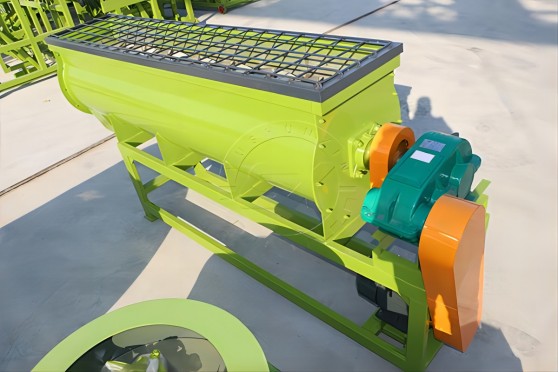

Single shafts mixer

- Performance: 2-5 (subject)

- Type of equipment: Mixing equipment

- The materials used: Organic fertilizers, Complex fertilizers, NPK fertilizers, Complex fertilizer

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from the manufacturer: Yes

Continuous, also known as one mixer, is a type of horizontal mixer. Cause, by which it is called single, lies in that, that he has only one stirring rotor. This is an indispensable auxiliary equipment in the production of fertilizers, And most people use it to mix organic fertilizers and complex fertilizers. Certainly, It can also be used in the chemical industry, building materials and other industries.

The performance of our one mixer is 2-5 subject, And the mixing time is about 3-5 minutes. Usually, We place it after a metering machine for uniform mixing of powder materials. It is also convenient to use the subsequent Tarelly granulator or Two -wool granulator, such as roller granulator, For granulation.

Our single shaft mixer consists of mixing shaft, mixing blades, mixing chambers, engine, gearbox, etc.. As he also performs a work on mixing for you? The mixing blade of a one mixer rotates, Raising the material to a certain height. Then let him fall freely, to complete the mixing process. The material is continuously and continuously circulated in all directions in the tank of the machine. Achieve fast and even mixing effect, so you can get the perfect state of material.

Our one -time mixers can provide continuous production and are the best choice for your work to mix raw materials.

To reduce equipment wear, What materials did we use to make a suitable one of a continuous mixer for you?

To seal the shaft of the single shaft mixer, we use multi-groove labyrinth and stuffing box combination seal for you, which is very reliable and has less shaft wear.

The lining of the mixer body is made for you from wear -resistant alloy. Such material can extend the service life of the equipment and avoid the self -consumption of materials, caused by an excessive clearance after wear, which leads to large losses of your materials.

How do we solve the problem of sticking the material for you on the wall of the barrel of a single mixer?

For you we added Vibration system To your one mixer. This can help you solve the problem, consisting in that, that sticky dust easily sticks to the cylinder wall. The connection between the mixer body and the base is an elastic connection. So you don't need to worry about that, that the vibration system will seriously affect the equipment.

How our one mixer can reduce unloading time for you?

The unloading door of our one mixer opens and closes around the door shaft, set in motion by the power mechanism, and it does not need to be opened and closed manually. Reduce the load on the operators and reduce your labor costs. He is installed at the bottom of the bowl of a one continuous blender and intersects along the entire length of the bottom. When the fasting door opens, All materials can be unloaded. It not only takes a short time, but there is no material left in the mixer, which effectively reduces your production costs.

Can you choose a stirring device of a single -action mixer?

Certainly. There are many types of our none of the mixing devices, You can choose a pear -shaped knife, Ribbon, lobed, And we can also add a flying knife for special materials. Different mixing devices are used for different materials. If you do not know, How to choose, You can tell us your raw materials, And we can provide you some links.

Which of our wealthy mixers are popular with customers?

We currently have two single shaft continuous mixers, and they are very popular among customers. You can choose according to your production requirements.

The productivity of the single-shaft mixer SXWJ-70 is 2-3 subject, and you use a ZQ350-23.34 gearbox, which can reach 46 rpm, what is suitable for some small factories. If your scale is not very large, You can choose this.

If you have an idea to purchase a single shaft continuous mixer, Please, contact us constantly. Or leave your contact details, we will contact you within 24 hours.