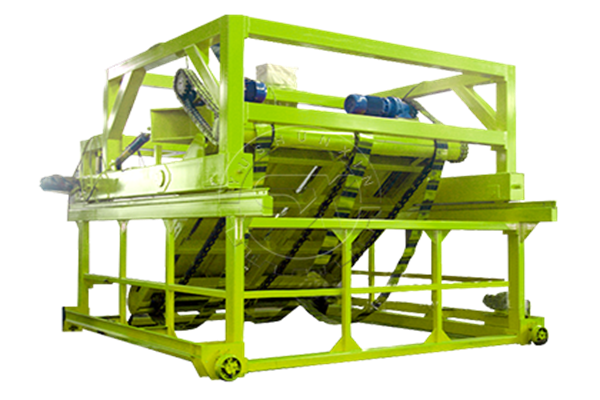

Chain plate type compost turner

- Type of equipment: Equipment for fermentation

- Applicable materials: Chicken droppings, pork droppings, Korovy litter, sheep's litter and other manure of livestock

- Brand: Shunxin Machinery

- Production capacity: Custom

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from the manufacturer: Yes

Chain plate type compost turner It is effective equipment for the production of organic fertilizers. Its demand in the market is growing every day. It not only turns agricultural and organic waste into fertilizers, useful for the soil. It also has such advantages, as a simplicity of operation, low environmental impact and high economic benefit. We strive to provide you with high -quality products and services for composters with chain plates. For you to achieve optimal performance and return on investment.

What are the components of the plate-chain composter?

- 1

Chain conveyor system: This is the main component of the chain composter. Including the chain plate, drive shaft, Asterisk, Supported shaft and other connecting parts. The chain plate consists of several plates, connected by chains, forming a continuous conveyor tape. Used to move and turning materials.

- 2

Frame design: Provides stable support, guaranteeing the stability and durability of the machine during operation. The frame is usually made of high -strength steel. Maintain pressure and load, arising in the process of composting.

- 3

Drive device: Including the engine, gearbox, Asterisk and other components. Used to actle the chain plate conveyor system. This moves the material forward and turns.

- 4

Turning mechanism: Turning device, installed on the system of transportation of chain plates. For example, turning blades or teeth of rake, materials used to rotate. Increase the contact between materials and air, and also increase the rate of oxidation and fermentation of compost.

- 5

Management system: It can be a simple manual control device or a more complex automatic or semi -automatic control system. The control system is used to adjust the operating speed of the machine, rotation frequencies and other parameters. Achieve optimal composting results.

- 6

Moving trolley: The chain plate storage of compost is usually equipped with a displacing cart (used in the method of composting with a trough). This allows the machine to move forward and back along the layout. It is convenient for you to manage composting operations.

- 7

Protective devices: For example, Protective covers or protective nets. It is used to ensure the safety of operators and prevent random injuries during operation.

- 8

Power supply system: provides a composter with the necessary power. Cable drums may include this, Distribution boxes and t. e.

- 9

Auxiliary system: can turn on the lubricant system, cooling system or dust collecting system and t. e. Ensure stable work of the composter with a chain plate for a long time.

As a chain plate storage of compost processes materials and produces high -quality organic fertilizers for you?

The composter with chain plates automatically transport and process organic waste using the built -in transportation system with chain plates. During operation, the machine loads raw materials to the strip conveyor, such as maneuvering animal and plant origin, agricultural waste and t. e. Then the material is transported along the ways of equipment using a chain plate with a drive from the engine.

In the process of transportation, materials are continuously turned over and mixed with a swing-method, installed on the chain plate. This action increases the contact of the material with the air and promotes decomposing activity Microorganisms. Accelerates the process of composting organic substances. The operator can adjust the operating parameters of the machine through the control system. Real time monitoring and automatic adjustment of temperature and humidity of the compost medium. Thereby optimizing the process of composting.

After a series of transportation, Turning and mixing materials complete the process of composting. Finally, It is unloaded from the machine for further processing or direct use. The design of the composter with chain plates makes the process of composting continuous and automated. This significantly increases the efficiency and quality of composting, simultaneously reducing the load on manual labor.

What is the current price of a plate-chain composter at our factory?

The market price of a plate-custom composter depends on many factors. Since we are a source of direct sales from the factory, price, which we give you, much more profitable, than other merchants. The smallest or simple plate-braid composters at our enterprise, probably, will be cheaper: from several thousand to tens of thousands of dollars. Medium -sized machines, suitable for medium -sized manufacturing enterprises, can cost from tens to hundreds of thousands of dollars. Large, Highly automated and individual composters with plate chains may require higher investments. The price can be calculated hundreds of thousands of dollars.

If you want to get accurate price information, It is best to contact us directly. Get detailed information about prices and possible discounts and promotions. Besides, You will need to take into account possible delivery costs, installation, as well as any necessary costs for maintenance and operation training. These are additional costs, which you should take into account when buying a chain plate bore of the compost.

How long will our composter with chain plates last you?

Under ideal conditions of maintenance and operation, a high -quality chain plate bore of the compost can last more 10 years. However, in real conditions, its service life may be reduced due to improper operation, insufficient maintenance or harsh environmental conditions.

Generally speaking, subject to normal use and proper service, the service life of our plate composter is usually about 10 years. For equipment, which is often used, poorly served or works in extreme conditions. The service life may be from 5 to 8 years. Against, If the machine is very well served and used carefully, The service life may exceed 15 years.

What can you do, to extend the service life of your chain composter?

- Strictly follow the instructions of the manufacturer for operation and maintenance.

- Use recommended accessories and consumables.

- Carry out regular preventive examinations.

- Proper training of operating staff.

- Avoid overload and abuse of equipment.

- Replace worn parts in a timely manner.

What can we offer you, as a manufacturer of plate-chain composters?

Depending on your specific needs, we can provide services for individual design and production of composters with chain plates. Whether it is computing power, car size or functions. We can guarantee, that the product perfectly complies with your workplace and production requirements.

Our professional team will provide you with comprehensive installation and commissioning services. Make sure, that the composter with chain plates can be immediately put into production and works uninterruptedly after delivery.

We provide comprehensive after -sales maintenance and technical support. Includes, Among other things, Operational training, maintenance manual, supply of spare parts and elimination of malfunctions. We strive to provide you with the most efficient use of our equipment and the achievement of long -term and efficient production.

In addition to a chain plate storage of compost, We also produce other types of equipment for composting. For example, Armor reservoirs, Caterpillar composters and t. e. Full solution for composting, specially designed for you. Besides, We also provide a full set of equipment for the production line. Ensure the uninterrupted and effectiveness of the entire process of production of organic fertilizers. From pre -processing equipment, such as crushers And the mixers, to equipment for subsequent processing, such as sifting and packaging machines. As well as auxiliary transport systems and automated control systems. We hope for cooperation with you to promote the future of sustainable agriculture.