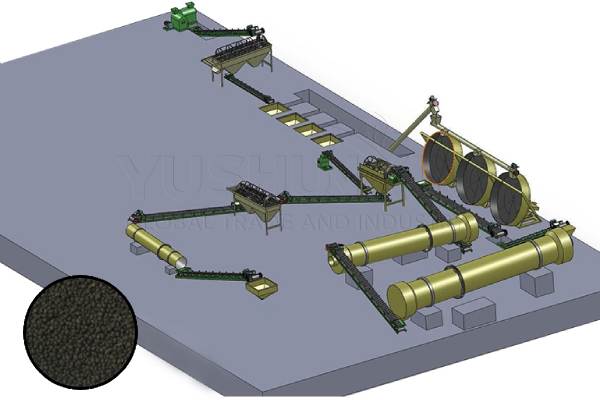

Ukrainian client supports call for green development of local agriculture. The client plans to build an organic fertilizer production plant with the capacity 100 000 tons per year. After repeated market research and comparisons, the client ultimately concluded a contract with us to purchase the equipment. The parties jointly promote the launch of an organic fertilizer production plant. If you have similar needs in construction of a plant or purchase of equipment, Please, Contact us for consultation.

How to accurately select equipment for an organic fertilizer production plant with productivity 100 000 tons per year?

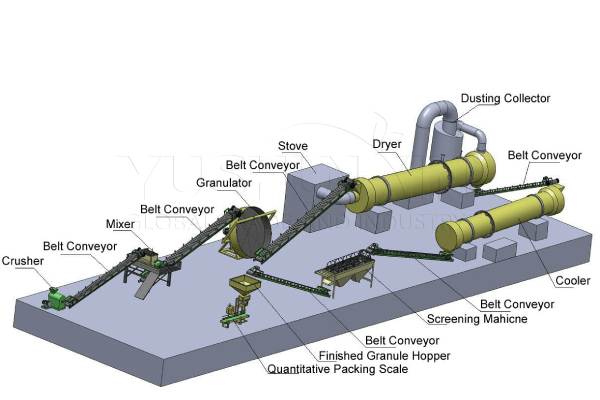

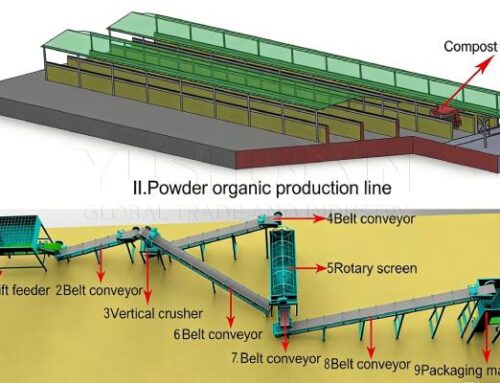

The client clearly stated the main purpose when requesting. His goal is to achieve productivity 100 000 tons of organic fertilizers per year. At the same time, the equipment must meet the characteristics of local raw materials in Ukraine. The equipment must also comply with Ukrainian environmental standards. Our business team, based on performance requirements, accurately calculated key equipment parameters. Options include model, power, performance and others. Given strict local environmental regulations, we included environmental modules in the equipment package. Modules cover exhaust gas treatment, recycling Dust and others. This ensures that the equipment operates in accordance with local environmental requirements.. If you have questions about selecting performance or choosing equipment, you can contact us at any time to receive professional advice.

How to ensure efficient delivery and installation of equipment for an organic fertilizer production plant?

How to build an after-sales service system for organic fertilizer plant equipment with productivity 100 000 tons per year?

If you have plans to build a plant for the production of organic fertilizers or need to purchase and customize equipment, Please, contact us for consultation and purchase. No matter, Do you have any questions about performance selection?, or doubts about the choice of equipment. No matter, would you like to learn about the process of cross-border cooperation, our professional team will provide detailed answers. We will provide comprehensive support and work with you to create a new future for green agricultural development.