A set of high -quality line for the production of mixed fertilizers is the basis for achieving efficient production and stable volume of products. Mixed fertilizer production line SHUNXIN fully developed, Starting with equipment configuration, planning of production capacities and ending with factory adaptation.

Be it a new enterprise, aimed at the development of the fertilizer market, or an experienced industry player, striving to modernize production. Shunxin mixed fertilizers production can accurately satisfy your needs and help you stand out in a rigid competition in the market. If you want to know more about the product, Contact us. Professional team will provide you with individual careful service!

If you plan to produce mixed fertilizers, What basic equipment do you need to purchase?

Intellectual dosing system.

The key to the quality of mixed fertilizers is the accuracy of the composition of the ingredients. Our automatic dosing warehouse is equipped with high -precision electronic dosing weights and automated control systems. It can accurately measure various basic fertilizers. The error range is strictly controlled within ± 0.5%. Our dynamic automatic dosing bunker can be preliminarily tuned to the use of various recipes programs. This allows you to quickly change the plans of the ingredients depending on production needs.

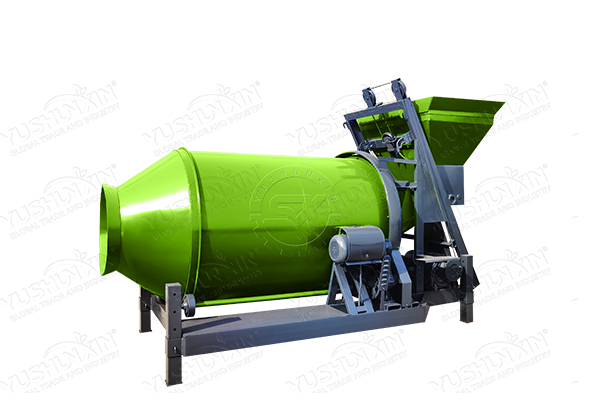

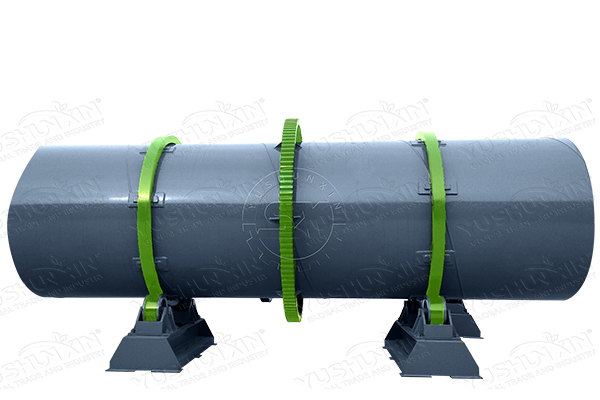

Effective mixing equipment.

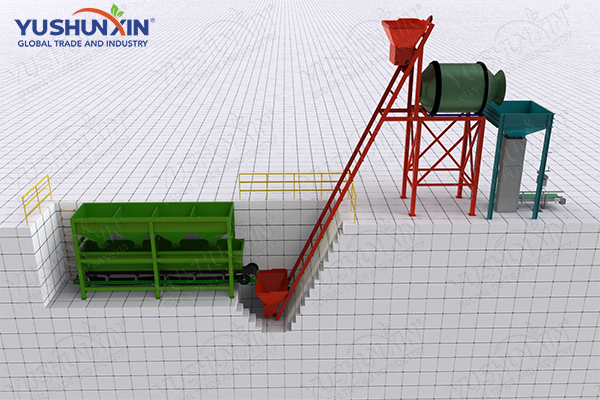

The mixing process is the key to ensuring the quality of mixed fertilizers. We have two main types of equipment: BB fertilizer mixer and drum mixer, which will satisfy your various production needs.

