Raymond mill

- Type of equipment: Crushing equipment

- Applicable materials: Mining mining (For example, Calcite, limestone, Talka, Barita, Dolomite, Field Spattle, plaster and t. e in.), building materials, chemicals

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from manufacturers: Yes

Raymond mill - widely used grinding equipment. It is mainly used to grind various ores and other materials into powder. It has advantages of a wide range of subtleties of processing, stable work, convenient maintenance, environmental protection and energy conservation.

What raw materials can be grind for you Raymondovskaya mill?

The mill is a regular industrial grinding equipment. Many types of non -combustible and non -explosive materials can crush for you. General ingredients include:

Such as limestone, calcle, marble, talc, Gypsum, barite, phosphorite, clay and t. e. They are widely used in construction, chemical industry and mining industry.

Including grinding chemical raw materials, For example, Barium and carbonate sulfate.

Such as graphite, diatomite, Kaolin, etc.. e. It is also widely used in ceramics and other areas of application.

Agricultural products, Such as corn, wheat and t. e in., can be processed in powder at Raymond Mill for use in the food industry.

Used to crush coal, to make it more effective in the process of combustion.

Raymond Mill can be used for pre -processing and cleaning iron ore, Manganese ore, copper ore, chrome ore and other metal ores.

In general, it is suitable for processing various non -combustible and explosive minerals with firmness on the Moos scale below 9,3 And moisture below 6%. The size of the finished product on this machine is 60–325 bags (0,125–0.044 mm), And some materials can reach 1000 oven (0,013 mm). To achieve an ultra -thin grinding effect for you.

Like a Raymond mill crushes and grinds these materials for you?

Next, I briefly introduce you to the Mill Raimonda principle of work.

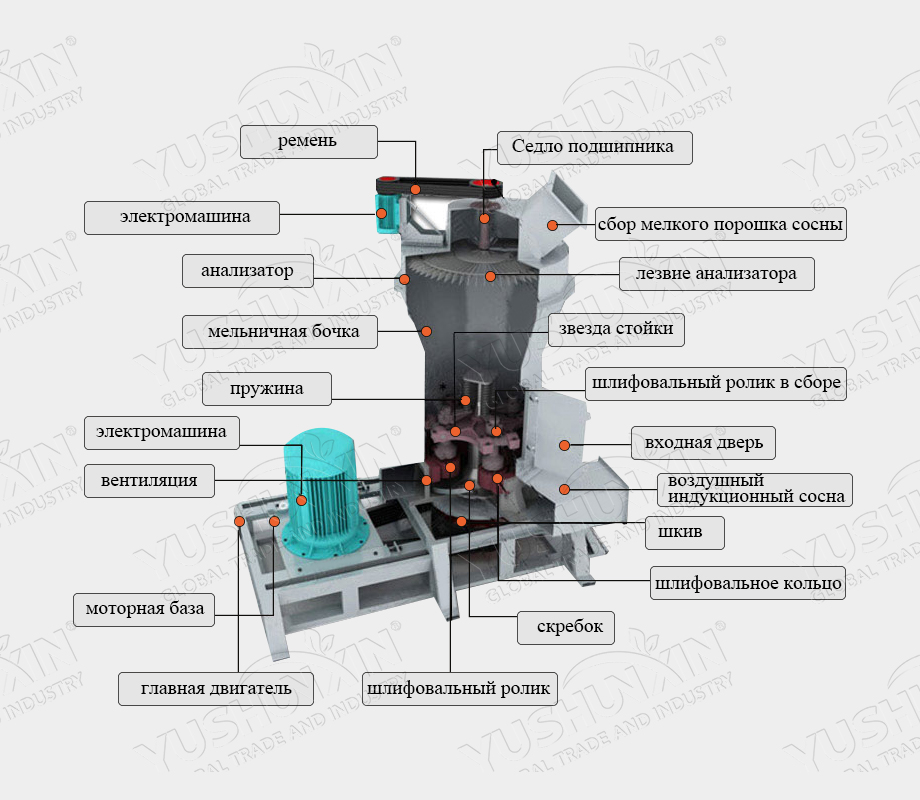

Materials, which must be chopped, loaded into the mill through a boot bunker, side of the machine. Grinding roller Inside the machine is tightly pressed to the grinding ring under the action of a high -pressure spring. Drive in motion oscillator The grinding roller rotates around the central axis and at the same time rotates around the grinding ring.

The material you add under the influence of gravity and centrifugal force will be thrown to the grinding ring, forming a layer of layer of material under pressure. The material is crushed by a grinding roll, and then chopped into powder. Crushed material is fed into analyst Using a fan. The powder is sorted in the analytical machine. Rough powder, not complies with the requirements for, will be returned to the mill for repeated grinding. Until it meets your requirements.

What are the advantages of the Raymond mill for your grinding process and for your production in general?

It can grind the powder to a high degree of grinding, And you can freely adjust subtlety. Raymond Mill drive device consists of a sealed gearbox and pulley. High grinding efficiency and high processing performance. The thinness of the grinding varies from 80 to 325 oven, and the degree of sifting can reach more 99%.

It has a long service life. Important components, such as grinding rolls and grinding rings, are made for you using high -quality casting, imported from Germany. This significantly increases the wear resistance and durability of equipment, which allows you to reduce the cost of maintenance and extend the service life of the equipment.

