Granular fertilizers are less susceptible to moisture and cave, than powder, which facilitates long -distance transportation and long -term storage. Shunxin fertilizer granulation equipment will help you get high -quality fertilizer granules.

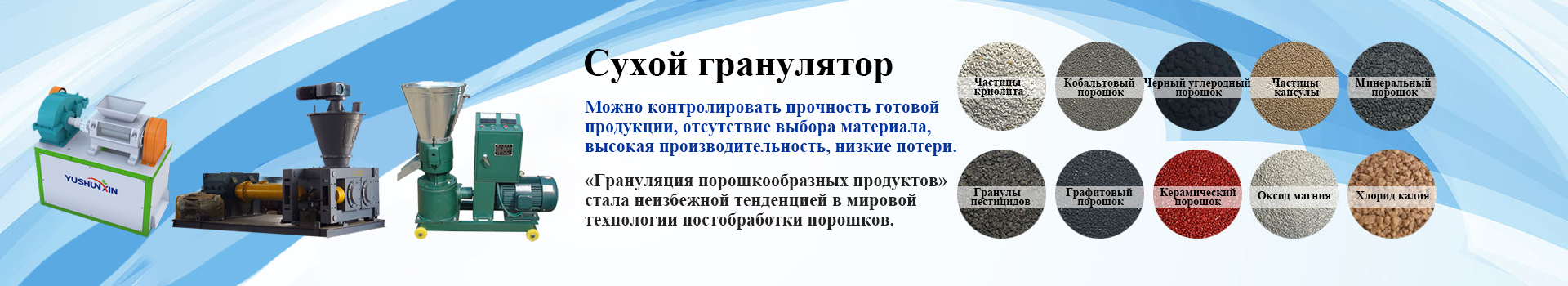

What equipment for dry granulations are available in shunxin?

Dry granulation technology is a method of physical pressing of powdered materials in granules. Compared to traditional wet granulation, dry granulation does not require the use of any binding substances or additives. The drying process is also not required. This significantly saves energy consumption. And reduces potential problems of pollution.

The key advantages of dry granulators are their high efficiency and environmental friendliness. This technology improves the fertility of powder. Improve the physical properties of the final product, Such as hardness, Density and solubility. Besides, The process of dry granulation reduces the risk of chemical reactions and microbial contamination, which may arise in wet conditions. This is especially important for materials, sensitive to moisture or solvents.

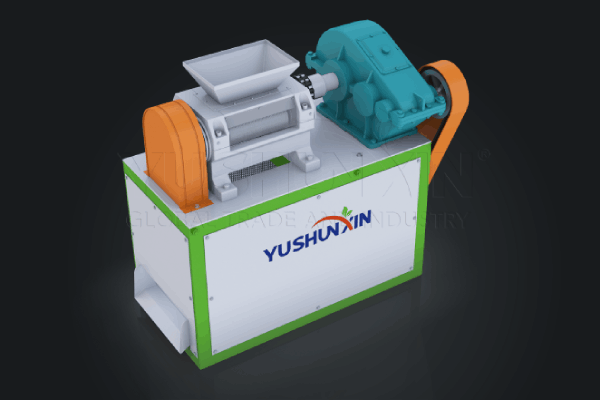

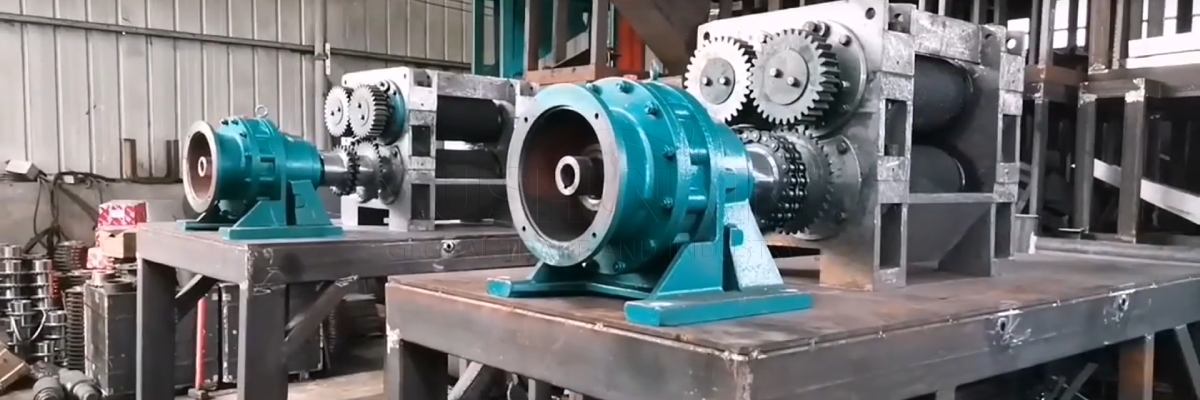

Robite granulator

The principle of operation of the roller granulator is the use of two relatively rotating videos to provide pressure between the rollers. The material is pressed in sheets. Then it is granular through subsequent cutting processes, crushing or sifting. The surface of these rolls can have a different texture and a pattern for obtaining particles with certain characteristics.