Fertilizer mixer BB: BB fertilizer mixer is also called a double -sized illiterate mixer. The unique internal biaxial structure of the blades is the basis for effective mixing. During operation, two stirring shafts rotate in opposite directions. The blades are driven in this way, so that the material creates strong convection, shift and diffusion movements in three -dimensional space.

A drum mixer: The drum mixer mixes the materials by means of a rotating drum. Inside the drum is a special design of the lifting plate. When the drum rotates, the lifting plate continuously lifts and lowers the materials. At the same time, the materials roll and slide in the drum, Providing multidirectional mixing.

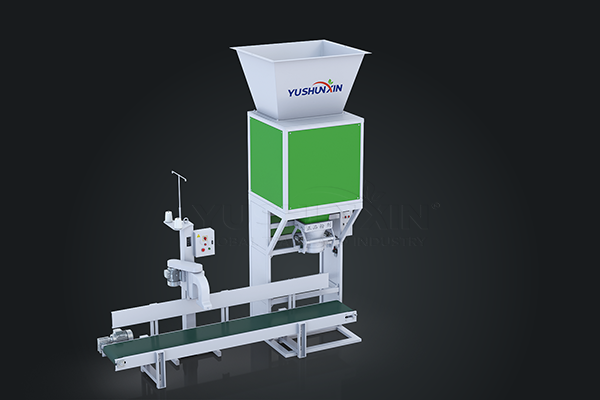

Fully automated packaging equipment.

Packaging process allows you to automate the whole process from dosing, Filling, Sealing before marking. No matter, Do you need packaging in 25-kilogram small bags, 50-kilogram large bags or ton bags, it can be easily satisfied. High -precision weighing sensor guarantees, that the weight error of each bag does not exceed ± 0.2 kg. At the same time, the packaging system is easily related to the production line information management system. He can automatically register a product of the product, Date of production, Formula and other information. It is convenient for you to carry out the traceability of products and quality control.

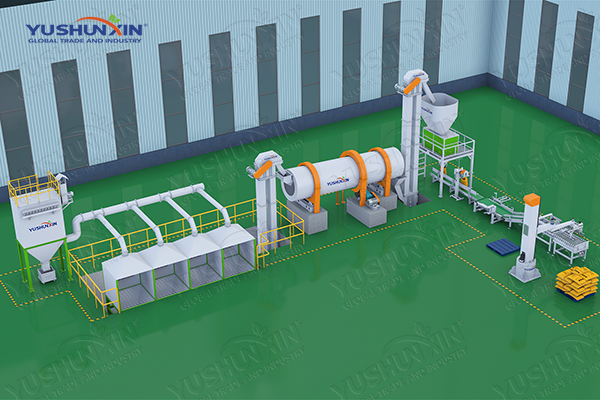

Two line of production of mixed fertilizers with various performance. Satisfy your diverse needs!

A small line for the production of mixed fertilizers with a capacity of 0–20 t/h/h.

A small production line with a capacity of 0–20 t/h uses as the main mixing Equipment Fertilizer mixer BB. All equipment of the production line has a compact design and simplicity of operation. You can quickly start work without the need to have technical knowledge. And the flexible mode of serial production allows you to quickly switch between different recipes. Satisfy the needs of small and diversified markets. The total energy consumption is low, What makes it an economically effective choice for small production enterprises.

Large production line with performance 20-40 subject.

Large production lines with performance 20-40 T/h intended for large manufacturing enterprises. As the main equipment in the mixing process, a rotating drum mixer is used. An advanced technology of continuous production is used on the production line. The whole process, From the transportation of raw materials, dosing, mixing until packaging, It is controlled automatically. Significantly reduce manual intervention, increase production efficiency and product quality stability.

