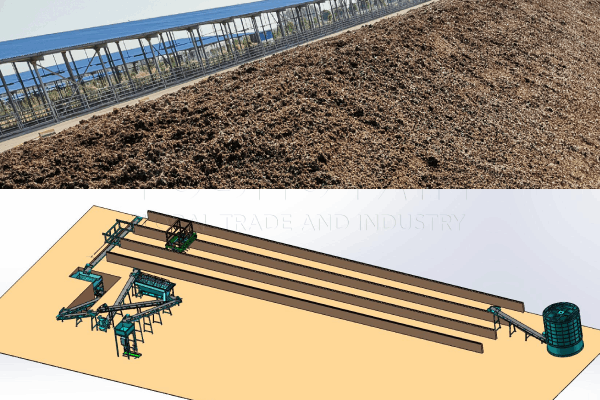

- Place a bunch of a mixture in Featman and regularly turn it over. Maintain good ventilation and uniform temperature distribution.

- During fermentation, you should always monitor such parameters, Like the temperature of the stack, humidity, value pH and t. e. Typically, the fermentation temperature should be maintained at 50–70 ℃.

- Fermentation time is usually 10-15 days. Signs of maturity are then, that the color of the material becomes darker, raw fiber decomposes and there is no specific smell.

- After the completion of fermentation, further drying is carried out, To reduce moisture content to a safe storage level (Usually less 20%).

- Fermented organic fertilizer wine precipitate is additionally crushed, To facilitate the receipt of granules.

- Use special equipment for pressing the dried material in a granular form. Our Granulator of organic fertilizers Ideal for granulum wine precipitate.

- Drying reduces the humidity of the material to improve stability in the storage and fluidity of granular fertilizers. Prevent the appearance of mold or tracking due to excessive humidity during storage.

- Cooling reduces the temperature of the pellet and adapts them to the conditions of packaging and storage. And improve the hardness of the particles and reduce the speed of the breakdown.

- When sifting, large pieces of material are removed, which are not completely split, which allows you to improve the quality of fertilizers.

- Pack, Store or sell ready -made organic fertilizers.

What wine precipitate can be used to produce organic fertilizers?

Not all types of burglar waste are suitable for use in the production of organic fertilizers. Generally speaking, Waste of natural fermentation processes, Such as wine, beer, rice wine and alcohol, most suitable for fertilizer production. Because these precipitation contain less chemical residues and have a more balanced composition. These wine precipitate as fertilizer, You can better turn organic fertilizers into nutrients rich in nutrients. Generally, The use of sediment from the production of organic wine provides organic certification of your final fertilizer product.

What is the most important stage in the production of wine precipitate as fertilizer?

The key stage in the use of bards as a fertilizer: Fermented compost..

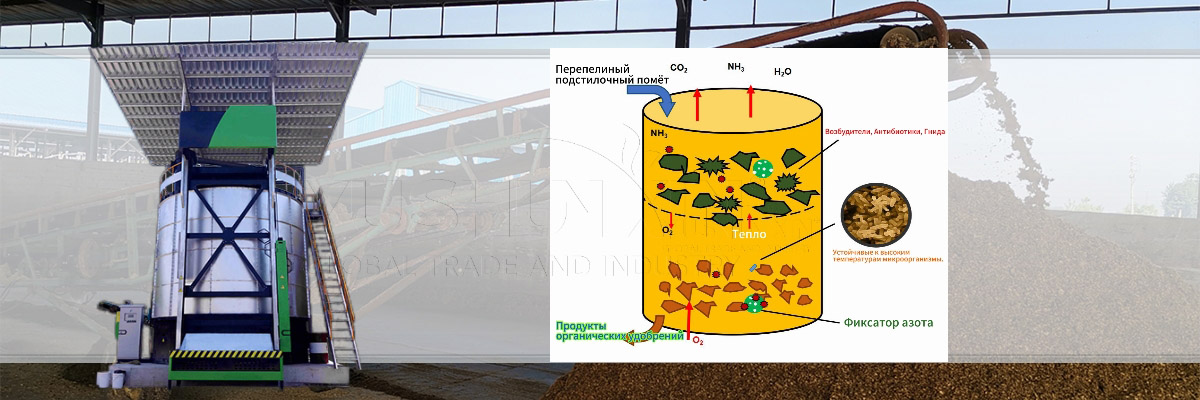

The process of fermentation effectively reduces the acidity and content of alcohol in wine precipitation. In this case, organic substances are decomposed by the activity of microorganisms and nutrients are released. Plants are easier to absorb. Proper fermentation can also reduce the amount of harmful substances and prevent the appearance of pests and diseases. Improve the overall quality of the finished fertilizer. To ensure effective fermentation, You need to control the corresponding temperature, Humidity and ventilation conditions. It is also necessary to add the corresponding number of auxiliary materials, such as straw or droppings and birds. To adjust the ratio of carbon and nitrogen and accelerate the process of fermentation.