Two-layer-roller granulator

Two -layer roller granulator is a new type of granulation equipment, characterized by high efficiency and energy conservation. Equipment is equipped with two vapors of rollers. Mechanical pressure presses powder materials in spherical or elliptical granules, providing continuous automated work. The two -deck design not only increases performance, but also optimizes the distribution of material and the effectiveness of granulation, Effectively reducing energy consumption. Equipment is simply in operation and maintenance, and the finished product is characterized by uniform size and high strength.

Granulator device with a flat matrix

A granulator with a flat matrix is equipment, usually used in the field of energy production from biomass. He transforms the raw materials of biomass (For example, sawdust, straw, gamble, feed, etc.. e in.) to pellets by pressing. This type of granulator is especially suitable for small -scale production and home use. Because it has a simple design, simplicity of operation and relatively low maintenance costs.

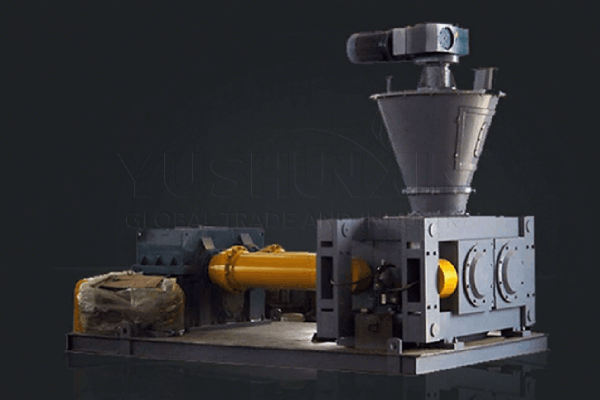

Screw extrusion granulator

The granulator of potassium fertilizers can compress powder potassium fertilizers with a moisture content less 5% in flakes or blocks. Then it is divided into entire particles using a crushing device. In the process of rolling, the actual density of the material may increase in 1,5-3 times. To satisfy your requirements for particle strength. Particle strength can also be freely adjusted in accordance with various materials.

We strive to constantly introduce innovations and optimize our technology of dry granulation. To provide you more effective, more reliable and more environmentally friendly solutions for the production of fertilizers. We believe, that working with us, Your production process will become more energy -saving and effective. At the same time, Fertilizers will also be more popular in the market.

What granulation equipment in Shunxin uses technology wet granulation?

Wet granulation methods usually include the addition of water or other liquids to powdered ingredients. High -quality granular fertilizers are produced by a number of technological stages, Such as mixing, Grauling and drying. Our equipment for wet granulation has an advanced structure. The possibility of accurate monitoring the amount of added to the wetting agent. Make sure, that the ingredients are thoroughly mixed and glued, To form homogeneous wet granules.

Wet granulation not only improves the physical properties of raw materials, but also optimizes the recipe of fertilizers. For example, Add microelements, bioactive substances or other functional additives. Increase fertilizer added. Each type of equipment for the production of granules is carefully developed and optimized to satisfy various types and scale of production needs.