Configuration of the equipment for the production of mixed fertilizers 1-20 subject.

| The output characteristics | 1-2 subject | 3-5 subject | 5-10 subject | 10-20 subject |

|---|---|---|---|---|

| Automatic dosing machine | ZP1200 | ZP1500 | ZP2000 | ZP2300 |

| Fertilizer mixing equipment | GJB-1200 | Gjb-1500 | GJB-1800 | GJB-2000 |

| Automatic dosing and packaging machine | KH-ZL-50 | KH-ZL-50 | KH-ZL-50 | KH-ZL-50 |

| The strip conveyor | SX-500 | SX-500 | SX-500 | SX-500 |

How much a large factory do you need, to invest in a mixed fertilizer production plant?

The area of the plant, necessary for investment in a mixed fertilizer production plant, closely related to the scale of the production line capacity. If you plan to invest in our small line of mixed fertilizer production, then you will need an area of about 200-500 square meters. Recommended, so that the height of the factory building is at least 6 meters. All equipment has a compact layout, And the storage area of raw materials, production zone and storage area of finished products are relatively independent. For companies with limited space, small production lines can flexibly adjust their layout, To maximize the space.

Our large -scale line for the production of mixed fertilizers with performance 15-40 t/h occupies an area of about 800-1500 square meters. The height of the building of the plant should reach 8-10 meters to accommodate large silos for storage, conveyor equipment and t. e. The building of the plant should be reasonably divided into the reception zone of raw materials, preliminary processing zone, production and processing zone, Packing area of finished products and storage area. Each zone is connected by automated conveyor equipment to ensure uninterrupted flow of materials. At the same time, equipment service channels and space for modernization should be reserved to meet the future needs of the company's development.

What fertilizer formulas are suitable for you developed for you for the production of mixed fertilizers?

- Universal formula: Universal formula, suitable for field crops, such as wheat, Rice and corn. For example, Classical n – P₂o₅ – K₂o = 15 – 15 – 15 or 16 – 16 – 16.

- Special formula for economically profitable cultures: Special formula, based on the characteristics of growth and needs in fertilizers of economically profitable cultures, such as vegetables and fruit trees. For example, The vegetable growing is usually used formula n – P₂o₅ – K₂o = 18 – 8 – 16.

- Formula for soil improvement: Formula for soil improvement to solve soil problems in various regions. Improve soil structure and increase its ability to retain water and fertilizers. Achieve a win -win situation for harvesting and improving the soil.

Why is shunxin mixed mixed fertilizers cost your investment?

High -quality equipment materials: Key equipment is made of stainless steel and special wear-resistant and corrosion-resistant materials. For example, Bunker of dosing weights, Inner lining of the mixer, transport pipeline and t. e. Effectively extend the service life of equipment and reduce the cost of maintenance and replacement. At the same time, chemical reactions between fertilizers and equipment are avoided, to ensure product quality.

Deep technical accumulation: Shunxin has been actively working in the field of equipment for the production of fertilizers for many years, has a professional team of R&D and owns basic technologies. From the design of equipment, Production before installation and commissioning of strict standards are observed. We guarantee, that each line of production of mixed fertilizers has excellent performance and stable quality.

Ideal after -sales service: Provision of professional installation and debugging services. The main personnel provides operators with assistance on the spot in the development of methods of operation and maintenance of equipment. Create a round -the -clock hot service line, In order to quickly respond to messages about equipment failures and, if necessary, provide remote recommendations or repair at home.

What are the payment methods for the production line of mixed fertilizers Shunxin?

To satisfy various needs of customers, our company supports several ways to pay. Flexible payments: T/T L/C D/A D/P и т. e. It will be convenient for you to choose in accordance with your own habits and the real situation, what will make transactions more convenient.

If you are interested in investing in the industry production of fertilizers, Contact us to discuss decisions. We have an extensive library library for the production of fertilizers, covering various processes and suitable for different scale. Whether it is a small -scale specialized production line or a large -scale intensive production system, We can choose the perfect solution for you. From advanced pre -processing of raw materials to intellectual packaging of finished products. We supply high -quality equipment, necessary for the entire process, to ensure the effective work of each production link. We also offer you a sincere gift - free professional drawings of the production line layout. Take the opportunity and contact us right now!