Russian clients are looking for solutions for the sustainable development of agriculture. They contacted us on the recommendation of a friend. Electronic letter clearly said, that they would like to purchase two different types of equipment for processing manure into granules. After deep communication and mutual understanding, Russian clients acquired drum and disk granulators. The use of feces has been successfully achieved. If you also need to purchase Equipment for the processing of manure, Contact us. We have a wide selection of various types of equipment for various purposes, To satisfy your diverse needs.

What are the needs of Russian customers for equipment for the processing of manure in granules?

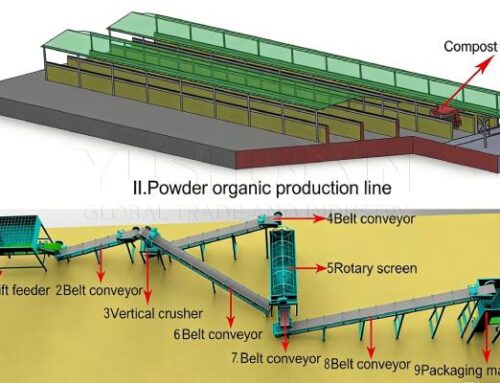

In the email sent to us, Russian clients spoke in detail about the difficulties, which they encountered, And about their expectations. The client noted, that the number of cattle and sheep in its livestock region continues to grow. The number of feces, produced daily, Reaches tens of tons. The client clearly indicated in an email letter, that he would like to purchase two different types of equipment for processing feces in granules. One machine can satisfy the needs of large -scale production, ensuring the effective processing of manure and the quick exit of the main organic fertilizer. Another should be able to produce high -quality granular fertilizers. Satisfy the needs of such high -tech markets, as growing fruits and vegetables.

Besides, The composition of the raw materials for the processing of customer feces is complicated, and there are differences in humidity, the size of particles and t. e. Therefore, there is hope, that the equipment will be able to adapt to raw materials for the processing of manure with various characteristics. But simply by adjusting the parameters of the process or equipment configuration, You can process mixtures of feces and others auxiliary materials In various proportions. Provide the flexibility of production. At the same time, equipment operation should be simple and convenient to use. Replacing the wear of the wear of the parts should be simple and convenient. The scope of work on daily maintenance should be as less as possible, to reduce labor and time.

The choice of equipment: The advantages of the drum granulator and a plate granulator complement each other.

Based on the needs of the client, indicated in the email, We conducted a professional analysis and technical comparison. We recommend two cars: drum granulator and disk granulator, which process feces in granules. Thanks to their characteristics, they perfectly meet the various production needs of customers.

Drum granulator: efficiency for large -scale production.

A rotating drum granulator Designed for large -scale production. Equipment is able to stably process 5-8 tons of dung raw materials per hour. The resulting granular fertilizer has an average strength and a rounded shape. Continuous and automated mode of production significantly increased the efficiency of production. Allows Russian consumers to quickly digest large volumes of fecal raw materials. Satisfy the huge market demand for basic organic fertilizers.

Disk granulator: The best choice for obtaining high -quality granules.

Disk granulator Designed for the production of high -quality granular fertilizers. Operators can flexibly control the size and shape of the particles, accurately adjusting disk speed, angle of inclination and dosage of the binder. Make high -quality granular fertilizers with a homogeneous particle size and smooth surface. Besides, The disk granulator has a simple control interface and low maintenance costs. Very well suited for scenarios of individual production of small batches.

Reviews of Russian customers!

After that, How these two equipment for processing manure into granules were put into operation, They quickly showed significant results. From the point of view of production efficiency, the drum granulator works in synergy with a disk granulator. The annual volume of manure processing at the customer exceeded 20 000 ton, and the annual production of granular fertilizers reached 8 000 ton. Compared to traditional serial models, efficiency is increased in almost 5 once.

Pellets in terms of product quality, produced by a drum granulator, meet the main needs of field cultures. High -quality granules, produced by a disk granulator, Successfully entered the market of elite fruit farming. Both types of products have successfully passed Russian certification of organic fertilizers.

If you also encounter the problem of utilization of agricultural waste, Contact us! Whether it is an equipment consultation, Design of technological solutions or questions and answers to technical application. We will provide you with comprehensive service, Using our professional knowledge and rich experience.