A stove for carbonization helps transform various organic materials into charcoal.

Carbonization furnace

- Type of equipment: Auxiliary equipment

- Applicable materials: Wood, Rice husk, Coconut shell, branches, roots, peel, logs, Korovy manure and t. e.

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from the manufacturer: Yes

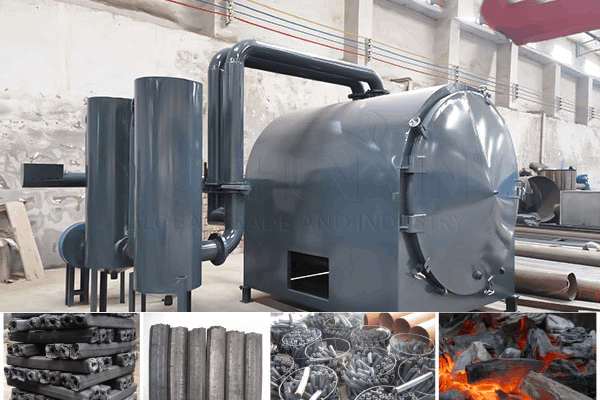

Carbonization furnace is a device, used to convert various organic materials into charcoal. It performs biomass pyrolysis in conditions of high temperature and lack of oxygen, turning waste into a valuable biode. The furnace can process various types of biomass, including wood, branches, bark, gamble, sawdust, Coconut shell, straw, I am a cheerful sheluh, Bamboo chips and fruit shell. It is the necessary equipment for the production of charcoal, fertilizers based on charcoal and other products. Shunxin company can provide you with various types of carbonization furnaces, which will satisfy your various production needs. If you have interest or questions about carbonization furnaces, Contact us to get additional information.

Shunxin offers three different types of carbonization furnaces, corresponding to your production needs.

Shunxin seeks to provide customers with various and effective solutions in the field of carbonization to meet the production needs of various industries. Below are three different types of carbonization furnaces, which we offer. Each of them has unique advantages and features:

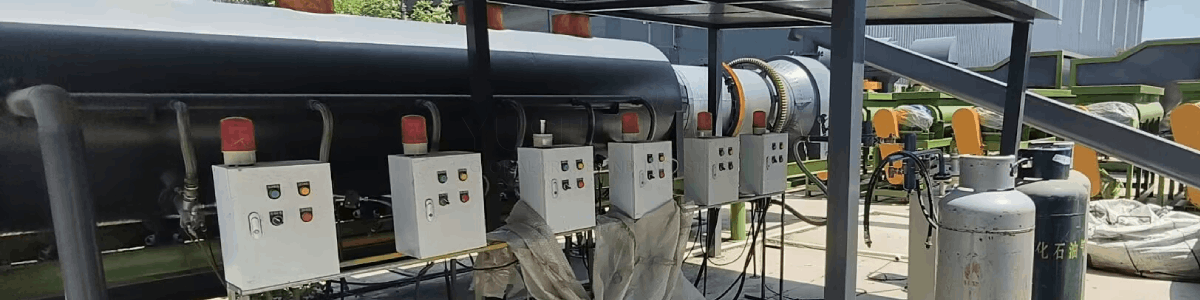

Horizontal stove for carbonization:

- Performance: 300-6000 kg/h.

- Carbonization time: 11–14 hours/Party.

- Characteristics: Horizontal carbonization furnaces are suitable for dry distillation or carbonization processes in the air flow. It is able to effectively decompose wood and other organic materials in anaerobic conditions.

- Advantages: Simple design and ease of operation. Flexible configurations allow you to satisfy a variety of production needs. Especially suitable for small and medium -sized enterprises with cyclic production.

Lifting stove for carbonization:

- Processing performance: 1–1.5 tons/hour.

- Carbonization time: 8–16 hours/Party.

- Characteristics: Uses carbonization technology with hot air circulation to ensure effective heat transfer and uniform carbonization. Effectively increases carbon content and reduces the cycle of carbonization.

- Advantages: Flexibility, sufficient to satisfy the requirements for continuity and stability of large -scale production. Suitable for use in industries, requiring high efficiency and reliability.

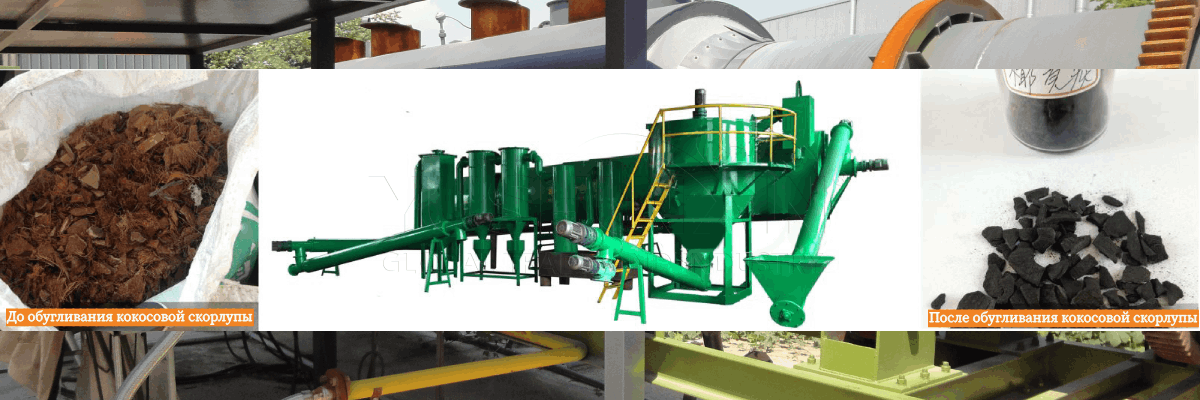

Bake of continuous carbonization:

- Performance: 500-5000 kg/h.

