Bentonite filler for a cat's toilet, being an indispensable product for families, who own cats, is in consistently high demand on the market. It has excellent moisture absorption and clumping properties, low cost of raw materials and streamlined production processes. This project boasts a short payback period and significant profits. It represents a very promising investment opportunity for you. If you are looking for a cost-effective startup project, production of bentonite cat litter, Undoubtedly, will be the best choice. Looking for equipment for the production of cat litter, tailored to your production capacity? Contact us at any time for consultation and individual selection.

How we build a high quality bentonite cat litter production line for you?

In a competitive market for high quality cat litter, the availability of an effective, stable and intelligent bentonite filler production line is crucial. This allows for high purity, excellent clumping properties and high economic efficiency in the production of cat litter. Therefore, we pay special attention to careful control of the production process of bentonite cat litter. How can we help you create high quality bentonite cat litter?, using scientific methods and strict process control?

Pre-treatment of raw materials for bentonite cat litter.

- Pre -processing of raw materials: natural Bentonite ore sodium based feed into jaw crusher for coarse crushing. It is then ground into a fine powder of particle size 200-300 using Raymond mill. At the same time, a vibrating sieve is used to remove impurities, ensuring the purity of raw materials more 98%. This lays the foundation for subsequent granulation.

- Mixing and Stirring: Bentonite powder and auxiliary materials are proportionally added to the twin-shaft mixer, such as sawdust, cellulose and fragrance, according to the selected recipe. Add required amount of water as binder. Mix for 10–15 minutes until a homogeneous free-flowing mass is obtained.. Humidity should be controlled within the range 18% to 22%.

Granulation Process of Bentonite Cat Litter.

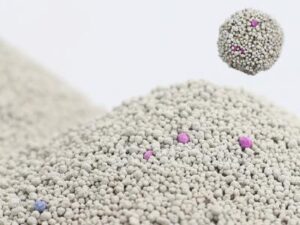

- Granulation and molding: The mixed material is fed into a disc granulator or rotary drum granulator. Granulation is carried out by rotating the equipment. The particle diameter can be adjusted ranging from 2 to 5 mm. During the granulation process, it is necessary to control the compactness of particles in real time, to avoid the appearance of loose particles.

- Drying and dehydration: The formed granules enter the drum dryer. Drying is carried out by circulating hot air. Drying temperature should be 120–150 °C, and time – 20–30 minutes. Reduce the moisture content of the pellets to less than 10%, to ensure stable moisture absorption and clumping properties of cat litter.

Post-processing of bentonite cat litter granules.

- Sifting and sorting: The granules are screened on a drum screen to separate low-quality fine powder and large particles. Fine powder can be returned to the mixer for reuse. Large particles are crushed and re-granulated. Pellets, relevant to the requirements, move to the next stage, ensuring efficient use of resources. Reducing production costs.

- Packaging and warehousing: High-quality cat litter is packaged in 2 kg, 5 kg and 10 kg by automatic packing machine. Equipped with weighing and detection system to ensure accurate measurements. After packaging, store in dry, well ventilated area, to prevent moisture absorption and deterioration.

What budget do you need to build a cat litter production line??

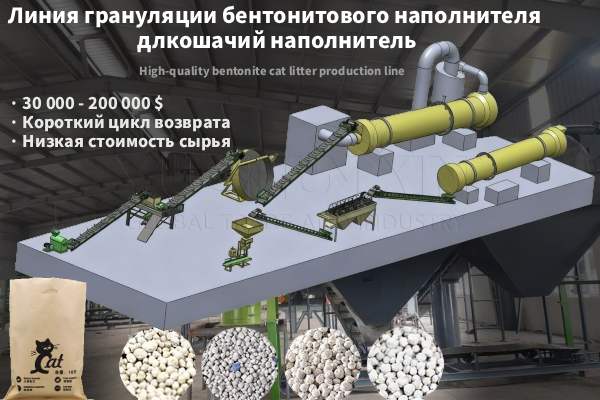

Investment in equipment for a cat litter production line depends on such factors, like production capacity and level of automation. Different configurations result in significant price differences. Below are three different equipment configurations and investment recommendations for bentonite cat litter production lines.:

Small production line for bentonite cat litter with a capacity of 0.5–1 tons per hour.