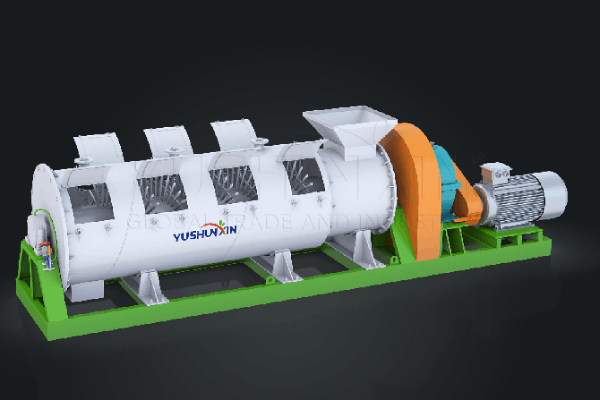

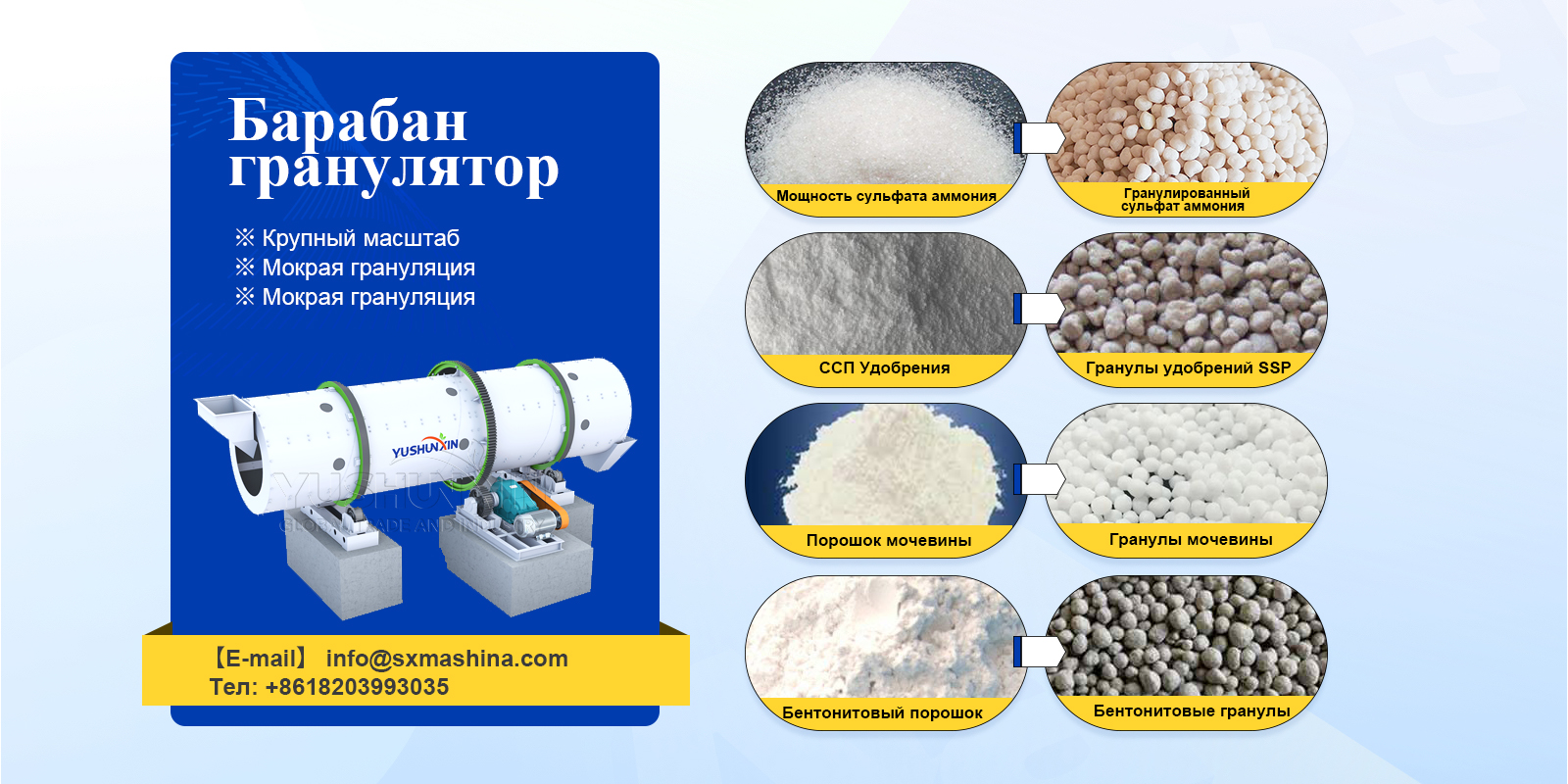

Drum granulator

A drum granulator is equipment, appliances widely used in the industry. It is suitable for large -scale production of cold and hot complex fertilizers of high, medium and low concentration. The device has a rotating cylinder with a large inclination. Due to the special internal structure and suitable speed of rotation. Materials can be folded and rounded in a barrel. Form the desired granules.

Disc granulator

Disk granulator is widely used equipment for granular. Widely used in fertilizer industry, as well as when processing pellets in pharmaceutical, chemical, feed and other industries. It is mainly suitable for small -scale production and can process powder raw materials into spherical particles. The disk granulator has a simple design and is easy to operate. This is one of the perfect devices for preparing granules.