- Carbonization time: 24 hours of continuous carbonization.

- Peculiarities: Support for round -the -clock uninterrupted work. Implement a continuous feed, Continuous carbonization and continuous output of the process of production. Can automatically collect by -products, formed in the production process.

- Advantages: Ideal for large -scale continuous production. Suitable for large enterprises or applications, requiring continuous production. High performance for low energy consumption.

Each type of carbonization furnace is carefully designed to ensure optimal performance and reliability. Regardless of your production needs, Shunxin can offer you the most suitable solution for a carbonization furnace. Help you succeed in market competition. Contact us to receive additional information and professional consultation.

What materials can be carbonized using carbonization equipment?

Carbonization stoves can process various types of biomasses. Due to its versatility, the carbonization furnace is ideal for processing agricultural and industrial waste. This will help you effectively reduce production costs and achieve effective re -use of waste. After carbonization, these materials can be transformed into such products, Like coal powder, charcoal, Activated carbon, or processed for the production of carbon fertilizers. To common types of biomass waste, which can be carbonized, Relate:

What temperature of carbonization can be achieved in our stove for carbonization?

Temperature control is crucial in the process of carbonization. Different types of carbonization furnaces have different upper temperatures.

- In horizontal carbonization furnaces, the temperature in the furnace rises to 160–280 ° C at the initial stage of carbonization. This triggers the reactions of thermal decomposition in wood material, which leads to a change in its composition. At the stage of carbonization, the temperature can reach 300–650 °C.

- In the process of carbonization in the lifting furnace, the temperature can reach 600℃. Combustible gases can form. These gases circulate and heat up inside porous pipes. This eliminates you the need for fuel supply after its exhaustion.

- In the process of carbonization, the temperature inside the furnace can achieve 350-500 ℃. The temperature in the carbonization pipeline is 500–700 °C. The fuel uses natural and liquefied hydrocarbon gas, which allows you to accurately and flexibly adjust the temperature. Adaptation to the requirements of carbonization of various materials.

What are the requirements for the size of the loaded material for our carbonization furnaces?

Different stoves for carbonization present different requirements for the size of the loaded material. However, usually, To ensure a stable and uniform process of carbonization, the size of the loaded material must be relatively homogeneous. Excessive size fluctuations can lead to incomplete carbonization or decrease in efficiency. What size of the source material is necessary to achieve the best effect of carbonization when using our equipment for carbonization?

For horizontal and ceiling furnaces of carbonization, the size of the loaded material should be less 30 cm to ensure a sufficient pyrolysis process. The optimal size of the loaded material for the continuous carbonization furnace is less 10 cm, which can increase the efficiency and uniformity of carbonization. If your material is too large, We have wood -bearing, which will help you grind it to a homogeneous size.

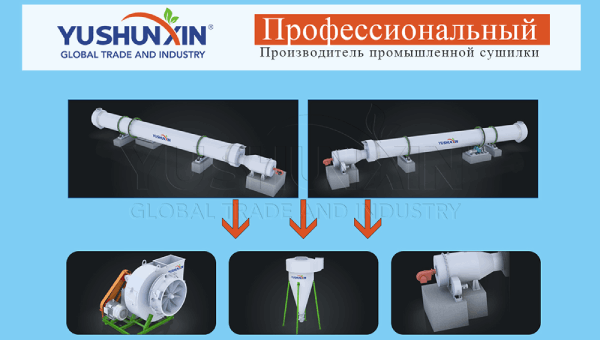

Does the moisture content of the material affect the effect of carbonization?

Certainly, This will have an impact. Material moisture is one of the key factors, affecting the effectiveness of carbonization. To achieve the best effect of carbonization, we recommend maintaining the moisture content of the material below 20%. Excess humidity not only increases energy consumption, but can also increase the time of carbonization and reduce the quality.

Therefore, sufficient preliminary drying of the material before carbonization is an important step to achieve effective carbonization. Rotary drum drying machine helps reduce the humidity. Has two drying modes: Drying by stream and drying in a gasket, performance 1-18 subject. The correct selection of dryers and the drying method will help your carbonization stoves achieve the best result of carbonization.

How to choose a suitable stove of carbonization for your needs?

The choice of the most suitable carbonization furnace for your use requires a comprehensive consideration of many factors. For example, The scale of production, Characteristics of materials, The level of automation of equipment and energy consumption and t. e. Shunxin provides professional consulting services, To help you choose the optimal equipment solution taking into account your specific needs. Our expert team will provide individual recommendations, based on your production requirements and budget. Ensure the maximum return on your investment. Please, Send us by e -mail information about your situation and other information, So that we can better develop a plan for you.

Shunxin seeks to provide customers with high -quality products and services in the field of carbonization furnaces. If you want to know more about carbonization furnaces or get a personal advice on choosing equipment, Contact us. We are looking forward to cooperation with you.