- Main equipment: Small jaw crusher (5000–$8000. USA). Raymond mini mill (8000–$12,000. USA). Small twin shaft mixer (4000–$6000. USA). Small disc granulator (3000–$5000. USA). Rotary drum drying machine (5000–12 000 Doll. USA). Small Vibrating Screen (2000–$3000). Semi-automatic packaging machine (5000–$10,000. USA). The total investment for a complete set of equipment will be approx. 30 000–50 000 US dollars.

- Suitable for: start-ups and small workshops. Annual output is about 3000–6000 tons.

Medium Capacity Cat Litter Production Line 1-2 subject.

- Equipment configuration: Raymond Medium Capacity Mill (12 000–18 000 Doll. USA). Twarge mixer average productivity (8 000–12 000 Doll. USA). Standard Rotary Drum Granulator (15 000–25 000 Doll. USA). Medium size rotary dryer (10 000–15 000 Doll. USA). Three stage drum screen (5 000–8 000 Doll. USA). Semi-automatic packaging machine (3 000–5 000 Doll. USA). Basic dust collection equipment is also required (4 000–7 000 Doll. USA) for dust pollution control. Total investment is approx. 50 000–100 000 Doll. USA.

- Suitable for: domestic market with planned regional distribution. Annual production capacity is approx. 8 000–15 000 ton.

3–8 t/h Large scale bentonite cat litter production line.

- Automated hardware configuration: Large size crusher (15 000–25 000 Doll. USA). High performance mill Raymond (20 000–30 000 Doll. USA). Single shafts mixer (15 000–25 000 Doll. USA). Large Size Drum Granulator (25 000–40 000 Doll. USA). Large rotary dryer (18 000–28 000 Doll. USA). Rotary drum screening system (0,8–1.2 million. Doll. USA). Fully automatic packaging line (12 000–18 000 Doll. USA). Simple control system (7 000–12 000 Doll. USA) for automated monitoring. General investments: about 100 000–200 000 Doll. USA.

- Suitable for: large scale production and export business. Annual production capacity is approximately from 30 000 to 50 000 ton.

Besides, When investing in equipment, transport costs must be taken into account, installation and commissioning costs, as well as the costs of plant reconstruction. We can develop cost-effective equipment configuration solutions to suit your investment budget and production capacity requirements. Help you reduce the pressure of initial investment.

Which granulator is best for producing bentonite cat litter??