Granulator of organic fertilizers

Organic fertilizer granulator is a device, specially used for forming raw materials of organic fertilizers into granules. The use of mechanical stirring power of high -speed rotation and arising from aerodynamic force. Small powder materials can be continuously mixed, Granulate, spheroidal and compact in the car. The equipment has a high amount of combustion of particles, and ready -made fertilizer particles, produced for you, They have a beautiful look.

Rotary drum churning granulator

This is a dual granulator. The design combines the characteristics of the eardrum and granulator of organic fertilizers. It can process chemical raw materials for the production of complex fertilizers, as well as process organic materials for the production of organic fertilizers. Production capacity 5-8t/h. The particles produced by him have a high coming speed, more beautiful and save energy for you.

In addition to the supply of equipment, We also provide a full range of technical support and services. Including technological design, Installation of equipment, commissioning, Operation training and subsequent maintenance and modernization. Make sure, that you can start and maintain production without problems. We strive for constant technological innovation and improvement. Give fertilizers to manufacturers around the world effective, environmentally friendly and economical solutions for wet granulation.

What equipment will help you increase the value of the value of the finished granules?

Rounding machine for granules. This is a type of equipment, specially used for processing particles of irregular shape in round particles. Under the influence of the rotation of the cylinder and friction, the particles gradually become smoother and dense during movement. Our rounding machine granules is compact, simple in operation and highly effective. It is especially suitable for rounding the granules after granulation. It is widely used in organic fertilizers, complex fertilizers, medicine, food, fodder, chemical industry and other areas. It significantly improves the appearance and fluidity of granules. The finished product has a uniform particle size, smooth and smooth surface, which improves the appearance of the product, Quality and competitiveness in the market.

How much time will you take to compost the party using our equipment for composting?

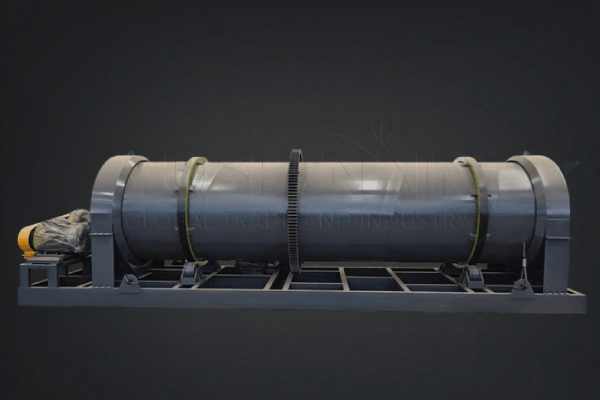

With damp granulum, the resulting granular fertilizers often contain a certain amount of water and it is not easy to store them. Therefore, these granular fertilizers must be treated by drying and cooling. Our optimized Drying process Increases energy efficiency. Reduce production costs and maintain stability and product quality. Cooling process helps stabilize the physical and chemical properties of particles. Ensure the convenience of your subsequent packaging, storage and transportation.

How to make fertilizer particles, which you produce, round and full?

Pellets, produced equipment for the production of granules, may comply with the requirements in the form of most fertilizers. If you have high requirements for the appearance of fertilizers, You will need A machine for rounding organic fertilizers. He can polish and form particles.

A machine for rounding organic fertilizers is an equipment for molding granules, specially used in the production of organic fertilizers. The main function is the mechanical polishing of the initially formed particles of irregular shape to round spherical particles. Improve the quality of the appearance and commercial value of particles. Machines of this type are usually located in the rear of the line for the production of organic fertilizers.

The principle of operation of the machine for rounding of organic fertilizers is usually based on a rotating mechanism with a polishing disk. The polishing disk rotates at high speed during the operation of the machine. The material is rubbed and rolled inside the polishing disk, Constantly colliding and contracting, gradually becomes smooth and homogeneous. This process not only improves the appearance of granules, but also helps to increase their strength for compression and stability, which simplifies storage and transportation.

Why choose the equipment for composting fertilizers Shunxin? —— Three reasons

Advanced technology

Our factory has been introduced modern large and medium -sized gold equipment, corresponding to international standards. Constantly optimize the design of equipment for the production of granules. Make it smarter, More effective and environmentally friendly.

20+ years of experience

Shunxin has more than 20 years of experience in the production of equipment for granular fertilizers. No matter, what raw materials you have, We can offer you a solution for granulation, which is suitable for you.

Lifelong after -sales service

We guarantee you. No matter, How many years have you been using pellet equipment you purchased. If there is a problem, We can provide you with a decision within 48 hours.