Solution: Quail litter like fertilizer

- Performance: 1-30 T/hour.

- Price: 390 000 rub. – 66 000 000 rub.

- Raw materials: Quail droppings, straw, straw, peat, Organic waste…

- Scope: Production of dung organic fertilizers.

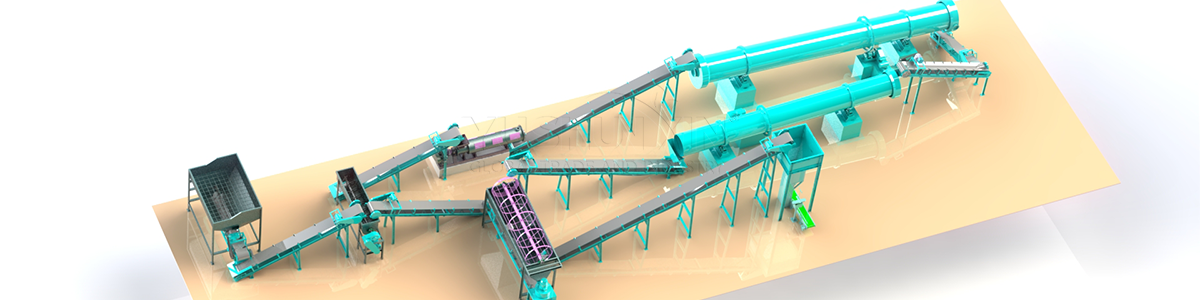

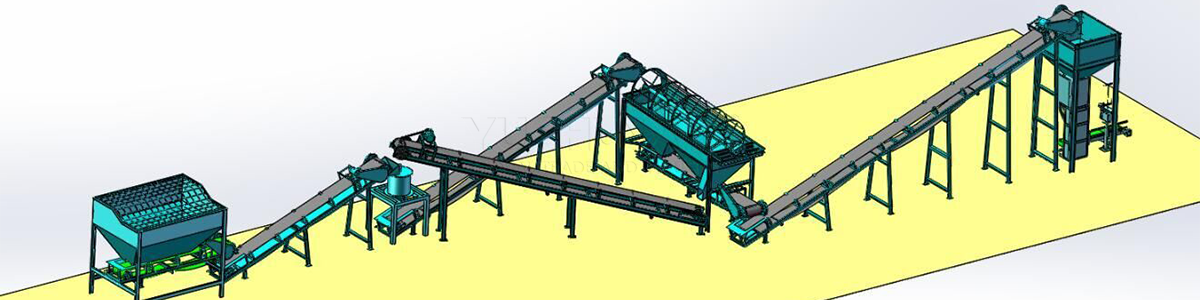

- Production line process: Pre -processing, fermentation, crushing, mixing, granulation, Drying, cooling, package…

The line for the production of organic fertilizers from quail droppings is a highly effective production system, which converts quail litter into high -quality organic fertilizer. Thanks to the integration of advanced equipment and technologies, the production line provides effective work at each stage - from raw materials to finished products. Quail litter as fertilizer of a solution is able to satisfy the needs as small, and large industries. Make sure, that you can produce high -quality organic fertilizers. We provide personalized setting services to meet the needs of various customers. To learn more or configure your production line, Contact us.

Production process of quail litter as fertilizer.

Thanks to the scientific approach and effective equipment, quail droppings can be completely disposed of. Thereby turning into high -quality organic fertilizer. We offer a full range of equipment and information. Ensure the effectiveness of production processes and product quality. If you need it, Contact us to purchase equipment. We are looking forward to providing you with high -quality equipment and services, which will help your business in the production of organic fertilizers.

The production process of processing quail litter into organic fertilizer includes the following main stages:

- Collection and primary processing: Fresh quail litter is collected and sifted to remove impurities.

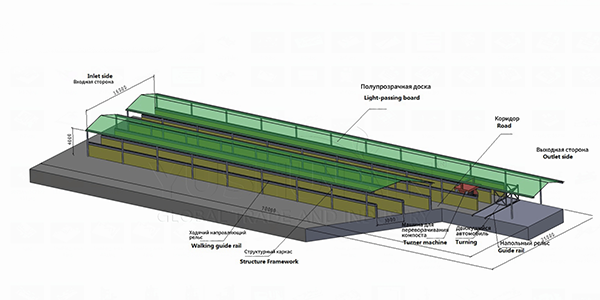

- Fermentation compost: In equipment for fermentation compost, manure and auxiliary materials are mixed in proportions. Enzymation for decomposition of organic substances.

- Crushing: Fermented materials Grinded using crushing equipment to obtain small and homogeneous particles.

- Granulation: Crushed material turns into granules using granulator.

- Drying and cooling: Granuls are dried in a dryer to control moisture content, and then cool.

