In recent years, more and more Ukrainian enterprises, engaged in the production of organic fertilizers, strive to improve the efficiency of manure composting. One of these clients is a large organic fertilizer plant.. His main request was the need to purchase composting equipment with high productivity and process automation. After a thorough analysis of production tasks and studying the recommendations of partners, the company decided to purchase several fermentation tanks and two tracked composting machines. This choice allowed us to increase the volume of manure processing, minimize labor costs and improve the quality of the final product. If your company has similar tasks, we are ready to offer you the optimal comprehensive solution.

Why should enterprises buy composting equipment for intensive manure processing??

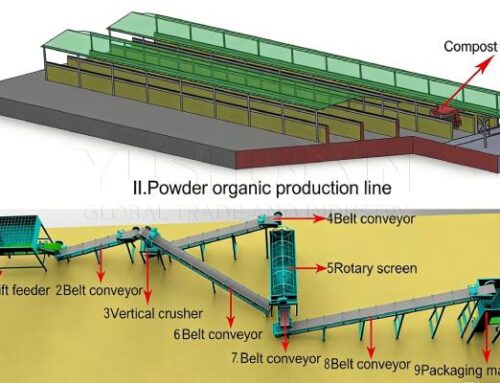

Composting organic waste requires a professional approach, especially when it comes to large volumes. Many businesses are faced with the need to purchase composting equipment., to cope with daily production pressures. The use of modern fermentation tanks significantly speeds up the process of manure decomposition, and the tracked composting machine ensures regular mixing and saturation of the mass with oxygen. This solution allows you to increase the efficiency of fertilizer production, reduce processing time and reduce raw material storage costs. Besides, automation promotes compliance with sanitary requirements and guarantees consistent quality of the final product. Ukrainian enterprises regularly note the advantages of a systematic approach, investing in industrial grade composting equipment.

What benefits does process automation bring when choosing equipment for manure composting??

In modern conditions, automation is becoming a key factor in the successful operation of enterprises., employed in the production of fertilizers. Implementation of modern solutions, such as composting equipment, gives opportunity control temperature parameters, humidity and mixing with virtually no human intervention. This, In turn, reduces personnel costs and reduces the risk of errors. Tracked composting machine ensures even processing of compost, which has a positive effect on the physical and chemical properties of the finished fertilizer. Modern control systems can be easily integrated into existing production lines, ensuring smooth operation of the enterprise. Our clients confirm, that process automation using composting technology increases productivity and saves resources.

How equipment supplier experience affects the stability of fertilizer production?

Choosing a reliable partner is an important step for any large enterprise. Our Ukrainian customer contacted us on the recommendation of a partner, which immediately allowed us to establish trusting relationships. We offered him a customized solution - the supply of several fermentation tanks and two tracked composting machines, fully meeting the requirements of the enterprise. Our team provided support at every stage: from equipment selection to implementation and personnel training. This approach helps the customer quickly integrate purchased equipment into the production process and minimize downtime. Many years of experience, A wide range of composting equipment and ongoing technical support help reduce risks and achieve sustainable operation throughout the entire service life. Partners value not only the quality of equipment, but also a high level of service.

Tracked composting machine in operation

In conclusion, it is worth noting, that a systematic approach to the selection of composting equipment ensures stable processing of manure and high quality of the final product. Our solutions help enterprises automate and optimize production. We are ready to offer a wide range fertilizer production equipment and guarantee professional support at all stages of cooperation. If you have questions or are planning to purchase composting equipment, we are always in touch.