At the beginning 2025 year, a large poultry farm in the south of Russia sent a request through our company website. We hope to purchase completely automatic line for the production of organic fertilizers for processing chicken manure. Every year the customer grows about 500 000 laying hens. Huge amounts of chicken droppings were produced daily. Long-term storage not only polluted the environment, but also led to complaints about an unpleasant odor. The customer hopes use chicken manure as a resource for the production of organic fertilizer with high added value.

During a detailed discussion, the customer clearly outlined the following requirements:

- Performance: 5 tons/time

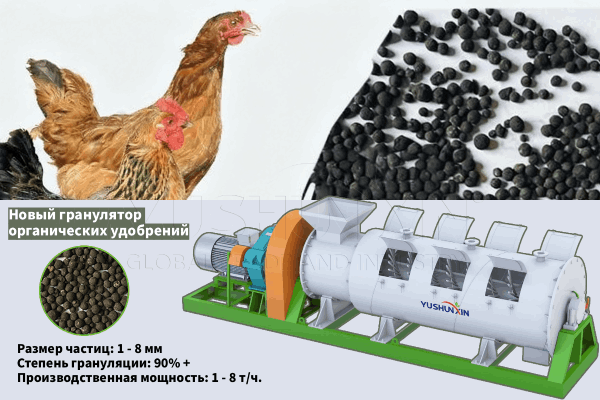

- Product shape: Granular organic fertilizer

- High degree of automation, ease of operation and maintenance

- Complies with Russian environmental standards

- Requires comprehensive line design and timely after-sales service

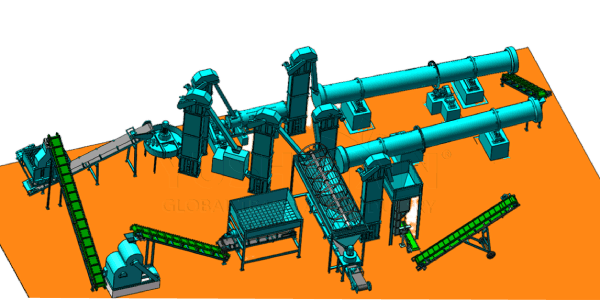

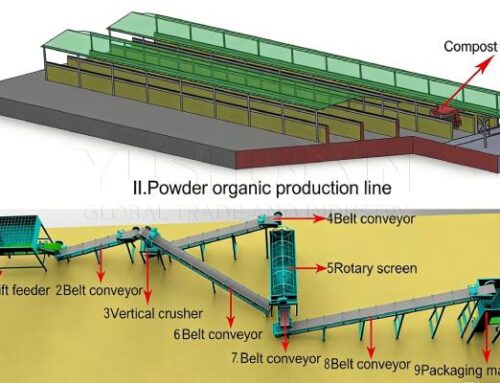

We provide Russian clients with designing solutions for processing chicken manure and setting up equipment.

Upon receiving the request, our sales and technical support specialists immediately contacted the customer, to determine site conditions and specific needs. In combination with customer production facilities, humidity of chicken manure and local climatic conditions. We have developed the following solution for our Russian client:

Progress and delivery of the chicken manure processing project for Russian customers.

After receiving our detailed technical proposal and site plan, the customer highly appreciated it. They even invited our engineers to a video conference to learn more about the principles and methods of operation of the equipment. After two rounds of detailed technical discussions, the customer ultimately signed the sales contract. An automatic line for the production of organic fertilizers from chicken manure was selected with a productivity 5 subject.

In mid-April, our company sent engineers to Russia for on-site installation and commissioning. All equipment was installed and working stably in just 15 days. During the commissioning period, the customer expressed great satisfaction with the quality of the finished organic fertilizer granules and the improvement in air quality within the plant.

Этот комплект оборудования для переработки куриного помета производительностью 5 тонн/час специально разработан для российских заказчиков. Принимая во внимание эффективность, морозостойкость, интеллект и защиту окружающей среды. Она помогает российским заказчикам достичь своих целей по сокращению объёмов, безопасной переработке и повторному использованию отходов животноводства. Если у вас есть какие-либо требования к индивидуальным решениям, детальной конфигурации оборудования и техническим параметрам или проведению инспекций на месте, Please, Contact us. Мы искренне предоставим Вам высококачественное оборудование и услуги!