- Packaging and storage: The finished organic fertilizer is packaged for the convenience of storage and transportation.

What are the properties of quail litter as fertilizer?

Quail litter - highly effective organic fertilizer. He is rich in macro elements, such as nitrogen, phosphorus, potassium, as well as microelements and organic substances, such as calcium, magnesium, Sera and t. e in., necessary for plant growth. High content of organic substances helps to improve the structure of the soil. For example, He can improve the retention of moisture in the soil and its aeration, improve soil fertility and increase microbial activity. Thus providing plants with continuous supply of nutrients.

The use of quail litter not only increases the yield and quality of the crop, but also has environmental advantages. In addition to direct use as a fertilizer, quail litter can also be processed and turned into products with high added value, such as complex fertilizers and liquid fertilizers. Therefore, quail litter as fertilizer is an investment, which is worth considering.

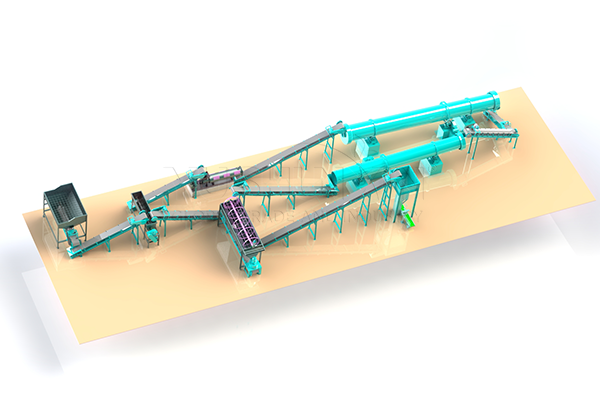

What key equipment do you need to prepare a small line for the production of quail litter?

In production, quail litter as fertilizer with key equipment is equipment for fermenting compost and crusher. One guarantees the quality of the finished fertilizer, and the other is the commodity of the finished fertilizer. Equipment for composting, such as compost enumber and fermentation vapors, contributes to the effective decomposition and stabilization of organic substances by creating a suitable environment (temperatures, moisture, ventilation, etc.. e in.). Thanks to sufficient fermentation, compost maturity and uniform distribution of nutrients are ensured, What is the key to high quality fertilizer.

After completion of fermentation The crusher grows the material On small particles, to ensure the consistency and uniformity of the material. This reduces the problem of low quality, caused by large or uneven particles, and guarantees the quality of finished products. If later you need the granulation process, The granulation effect can also be guaranteed. These two parts of the equipment play a vital role in the production of quail manure. Ensure the quality and efficiency of processing at each stage from raw materials to finished products. If you need to purchase this equipment, Please, Contact us for consultation.

How to control the humidity of the finished fertilizer from quail litter?

In the production of fertilizer from quail litter, the control of humidity of the finished fertilizer is a key step to ensure the quality of the product and stable storage. Moisture content in powder fertilizer should usually be controlled at the level below 20%. So that the fertilizer does not lump during storage. You can control the moisture content during the composting process, adjusting the aeration and frequency of turning the compost from quail litter at the composting stage. Give the compost to end with moisture content from 20 to 30 percent. Then reduce the moisture content to less 20% by drying naturally or using drying equipment.

The moisture content in granular fertilizers should be maintained at the level below 10 %, which helps to extend the shelf life and prevents the destruction and combination of granules. You can use our drying machine. The moisture content in granular fertilizer is reduced to less than 10% with hot air. When using it, you need to make sure, that the temperature and drying time are set correctly, To prevent overdrying the surface of particles or non -functioning of internal moisture.

How do you choose a suitable granulator in the production of organic fertilizer of quail manure?

First, What needs to be done, This is to choose the right granulator in accordance with the scale of your production. Different models of granulators have different production capabilities, So make sure, that the equipment you have chosen meets your production needs. Consider the material and assembly quality of the device, to ensure its strength and a long service life. The most important thing is to make sure, that the costs of buying and operating equipment are within your budget.

You can contact the equipment supplier, Before making a final decision. Obtaining demonstration versions of equipment and selective tests can be very useful. This will help you better understand the performance and suitability of your device. If you need an additional consultation or help in choosing a suitable granulator, Contact us. We will provide you with professional advice and support.

Using quail litter as fertilizer, you can not only effectively use waste, but also produce high -quality organic fertilizer. Our line for the production of organic fertilizers from quail litter is equipped with scientific processes and effective equipment. We will help you produce high -quality organic fertilizers. We not only supply a line for the production of quail litter, but we also offer solutions for many other fertilizers production lines. For example, The line for the production of organic fertilizers from chicken droppings, Complex organic fertilizer production line, Liquid organic fertilizer production line and t. e. To obtain additional information or personalization, contact our professional team.