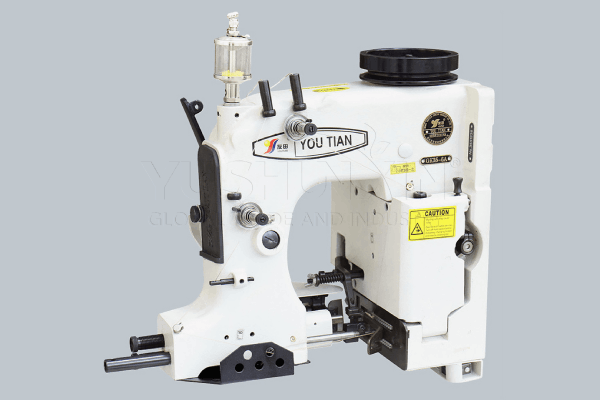

The GK35 bag

- Type of equipment: Auxiliary equipment

- Applicable materials: Organic fertilizers, Complex fertilizers, NPK fertilizers, Complex fertilizer, stern, mines, coal, ports, etc.. e.

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from the manufacturer: Yes

The GK35 bag of the GK35 series is highly effective equipment, designed to meet the needs of packaging in various sectors. Thanks to strong design and excellent sewing performance, Shunxin cars The GK35 series easily cope with the task of sealing packages from various materials, including bags, Paper and plastic bags. The compact design not only saves place, but also ensures the flexibility of use in various production conditions. Simplicity of operation and low service costs make a GK35 bag of the GK35 series with an ideal choice to increase production efficiency. Be it agriculture, chemical or food industry, Our bag -sailing machines of the GK35 series will provide reliable packaging solutions. If you want to buy a bagser car, Contact us.

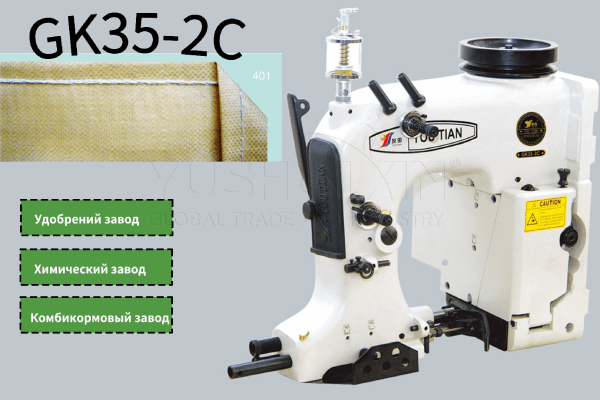

Two-Nikniper Meshopian machine of the GK35-2C/2CF series.

Two-Niknight machine for sewing bags GK35-2C.

This bag for suturing bags uses manual control to start and stop, as well as a built -in knife for trimming threads. She is safe, reliable and easy to operate. For key details, we use high -quality alloy steel and wear -resistant copper alloys. The machine has a long service life and is easy to maintain.

Two-Niknight machine for sewing bags GK35-2CF.

This bags -polling machine is a new type of bags -sized machine with the opposite direction of sewing, designed on the basis of the GK35-2C bag. It can be used in conjunction with the GK35-2C bagser machine for simultaneously suturing the holes of the bag on both sides.

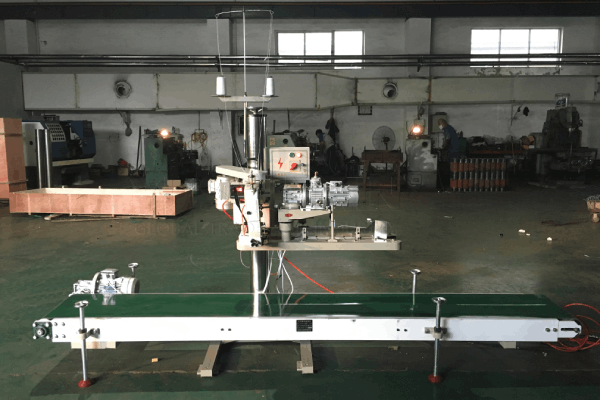

The principle of operation of a two-nick-button bag of the GK35-2C/2CF series:

Install a bagser car on the conveyor. After the power is turned on, the conveyor begins to work and moves the bag filled with the material. When the bag reaches the crush foot of the sewing machine, Click on the pedal, To run it. When sewing each bag, press on the corner knife for cutting wire braid. Then release the pedal, to stop the sewing machine.

