Farmers love liquid water -soluble fertilizers, because they are easily absorbed and easily used. For that, To help you respond quickly to market demand, We specially launched liquid water -soluble fertilizer. Our line for the production of liquid water -soluble fertilizers uses the most advanced automation technologies. This guarantees, that you can accurately control the ratio of various raw materials in the production process. This provides high quality and constancy of the final product.

The highly effective design of the production line not only increases the efficiency of production, but also significantly reduces energy consumption. Many customers, ordering At our factory lines for the production of liquid water -soluble fertilizers and put them into operation, They expressed satisfaction. Our line for the production of liquid fertilizers will help you achieve sustainable production and maintain a leading position in hard market competition.

What production equipment includes one of our standard production lines for the production of liquid water -soluble fertilizer?

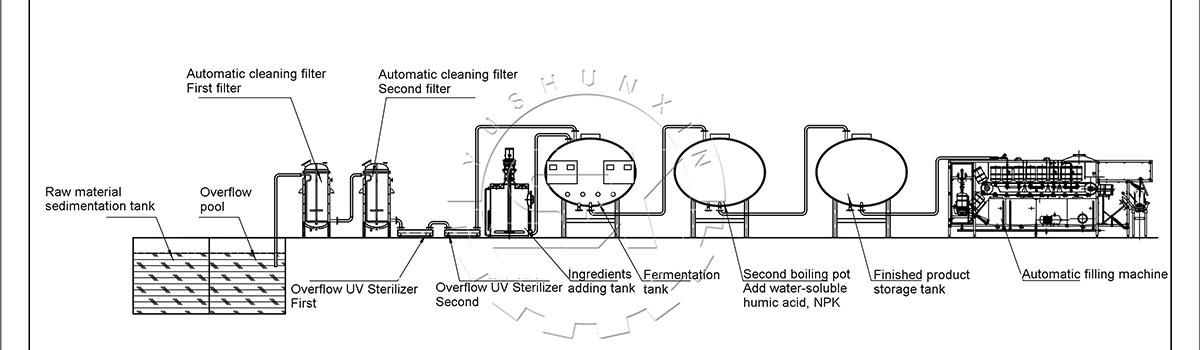

Our Standard line for the production of liquid water -soluble fertilizers Equipped for you near modern equipment. Guarantee of the efficiency and quality of products of your entire production process. At the beginning of the production line, it is necessary to build a sump of raw materials and an overflow reservoir. They are responsible for processing raw water. It removes heavy impurities by deposits and regulates the flow of water, ensuring the continuity of water supply.

To make the water quality meet the requirements, Our production line also includes two sets of fully automatic self -cleaning filters. They are responsible for primary and secondary filtration, respectively, removing impurities from larger particles. This provides a source of pure water for subsequent disinfection and preparation of fertilizers. Besides, Two overflowing UV sterizers are responsible for the primary and secondary disinfection. Use ultraviolet rays to destroy bacteria and viruses in water and ensure the safety of water quality.

After strict filtration and sterilization, nutrients, necessary for fertilizer, added accurately and in proportion to the dosing tank. and perform preliminary stirring. Then reaction and farment tanks are used for further reaction and fermentation of these solutions in order to increase the efficiency of fertilizers. If you want to add additional ingredients to complete the final mixture of fertilizers. You can use secondary equipment for chelating. For example, water -soluble humic acids and nitrogen, phosphorus and potassium (NPK). The finished fertilizer is stored in tanks for storing finished products until then, until it is ready to fill out.

At the final stage of the production process, our fully automatic spilling machines carefully pour the finished liquid water -soluble fertilizer into various packaging containers. And conduct subsequent processing, such as sealing and marking. We have developed this production line to achieve effective automation of production. And make sure, that the liquid water -soluble fertilizer produced for you has high quality and a balanced composition. Satisfaction of various market needs. This is just a production line of standard configuration. Specific equipment, which you will use, Depends on your specific situation.

What do you need to pay attention to, to ensure the stable quality of liquid water -soluble fertilizers, produced on the production line?

Ensuring the constancy of the quality of liquid water -soluble fertilizers, produced on the production line, is the key to the success of the product. Firstly, The quality of your raw materials should remain constant. It means, what ingredients, corresponding to standards, must be received from reliable suppliers. And make sure, that they are not polluted during storage. In the production process, the use of accurate formulas and automated dosing systems provides accurate proportions of the ingredients.

Besides, Mixing processes and dissolution must be carried out in strictly controlled conditions. Such as temperature, Mixing pressure and speed, to ensure the homogeneity of the solution. You must regularly calibrate and maintain production equipment, to avoid deviations, caused by wear or failure of equipment. You also need constant quality control. Having taken these measures, You can guarantee, that each batch of liquid water -soluble fertilizer will be equally high quality.

What are the advantages of the line for the production of liquid water -soluble fertilizers, which we provide to you?

- 1

Automated control: Our intellectual control system allows you to precisely dose raw materials. To ensure stable product quality for you.

- 2

Modular design: The line for the production of liquid water -soluble fertilizers has a modular structure. It will be convenient for you to expand and modernize later, to adapt to various needs of production power.

- 3

Energy conservation and high efficiency: The entire line works with low energy consumption. Effectively reduce production costs and increase your competitiveness.

- 4

Safety and environmental protection: In the production process, very little waste is formed, which meets the requirements for environmental protection.

- 5

After -sales service: We provide you with a full range of technical support and after -sales service, to ensure the uninterrupted operation of your production.

What liquid water -soluble fertilizers can produce a line for the production of liquid water -soluble fertilizers, which we provide to you?

Many popular species are presented on the market for liquid water -soluble fertilizers. Including Comprehensive nitrogen fertilizers, phosphorus and potassium (NPK), liquid fertilizers of trace elements, liquid fertilizers from seaweed and t. e. These products are popular among farmers because of their properties of immediate use and light absorption by plants. And our production lines can produce the aforementioned types of chassis products. Satisfy your needs in various markets.

Amino acid liquid fertilizer is one of the most popular liquid fertilizers in the market. What is his raw material?

In progress production of amino acid liquid fertilizers The cycle of enzymatic hydrolysis is usually 3-5 days. It depends on the enzymatic method, Anaerobic fermentation takes 2-3 the day. Aerobic fermentation occupies 4-5 days. During this cycle, microorganisms break down the proteins of raw materials and turn them into amino acids and other nutrients. It should be noted, that the choice of various raw materials and control of the fermentation process will affect the quality and effect of the final amino acid liquid fertilizer.

What methods can help you, if liquid fertilizer after enzymatic hydrolysis has a foam or not thick enough?

If liquid fertilizer after enzymatic hydrolysis has a foam or not thick enough, Two ways can help you. Firstly, You can add the corresponding number of natural sweeteners, such as honey, maltose, Brown sugar and emulsifiers, to increase fluid viscosity. These materials have a relatively low cost and are an economical option for increasing viscosity. You can also add calcium chelate Eda Or a special emulsifier, But it is more expensive.

Be it traditional solid fertilizer, solid liquid water -soluble fertilizer or new liquid water -soluble fertilizer. We all strive to provide customers with flexible and effective production solutions, providing the highest quality. We count, whatever the market changes. Constant technological innovations and excellent customer service will be our key to that, To help you stay competitive. We are looking forward to working with you!