What fermentation equipment can we provide you for the production of organic fertilizers from distillates grain?

We have a lot Turning cars, such as Wheel -type compost, Milot -shaped stumber of compost, self -propelled composter etc.. But what is more suitable for you wine sediment as fertilizer, So this is production fermentation containers for organic fertilizers.

A container for fermentation of organic fertilizers is modern and effective equipment for fermentation. Ideal for the disposal of organic waste, such as wine precipitate. The enzymatic reservoir occupies a small area and is suitable for such situations, Like winery, where the production space is limited. Accurately controlling the conditions of enzyme, You can produce organic fertilizers of more uniform and stable quality. Our tanks for the fermentation of organic fertilizers are highly automated, they are easy to control and manage. Will help you reduce the complexity and complexity of manual operations.

What questions should you pay attention to during the fermentation and composting of wine sediment?

During the process of composting wine sediment, it is necessary to pay close attention to several key factors. To guarantee, that the process of composting wine sediment proceeds smoothly and reaches the perfect fertilizer effect. How to effectively manage and regulate these factors? We offer you several methods. They can help you ensure the effective course of the process of composting wine sediment and ultimately get high -quality organic fertilizer.

- Importance: The ratio of carbon and nitrogen refers to the ratio of carbon and nitrogen in the composted material. The corresponding ratio of carbon and nitrogen is the basis for ensuring the normal activity of microorganisms.

- Correction method: Wine precipitate is usually rich in nitrogen. Therefore, you need to add some materials with a high carbon content (For example, straw, sawdust), to achieve the ideal ratio C:N. Excessive nitrogen content will lead to the release of ammonia and the appearance of the smell. Too high carbon content will slow down the decomposition process.

- Importance: Moisture is a prerequisite for microbial activity. Corresponding humidity contributes to the growth and reproduction of microorganisms.

- Correction method: The wine residue itself has a high water content, and dry materials must be added in the corresponding quantities depending on the situation. If the compost material is too dry, You can spray water to increase humidity. If it is too wet, You need to increase the frequency of use of the layer of compost or add moisture -absorbing materials.

- Importance: The composting process is a biochemical reaction, in which aerobic microorganisms dominate. Therefore, a sufficient amount of oxygen is the key to maintaining its activity.

- Operation method: Regular use of composters for turning a heap can increase air circulation. Prevents the formation of anaerobic conditions. Thereby reducing the formation of smells and greenhouse gases, such as methane.

- Importance: Increasing temperature during composting is the result of microbial activity. The corresponding temperature range can accelerate the decomposition of organic matter and the destruction of pathogens.

- Management method: At the early stage of composting, the temperature will grow rapidly and can be maintained from 45 ℃ to 65 ℃. Higher temperatures can kill beneficial microorganisms, while too low temperature means slow decomposition rate. The temperature can be controlled, regularly turning the composter and regulating the proportion of compost materials.

What are the characteristics of the line for the production of powdered wine precipitation of organic fertilizers, which we have developed for small winery enterprises?

For small winery enterprises, we have developed a compact line for the production of powdered organic fertilizers. Investment costs are small and make up about 30 000–50 000 US dollars. But all the necessary stages of processing are covered for you. This production line includes equipment for preliminary processing, Fermentation system, Drying equipment, crusher, sifting a car, packaging machine and t. e. It is characterized by ease of operation and low maintenance costs. Our solutions can be adapted to wine conditions. Help small wineries effectively use the resources of grain waste of distillery plants.

Why are large brewery more suitable for the production of granular organic fertilizers from wine precipitate?

Large breweries daily produce a large amount of waste wine precipitate. Raw materials for production are enough. And large breweries can afford to invest in an effective, Automated production equipment. It can better process distillate grain and produce organic fertilizers. Large breweries can reduce production costs due to mass production of granular organic fertilizers made of distillated grain. At the same time, they can take advantage of the scale effect to increase profit. When selling these organic fertilizers, since the brewery has a strong influence of the brand and market channels, He can more effectively promote his granular products of organic fertilizers.

In addition to wine precipitate as fertilizer, We also have Organic fertilizers from chicken manure, Organic fertilizers from cow manure, organic fertilizers made of brown coal and other production solutions. If you are interested, Please, Contact us! Welcome to visit our factory and company. Let's meet face to face, To discuss a fertilizer production decision, which is suitable for you.