After that, How granular fertilizer is produced, only a very small part of it has the opportunity to be immediately sold. Most granular fertilizers will be stacked and transported for a long time. If granular fertilizer is produced at the time of sowing by farmers, it will be sold and used soon. But if it was produced in the off-season, it can even lie in warehouses or stores for up to six months. Prolonged stacking will cause the granular fertilizer to re-wet and agglomerate. The occurrence of this phenomenon will reduce the quality of your granular fertilizer, which will make it difficult to sell.

How to avoid moisture and caking phenomenon of granular fertilizer due to long-term storage?

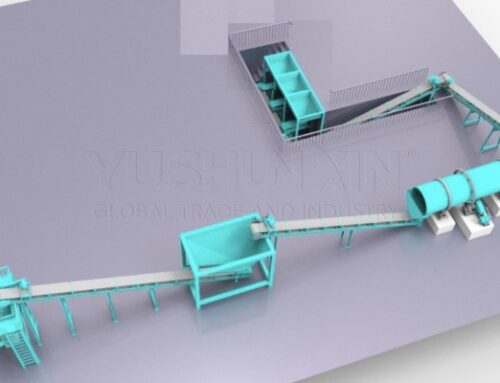

To avoid this phenomenon, Most granular fertilizer manufacturers add a rotor to the production process. coating machine. This equipment is usually located after drum dryer And drum cooler, and also drum screen. After that, How qualified granular fertilizer is screened out drum screening machine, The coating process is carried out by a rotary coating machine.

Rotary coating machine uses special liquid raw material or atomization process combined with solid powder. Form protective film on the surface of your granular fertilizer, to isolate it from outside air. This can avoid occurrence salting out and moisture absorption.

What benefits can granular fertilizer coating provide to your products??

In addition to preventing moisture and caking, which often occur in some granular fertilizers, coating fertilizer granules can also bring you many benefits.

Coating turns your granular fertilizer into a slow-release fertilizer. Slow-release fertilizers are also called slow-release fertilizers or controlled-release fertilizers. The rate of nutrient release in slow release fertilizers can be controlled to a certain extent, allowing cultures to continuously absorb and use them. Using slow-release fertilizers can allow farmers to reduce the amount of fertilizer needed and reduce planting costs for farmers. Besides, the use of slow-release fertilizers can increase the resistance of crops to diseases and lodging, and also increase productivity by more than five times. Thus, slow release fertilizer is popular with many farmers and has a huge market.

Protective film, formed by a rotary fertilizer surface coating machine, can make the surface of granular fertilizer brighter and smoother. Certain micronutrients can also be properly added to the barrier film formulation to enhance the effectiveness of your granular fertilizer.

What is the working principle of granular fertilizer coating machine?

It's important to understand, how the equipment works. The rotary coating machine is driven by the main motor, which drives the belt and pulley. It is transmitted to the drive shaft through gearbox. Divide in half gear, mounted on drive shaft, engages with a large ring gear, fixed to the machine body, and works in reverse rotation mode. The material is fed from the loading end and can be discharged from the discharge end after mixing and coating inside the cylinder, to ensure continuous production operations for you.