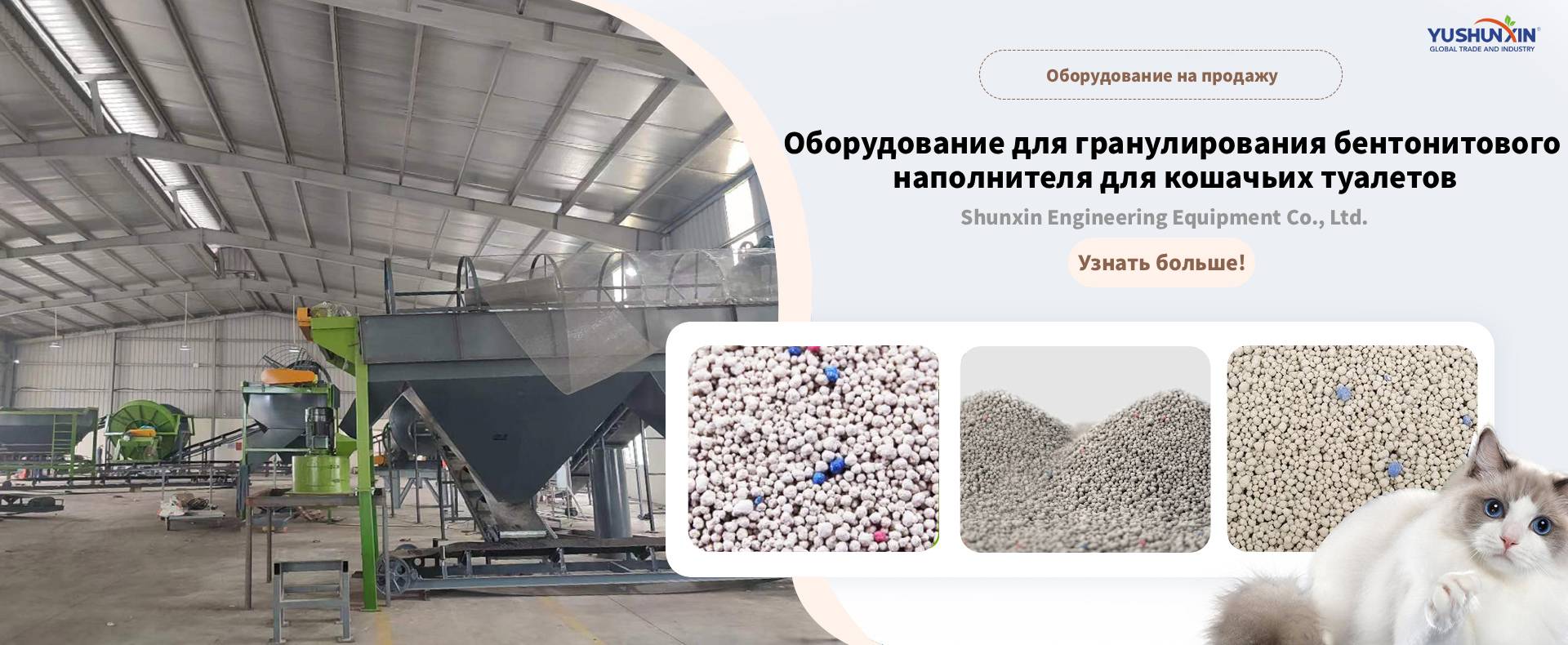

The choice of granulation equipment directly determines the uniformity of product granules, agglomeration efficiency and productivity. Shunxin company, professional manufacturer granulation equipment. Based on our experience with thousands of production lines, We have prepared for you some precise recommendations for choosing:

Disc bentonite granulator for cat litter

Disk granulator: Ideal for small and medium enterprises. This equipment uses a rotating disc to granulate raw materials. The size of the particles (diameter 2–5 mm) and the shape can be flexibly adjusted according to the positioning of different brands' products. The equipment is easy to operate and requires low maintenance costs. Hourly productivity can reach 0.2–6 tons. Suitable for investors with a limited initial investment budget, focused on regional markets.

Drum bentonite granulator for cat litter

Drum granulator: Basic equipment for large scale production. It uses a continuous granulation process. The material gradually agglomerates into granules due to constant collision and friction inside the drum, achieving uniform granulation. The particle size can be adjusted using the following parameters, like the speed of the drum, The angle of inclination, material humidity and feeding speed. The maximum hourly productivity can reach 30 ton. This allows us to meet production capacity needs for national distribution and export orders..

Besides, we can also provide suitable coating equipment, Meeting production needs of high quality bentonite cat litter. Increase the added value of your products, spraying antibacterial agents or natural flavors onto the surface of the granules. If you have relevant needs, Contact us. Get more information and pricing on cat litter pelleting equipment and related processes.

Below are several recipes for the production of filler for cat toilets made of bentonite clay. For your reference and brief understanding.

- Sodium bentonite: 60%

- Sawdust: 20%

- Pulp: 20%

- Binder: water

This filler for a cat toilet does not contain other chemical ingredients and is safe for cats and the environment.

Sodium bentonite powder: 98%-100%

Sodium bentonite powder: 98%-100%- Calcinated soda: 2%

- Granular flavor: 0,5 %.

(You need to purchase granular spices. Mix them with a ready -made filler for a cat toilet, and then pack it.) Spices are selected from one or more varieties: if, Sandals, carnation, Pachuli and Lavender. First you can conduct market research, to see, What aromas are more popular.

- Green bamboo powder: 30%-35%

- Green tea powder: 20%-25%

- Activated carbon powder: 30%-35%

- Sodium bentonite powder: 10%-15%

At the same time, you can also add Chinese herbs, Such as cloves, mint, cork, Timian, Camellia and T. e. They can increase the bactericidal ability and aroma of bentonite filler for cat toilets.

Is it profitable to produce bentonite fillers for cat toilets now?

It's clear, that the market price of bentonite raw materials is about 19 US dollars per ton. The market price of a cat toilet is about 70 US dollars per ton. Minus a number of costs, profit per ton of bentonite filler for cat toilets will also be about 28 US dollars.

Besides, Pets consumption in various countries is also growing. The market demand for fillers for cat toilets is high, And the market capacity is great. Thus, Based on these circumstances, current investments in the production of bentonite fillers for cats are very profitable.

We not only supply individual devices, but we also offer you comprehensive services. This includes everything: from plant planning, equipment selection, debugging formulas before staff training. The cost of a complete cat litter production line in our factory ranges from 30 000 to 200 000 US dollars. A specific quote will be tailored to your production needs and process configuration.. If you are interested in investing in a cat litter production project, contact us for detailed information about equipment and production line. We provide you with customized solutions and comprehensive practical support, that will help you effectively enter the market and take advantage of business opportunities!