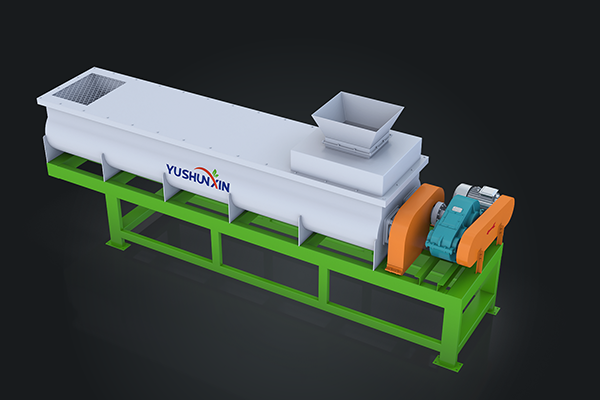

Double shafts horizontal mixer

- Production capacity: Mixing speed 35 (rpm)

- Type of equipment: Mixing equipment

- The materials used: Organic fertilizers, Complex fertilizers, NPK fertilizers, Complex fertilizer

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from the manufacturer: Yes

A double -sized lobed mixer, Also known as a double -sized mixer, Twarge horizontal mixer, suitable for many industries and is indispensable in the production of fertilizers.

A double -gling horizontal mixer mainly consists of a case, node of the screw shaft, drive device, pipeline, covers, chain covers and other components. It is used to mix proportional materials and preliminary preparation for the granulation process. A double -shit mixer can evenly mix the materials, which you mixed, and at the same time compact materials, which is convenient to use Tarelly granulator and other granulation equipment for subsequent granulation.

Uniform spraying of water into the mixture in a double mixing tank and mixing the mixing blade. Forms for you fluffy cores of various sizes. This saves a certain amount of time for the granulator. The entire mixing process is divided into three zones: The spray zone, mixing zone and unloading area. Twarge horizontal mixer has triple moisturizing functions, mixing and feeding. He can not only evenly mix the materials, but also effectively improve their characteristics..

In our horizontal mixer, the input opening for feed is located at the top, and the exhaust hole below. 2-5 minutes, which can provide continuous mass production for you. He also adds to you a flexible and reliable electrical control system. Let you manage a double -grinding horizontal mixer is safer and comfortable.

What materials did we use for you during the manufacture of a double -sized horizontal mixer?

For the frame of the double -grinding mixer, we use a thickened groove slab, which is made by welding. Make sure, that you have good and stable performance during use.

The body of the double -grinding mixer is made of sheet and steel. We weld him, To give him a form, and collect it with other components before sending you.

For the nozzle of the pipeline of a biaspit horizontal mixer, we use for you a physico-chemical conical spraying group made of stainless steel, which has a simple design and is easily replaced. Besides, stainless steel material is more resistant to corrosion and durable, which can effectively reduce your costs in the process of fertilizer production.

Why install a protective screen on the upper part of the double -shit mixer you bought?

On top of a double -grinding mixer we install a protective screen for two targets.

Protective screen can crush some larger materials, Reduce resistance, which is faced with a horizontal mixer during operation, and increase the efficiency of your production. This is one of the reasons.

On the other side, The protective screen can prevent a random drop in the workers in a bicshoid horizontal mixer. Protective screen, installed on our double -shit mixer, made from sono recovery, who have a strong supporting support and do not break, Therefore, the safety of your staff can be guaranteed.

How our two -sneaker horizontal mixer regulates the moisture content of your material?

We installed for you inside a double -suscoming mixer a watering and moisture -regulating pipes, which are axial along the direction of the screw, so that you can form a water curtain and evenly spray it to the material. You can adjust the moisture content of the material in the mixer, manipulating a manual control valve on a water supply pipe. We suggest you adjust the moisture content of the material in a double -grinding mixer to 25%-30%, which is convenient for the granulator to perform the granulation process.

What can you do, to change the performance of your horizontal lobed mixer?

You should know, that different users present different requirements for the uniformity of mixing and the time of transportation of their materials. For this reason, we specifically designed the blades of the double -grinding mixer in this way, so that their angle can be adjusted. You can change the performance of the mixer, adjusting the angle of tilt. The method of attaching the blade of a double -grinding mixer can also be selected in accordance with your needs: We have a type of welding and floating type. Besides, We have developed for you a mobile door of a double -shit mixer, so that you can conveniently clean the materials in the car.

Is it possible to adjust the defense of a two -sopter mixer?

Certainly. Currently, we have two two -sized horizontal mixers, Namely, the SXSJ-8030 double-gripping mixer and the SXSJ-1050 double-shine mixer. Both blends received enthusiastic customer reviews. The SXSJ-8030 double-shit mixer is equipped with a ZQ350-31.5 gearbox, And the SXSJ-1050 is equipped with a ZQ500-31.5 gearbox. The turnover of the rotation of these two two -sled mixers is 35 rpm. You can regulate the turnover of the rotation of a bicentric lobed mixer using a computer in accordance with the needs of various mixing volumes, since the control of the rotation of the rotation can control the size of the flow.

What do you need to do, to save a lobed granulator with two ramparts, so that he serves longer?

After starting, you must pay attention to, Are various parts of a two -wry mixer work normally. When the machine temporarily stops working, You need to check, Whether the mixer's blades are bent, Whether the screws weakened or did not drop. Every time, when the machine is not used, you must pull the switch down in time, to ensure security. If you do not use a two -wry mixer for a long time, You must monitor that, so that the mixer is clean inside.

Besides, You also need to check regularly, Are there any damage to various components. And every time you turn on you need Lubricate the gears Twarrof mixer. Every two months you need to change oil in the gearbox. Every six months you need to change the oil in the gearbox to a new.

If you want to know the price of a double -sized lobe mixer and set other types of mixers for example disk mixer questions, You can contact our customer service personnel. Or you can leave your contact information, And our customer work experts will contact you.

Frequently asked questions about the mixers of the doubles.

Twarge mixer – This is a mixing device, having two stirnels. Each axis has a blades or other types of mixing elements. This design allows you to effectively increase the efficiency and uniformity of mixing, especially suitable for processing materials with high viscosity, a significant difference in density or containing large solid particles. The use of a double -sized mixer is the following:

Building materials: In the manufacture of dry building mixtures, cement mixtures, thermal insulation solution, waterproof materials and other products, A double -shit mixer with blade screws provides quick and uniform mixing.

Chemical industry: Used to mix various chemical raw materials, suspensions and homogenization. For example, Plastic granules, Fertilizers, pigments, adhesives, etc..

Food industry: A double -sized mixer can process such foods, Like dough, minced meat, syrups, etc., Providing the uniformity of the texture of the mixture.

Pharmaceutical industry: It is used to mix various powders and viscous materials in the production process of drugs, guaranteeing the uniform distribution of components.

Ecological industry: Mixing and stabilization of chemicals in environmental projects, such as sedimentation processing and hard waste processing. And cleaning suspended substances in wastewater.

Feed production: Mixing various feed components, Such as grain, additives, nutrients etc., for the production of homogeneous animal feed.

Powder industry: Used to mix various powders and particles, such as dry colors, Metal powders, etc..

Energy industry: In the production of biomass energy, it is used to mix the source materials, such as wood chips, straw, etc., In order to improve the quality of biofuel.

A double -sized mixer is usually developed taking into account high shift loads and complex mixing tasks. It effectively processes materials with high viscosity, lumps prone to the formation of lumps or requiring quick mixing. Various designs of double -shaft mixers (Types of blades, way of their placement, rotation speed, etc.) can be adapted to specific Characteristics of materials and applications requirements.