Solution: Production of powdered fertilizers

- Performance: 1-30 T/hour.

- Price: 390 000 rub. – 66 000 000 rub.

- Raw materials: Feces, Organic waste…

- Areas of application: Organic fertilizer production enterprises, farms, countryside…

- Production line process: Fermentation, crushing, screening, Dosage, crushing, mixing, screening, package…

Organic fertilizers are divided into powder and granular. Since powdered organic fertilizers do not need granulation, Investments in line for the production of powdered organic fertilizers relatively small. It does not require a large number of equipment. For some chickens, sheep, pigs and other tribal factories are a very suitable investment project.

How to fight feces, produced every day, which has become a big problem for the tribal factory? He was heated all the time, Not only the smell is unpleasant, but small organisms like mosquitoes and flies can propagate. It's normal in winter, But in the summer it is sad. But on that, To fight these feces every day, It takes a lot of effort and time, What is unprofitable for you. The line for the production of powder fertilizers can help you very well solve this problem.

It turns manure into organic fertilizer by fermentation. The whole process can be divided into two parts: Fermentation and further processing. At the fermentation stage, they mainly use Microorganisms. Turn your annoying poop into organic substances using the fermentation process. The deep processing stage consists in turning these fermented semi -finished products into finished products by crushing, begging, packaging and other types of processing. You can use the final product yourself or sell it to others. Certainly, If you have enough money, You can also purchase equipment, necessary for the granulation process. Produce granular fertilizers and expand your fertilizer production line.