Two-minute sewing machine of the GK35-6A/6AF series.

Two-minute sewing machine for sealing the GK35-6A bags.

This model is a fully automatic sewing machine for sealing bags. It is equipped with a knife structure. Under the influence of the cylinder, the upper and lower knives interact to complete the cutting process. The cutting process is more reliable, and the car can simultaneously cut fortress paper, etc..

Two-Nikniper sewing machine for sealing the GK35-6AF bags.

This model of a sewing machine for sealing bags is a new type of bags -sized machine with a reverse movement, designed on the basis of the GK35-6A bag. The machine can operate together with a positive sewing machine GK35-6A for simultaneously suturing holes of bags on both sides on one column.

The principle of operation of the two-native bag of the GK35-6A/6AF series:

Install a bagser car on the conveyor. When the woven bag filled with materials reaches the position 10 cm from the car on the suturing of the inner bag, The machine automatically begins to sew the neck of the bag under the control of the light switch. After stitching each bag, the cutter automatically cuts off the braids of the thread, and the sewing machine for bags automatically stops.

GK35-8A Double-heiginal automatic sewing machine for sealing bags.

This model of a bagser car is equipped with a photoelectric sensor, pneumatic device trimming and controller. Launching and stopping the car, as well as automatic trimming are automatically controlled by a photoelectric sensor and controller. The design with a double straight needle and a double curved needle provides airtight suturing of bags. Double I needle four -nepual structure allows you to make two stitches at the same time, which provides strength and reliability. Wear -resistant details, high sewing speed and low noise level.

The principle of operation of the double-heiginal automatic bag of the GK35-8A:

The bag is installed on the conveyor. When the woven bag, filled with material, reaches ten centimeters inside the machine, under the control of a photoelectric sensor, the machine automatically begins to sew the hole of the bag. After stitching each bag, the cutter automatically cuts off the braids of the thread, and the sewing machine for bags automatically stops.

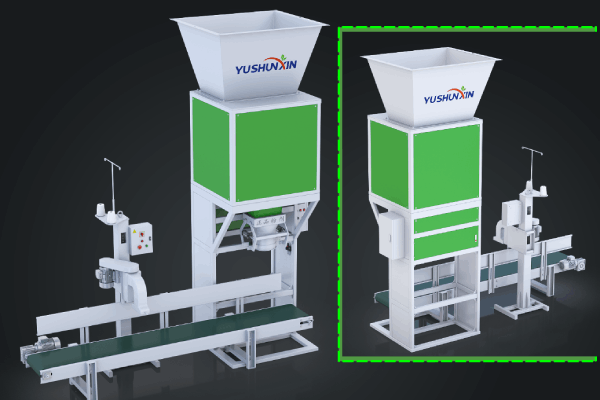

For which industries, our bags -polling machines are suitable for you?

Widely used in grain, chemical, Complex, mining, coal, Port and other industries. Used to seal plastic woven bags, Meshkov, tissue bags, paper bags and other packaging materials, filled with powdered and granular materials. If your materials must be transported to long distances or exported, Our bags -sized machine will become an indispensable device for you. We can mount it for you on electronic quantitative packaging weights different types for transportation and sealing packages. Certainly, We can also provide you with various models of electronic quantitative packaging weights, conveyors and other equipment. If you have any needs, Please, Contact us.

Shunxin seeks to provide customers with effective, Reliable and economical solutions for packaging. We meet the most diverse needs of various industries. Do you need a car for suturing bags, Completely automatic palletizer, electronic quantitative packaging scales or conveyor. We can provide you with everything you need. Make sure, that you will find a solution, which best corresponds to the needs of your business. Want to increase packaging efficiency? Contact us.