Disc mixer

- Performance: 2-12 (subject)

- Type of equipment: Mixing equipment

- The materials used:

- Applicable materials:Organic fertilizers, Complex fertilizers, NPK fertilizers, Complex fertilizer

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from the manufacturer: Yes

Vertical mixer, also known as a disk mixer, disk mixer, is one of the special mixers in the fertilizer industry. In the fertilizer industry, many customers use it to produce a mixture of organic fertilizers, complex fertilizers and so on. Of course, It can be used in other sectors. Our company Shunsin is a professional manufacturer of fertilizer equipment. We can provide you with high -quality disk mixers. You can choose in accordance with your various production needs.

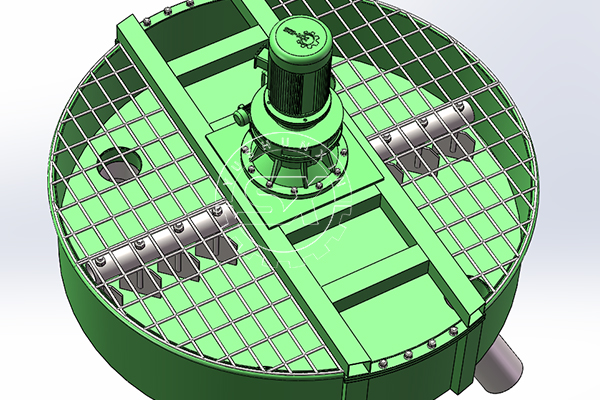

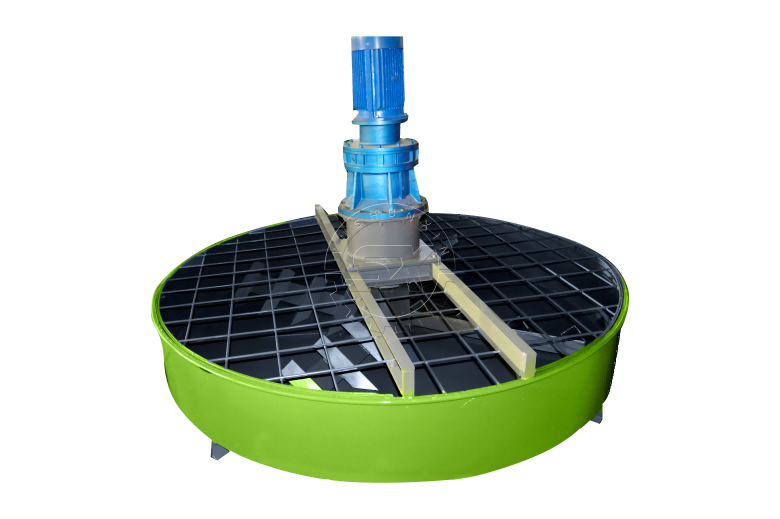

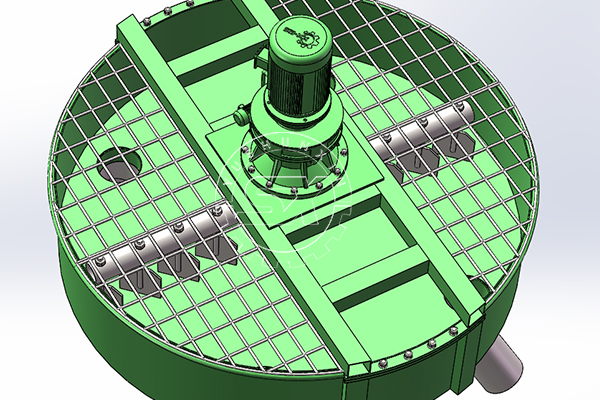

The structure of our mixer.

To give you the best idea of this equipment, We divided the desktop mixer into three parts. This is part of the frame, Part of the transmission connection and part of the mixing.

- The frame part is designed to install all the working bodies of the disk mixer, made from high -quality carbon sheets Stali and Schwellera cooked, For her bearing capacity, you can not worry at all.

- For the link of the transmission of the disk mixer, we have chosen for you Cycloidal gearbox, so that the equipment can work uninterruptedly. And this is a low noise level, which to a greater extent meets the requirements of environmental protection in the current era.

- The mixing part of the vertical mixer is designed for uniform mixing of materials in the mixing chamber, so that your subsequent work on Tarelly granulator Could be done better.

How our disc mixer does the work on mixing for you?

After that, How the machine is turned on, You need to send the material to the loading port of the vertical mixer through The strip conveyor. The engine of the mixer drives the gearbox, And the work of the gearbox sets the main shaft in motion. We welded a lot of mixing blades to the main shaft, and mixing blades will completely mix your materials, and then unload them through the outlet.

Why can our disk mixer be your choice for mixing different ingredients?

- For organic fertilizers, After mixing organic fertilizer and straw powder through a vertical mixer, The contact area between them can be increased, So Aerobic fermentation organic fertilizer can be performed better, and the composting process can be accelerated.

- For complex fertilizers, our disk mixer can completely and evenly mix various chemical raw materials, To help you make higher quality fertilizers.

What stationary mixers, in demand, We offer you to choose from?

I currently have no five types of disk mixers, performance 2-12 subject, And they are all very popular among customers. You can choose a disk mixer, which is suitable for you in accordance with your production needs.

The SXPJ-1600 disk mixer has a productivity of 2-4t/h, And for you a gearbox BLD15-87 is used, At a speed of 16r/min. Suitable for your small production. If you need to produce 3-5 T of fertilizers per hour, You can choose a vertical mixer SXPJ-1800. If you are an enterprise of medium size, You can choose the SXPJ-2000 disk mixer, whose performance is 4-6 subject. SXPJ-2200 performance is about 6-8 subject. All four of the above mixers use the BLD15-87 gearbox with speed 16 rpm, which provides uninterrupted work.

The last disk mixer SXPJ-3000 is more suitable for large factories, And its performance can reach order 8-12 T per hour. And gearbox, which we use for you, – XLD9-87, And the speed is the same, Like other types of mixers, 16 rpm.

If you do not know, How to choose, You can tell us about your situation, And we will make several professional offers for you.

Why do many customers choose our disk mixer?

Call the number below, to contact us, or leave your contact details and wait, While we contact you.