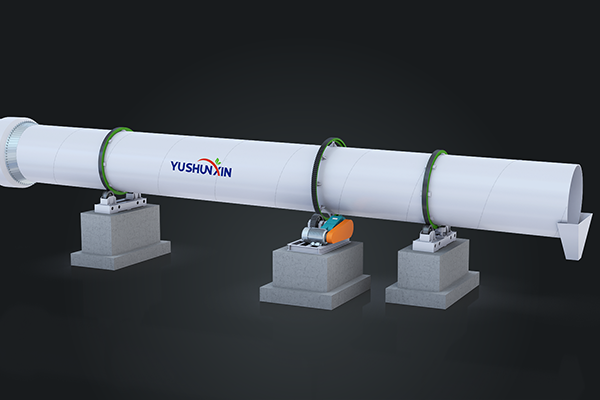

Rotary drum cooling machine

- Production capacity: 1~18 (subject)

- Type of equipment: Cool down

- Applicable materials: Organic fertilizers/slag/limestone/coal for power plants, etc.. e.

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from manufacturers: Yes

Rotary drum cooling machine, also known as a rotating drum cooler, usually used with a rotating dryer. It is suitable for lines for the production of combined fertilizers and lines for the production of organic fertilizers, and can cool granular fertilizers at a certain temperature. Chilled granular fertilizer will reach the optimal state, comfortable for your subsequent storage, Packaging, Transportation and implementation.

The rotational cooler consists of a cylinder, spiral plate, lifting plate, bunker and cooling pipelines. It has many advantages, such as a simple structure, Good stability, Reliable work, High adaptability and continuous work. It can also be used to cool other powdered or granular materials. It can serve materials with a temperature of 60 ° C to 80 ° C and reach a temperature of less than 40 ° C, When the material is unloaded.

When it is used with rotary dryer, He can remove dust and clean the exhaust gases of the material, increase cooling efficiency and efficiency of thermal energy, reduce complexity and increase performance. This can additionally remove moisture and reduce the temperature of the material. Play an important role in the production of fertilizers.

Why do you need a rotary cooler on your fertilizer production line?

The vast majority of organic fertilizer granulators use wet granulation technology. Granular fertilizers produced have a high water content and are not convenient for storage. Then you will have doubts, then I can dry a rotor dryer, Why do I need a rotary cooler?

This is due to that, that a small number of drops of liquid will remain on the surface of the dried granular fertilizer. If you keep it in this way, The granular fertilizer will stick together. A cooling machine can additionally dry these small drops. Besides, The temperature of the material, dried with a rotor dryer, Very high, And it is impossible to pack it directly. However, by cooling the cooler, the temperature of the granular fertilizer is reduced, And the material at this time can be good packed without agglomeration. The rotary cooler can also remove a little flying dust while cooling granular fertilizers.

How our rotary cooler reduces the temperature of your granular fertilizer?

Our rotational coolers provide Convection cooling for you. As soon as your material gets into bAraban from above, Your material turns, when a slightly inclined drum rotates. At this time, the lifting plate, mounted on the inner wall of the cooling cylinder, will continuously raise your materials. Then the material falls due to its own gravity, Forming a uniform stream.

With cold air, absorbed by exhaust smoke and material, Heat transfer is continuously carried out, thereby reducing the temperature of the material. The material cooled for you will flow out of the end of the equipment, and then go through the conveyor to the drum roar for the next processing stage.

What is the design and material of the rotational cooler, which we made for you?

You must understand, that knowledge of the material design of the device will help you better understand the device.

The bracket of our rotary cooler is cooked from a thick -power steel with an average carbon content and a channel steel, And the support videos, fixed on the bracket, Also made for you from high -quality anti -corrosion and wear -resistant materials, which significantly extends the service life of equipment.

Reducer frame of equipment is welded from high -quality channel steel. For the main engine and gearbox, reducer installed on the frame, We have accepted products for you, not requiring inspection under the ISO standard, And the quality is very reliable and guaranteed.

Gears, fixed on the case, made from high -tech wear -resistant materials. The wind belt is fixed on both sides of the machine, to maintain the entire body of the machine. The rotational cooler case is also cooked for you from high -quality plates of mid -carbon steel. For a lifting plate on the inner wall of the cooling cylinder, high -quality wear -resistant materials are used.

Why do we recommend that you buy our rotary cooler?

As a manufacturer of equipment for making fertilizers more 20 years, We have great production experience and stocks of professional knowledge. Rotary drum cooling machine, which we produce for you, has a high degree of mechanization and an excellent design and can perform continuous production for you. Material is required to cool the material, which reduces production costs. Our design of the angle of installation and distribution of lifting plates on the inner wall The cooler maximizes heat transfer between the material and cold air and increases the effectiveness of cooling.

Besides, Our rotational coolers are available in various models to satisfy your production needs of various performance. We also provide individual services, which you can configure at your discretion. Be it color, inscriptions or replacement of details, We can satisfy you.

What are the precautions for rotational cooler, which require your attention?

First, What should be noted, This is what, that when you need to turn off the equipment, You must first stop the heat flow, and then stop the flow of cold. Secondly, When you find, that the rotary cooler needs to be repaired, Before repair, you must wait for a reduction in the temperature of the equipment housing. If you need to clean the equipment, Be sure to follow the cleaning line procedures, To clean the carrier in the cooling cylinder. Otherwise, this may lead to some damage to the equipment.

If you have an intention to purchase a rotary cooler or equip a fertilizer production line, You can contact us to receive a commercial offer below. We always look forward to your call or email.