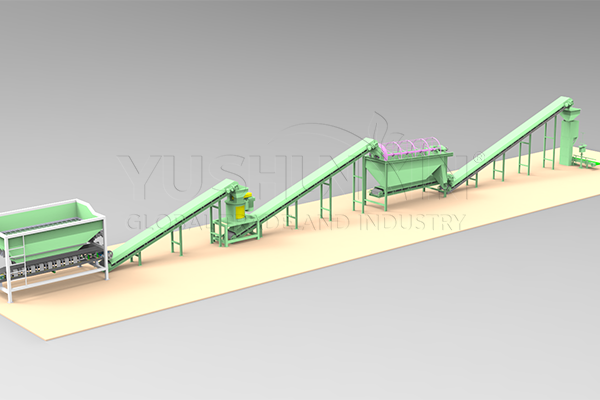

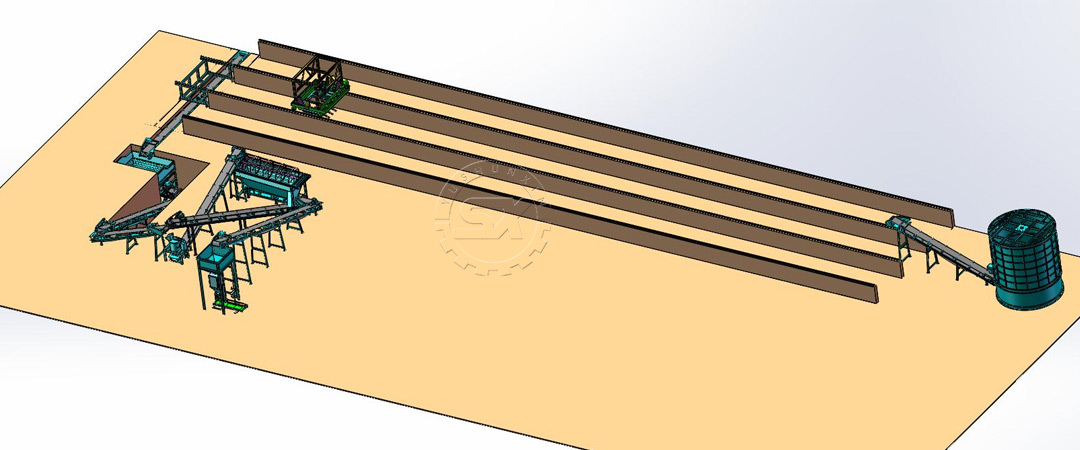

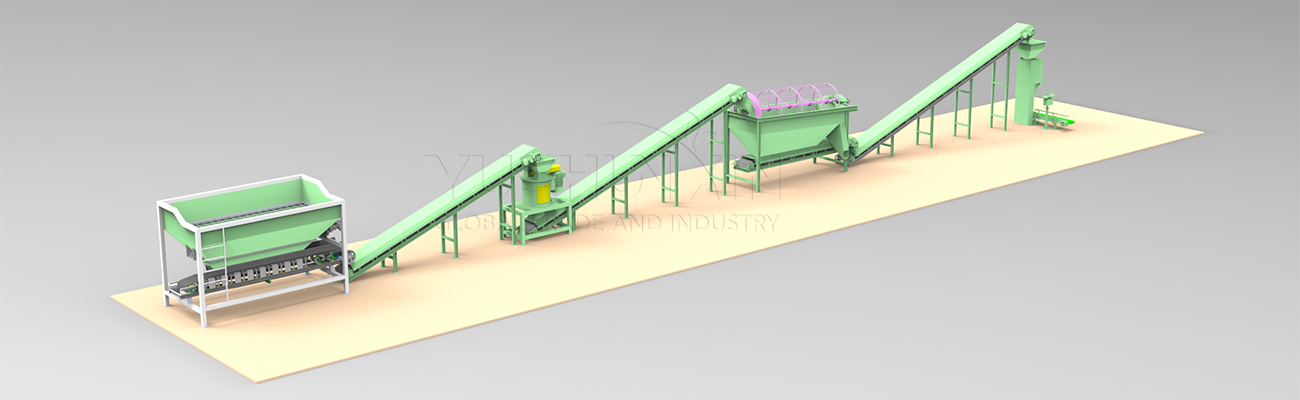

What equipment is included in the line for the production of fine powder organic fertilizers?