Simplicity of installation and operation. For crushing Raymond mills – We have developed a vertical design design for you. This can reduce the area, occupied by equipment. At the same time, centralized control of the electric system is used to increase the degree of automation. Allows you to control operations in real time. Make your production safer and more reliable, saving time and effort.

Compared to the traditional Raymond Greener, What optimization are there in a new generation Raymond Mill, To facilitate you to use it?

Raymond's traditional Mill is mainly used to grind various ores. If the performance is low or operation is wrong, This can easily cause dust pollution and affect the pollution index of adjacent territories. Therefore, the problem of equipment pollution attracted great attention to users.

Currently, As part of the propaganda of energy conservation and environmental protection, The decrease in dust pollution was the goal, which are haunted by manufacturers. Shunxin conducted extensive experimental research and introduced domestic and foreign professional technologies for constant optimization and improvement. Recently we released a new generation of the ecologically clean mill of Raymond. The machine uses the design of the overlapping sealed chamber chamber. The crushing cavity is deep, The tightness is good, Dust does not fly out. He effectively solves the problem of dust pollution for you and meets the requirements of environmentally friendly and environmentally friendly production.

What models of Raymond mills are currently available at our factory for your choice?

| Type | 6R4525 | 5R4119 | 4R3216 | 3R90

4R90 |

3R85

4R85 |

3R75 | 3R65 | 3R60 |

|---|---|---|---|---|---|---|---|---|

| The size of the feed particles (mm) | ≤30 | ≤25 | ≤25 | ≤25 | ≤20 | ≤20 | ≤15 | ≤15 |

| The size of the finished product (mm) | 0.125-

0.044 |

0.125-

0.044 |

0.125-

0.044 |

0.125-

0.044 |

0.125-

0.044 |

0.125-

0.044 |

0.125-

0.044 |

0.125-

0.044 |

| Production shifts of different large size (T) | 16-120 | 8-60 | 4-45 | 3-35 | 2-28 | 1.5-20 | 1-18 | 0.5-8 |

| The speed of the central shaft (rpm) | 82 | 105 | 130 | 160 | 160 | 160 | 180 | 280 |

| The diameter of the grinding ring (mm) | 1770 | 1400 | 1073 | 973 | 885 | 865 | 725 | 495 |

| The diameter of the grinder (mm) | 450 | 410 | 320 | 300 | 270 | 260 | 210 | 140 |

| The height of the grinding roller (mm) | 250 | 190 | 160 | 160 | 150 | 150 | 150 | 100 |

| The main motor | y315m-

4-132 |

y280s-

4-75 |

y225s-

4-37 |

y225m-

8-30 |

y225m-

8-22 |

y225s-

8-18.5 |

y200L-

8-15 |

y160m-

6-7.5 |

| Fan engine | y315m-

4-132 |

y250m-

4-75 |

y250m-

4-75 |

y180m-

4-22 |

y160l-

4-15 |

y160l-

4-15 |

y160m-

4-11 |

y132s-

2-5.5 |

| The analyzer engine | y160m-

4-11 |

yc200-

4B-7.5 |

yc120-

4a-5.5 |

y112m-

6-2.2 |

y112m-

6-2.2 |

y112m-

6-202 |

y112m-

6-2.2 |

y90l- 6-1.1 |

The full set of Raymond mill is used on phosphorus fertilizer production lines.

You can choose a suitable model and configuration of Raymond mill to perform grinding surgery, based on such factors, like hardness, humidity, Expected particle size after grinding the crushed materials, as well as performance requirements. Before choosing a Raymond mill, It is better to carefully test the material and . And you need to actively communicate with equipment suppliers, To make sure, that the selected equipment meets specific production requirements.

If you want to buy a Raymond mill, How much does it cost?

Our prices for the Raymond Mill vary from tens of thousands to hundreds of thousands. Different equipment models have different output power and engine power, as well as the subtlety of the finished materials they produce will also be different. Therefore, the prices for equipment also differ.

If you want to know, How much does a Raymond mill cost? You can use online consultation or contact us by contact information, indicated below. We have professional engineers, who will answer your questions in real time. And we can provide you with the design plans of the production line for grinding. Contact us now!

In addition to the Raymond mill, we also have crushing equipment, such as Solom crusher, War crusher And Wood crusher. If you are interested, Please, Contact us for photos and videos!

Frequently asked questions about Raymond Mill.

Crushing the Mill Raymond can be used in various fields. It can be used in various production processes, Especially there, where the materials must be chopped into powder. Since it allows you to regulate the subtlety of grinding, He can satisfy the needs of various areas. But whether the Mill Raimond is required in your production, depends on your specific production needs. Including such factors, as characteristics of your materials, Your requirements for processing, Your goals in the quality of products and costs. Below are the most common production fields of the Raymond mill for reference:

After that, how the material is crushed in Raymond crusher, The fan pumps the air flow into the main case, Thus blowing the powder up. The powder is sorted analyzer, located above the grinding camera. Too rude materials will fall back into the grinding chamber Raymond crusher for repeated grinding. The powder of acceptable size will fall into the cyclone collector along with the wind stream. After the collection, it is unloaded from the exhaust hole for the powder and is a finished product.

The air flow returns to the fan through the return duct at the upper end of the large cyclone manifold. The whole air path circulates and proceeds under negative pressure. The increased volume of air from the circuit of the circulating air is thrown out of the exhaust pipe between the fan and the main block into a small cyclone collector for cleaning.