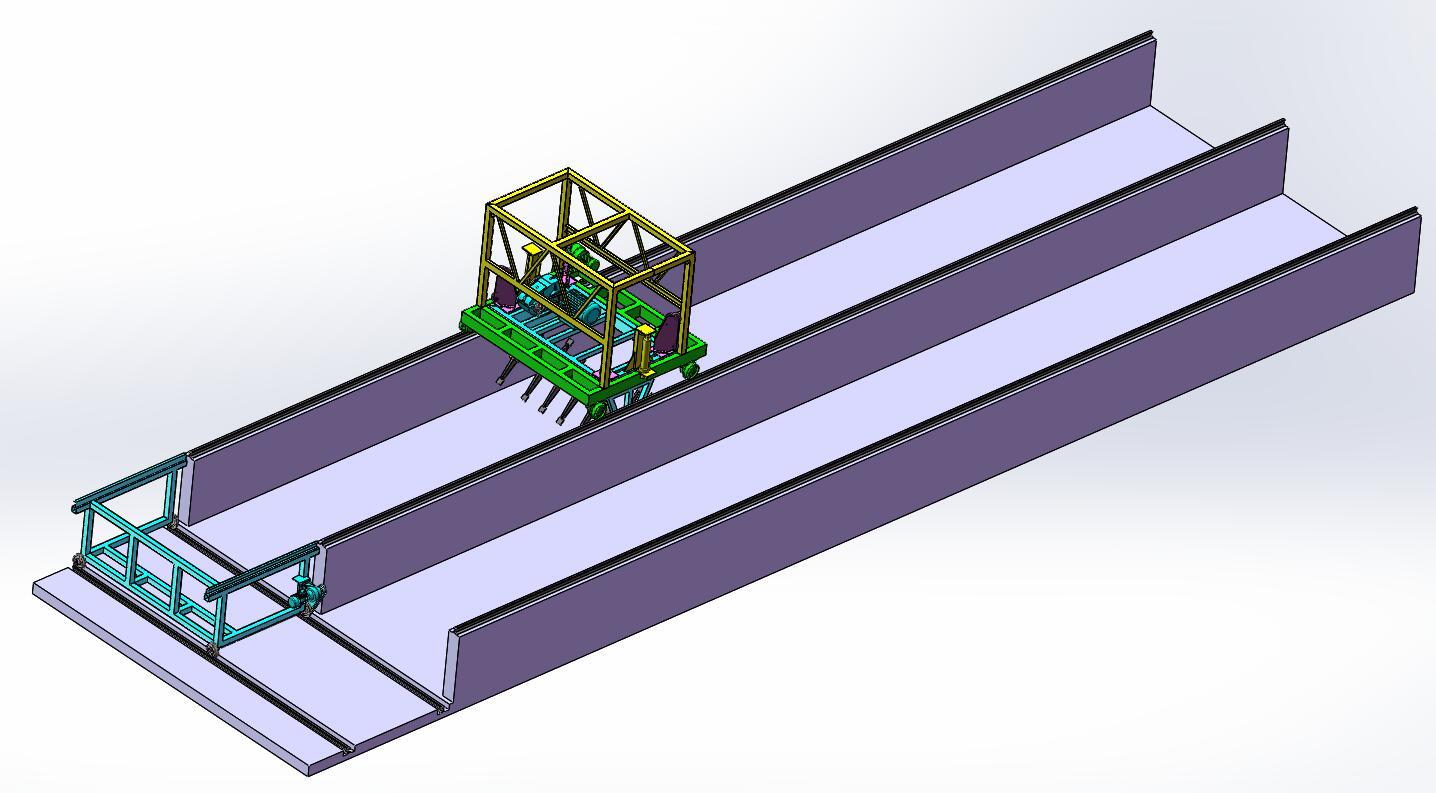

Groove type compost turner (You can also choose a self -propelled composter), Horizontal mixer, Grinder of half -fingered material, A drum carrier machine, Automatic packaging scales. This simple and small equipment for processing organic fertilizers is very suitable for processing manure by some farmers and small tribal factories.

What raw materials can you choose for the production of powder organic fertilizer?

The most important point is, that you must choose the right raw material for production in accordance with local conditions.

- Manure: Chicken, pork, measly, Sheep, horse, Rabbit, quail, Pigeon and other animal manure;

- Straw: Corn stems, Corn cobs, Rice straw, Wheat straw, Straw from beans, Sweet potato straw, rice straw and t. e in.;

- Sludge: household sludge, sugar factory filter, Paper sludge, etc.;

- Other categories: Carcasses of animals, household garbage, Bone flour, leather, etc.;

- Add raw materials: Plant growth regulators, Synergists, anti -dazzle, dyes, bleaches, adhesives, Medium and trace elements, Macro elements, Materials-carriers, etc.. e.

In the production process, the entire line for the production of powder fertilizers, What stage is the most important?

In the entire production process, the most important is the whole process of fermentation. It determines the quality of the fertilizer you produce.

The fermentation process includes the ratio of raw materials, enzymes (A lane pile), adding strains and turning stacks for fermentation.

Firstly, You need to mix manure with the right amount of straw powder. The amount of straw flour is determined by the humidity. Generally speaking, the moisture content in the fermented material is about 45%. That is, it can be kneaded with your hands in a lump, and water is visible between the fingers, but she doesn't drip, And she will disperse, As soon as you let go.

Then you need to add the prepared mixture to the blender and beat. Mixing should be enough to achieve uniform mixing without the formation of raw lumps.

The next step is to add a mixed mixture in the groove of enzymes for fermentation (Or in a stack. The length is not limited, width 2 m, The height is near 1 m. Stage evenly.) Add bacteria and turn over. Turn over once in 1-2 the day. Until the end of the fermentation.

How to determine, Whether your compost has matured for fermentation?

Generally speaking, On approximately the fourth or fifth day, the smell can mainly be eliminated. On about the seventh day you will find, that compost becomes loose and dry, White mycelium appears. On approximately the ninth day you can smell malt in compost. At this time, compost is not far from complete fermentation and maturity. You just need to wait a few more days.

Why can't you sell fermented and mature materials directly?

Thethen connected with that, that during a long process of composting, the material will be agglomerated. At this time, you need to process the transferred raw materials. Grind finely through Grinder of half -fingered material, to get powdered organic fertilizer.

To improve the appearance, We will also prepare for you Drummering car on the production line. The resulting powder organic fertilizer is re -sifted, to get a homogeneous and homogeneous powder fertilizer. These pure powdered organic fertilizers can be packaged and sold further.

What is the price of equipment for the production of powder fertilizers with annual performance 5000 tons and 10000 ton?

These devices have different configuration parameters and technical specifications, Therefore, they differ in price. It depends on your specific situation. In general, the price will vary from 400 000 to 1 300 000 rubles.

What are the main factors, which affect the price of the purchase of equipment for the production of powdered organic fertilizers?

Configuration of lines for the production of organic fertilizers with different raw materials is different, And the price is also different.

This is the main factor, determining its price. We have a saying, that "you get then, What do you pay for ", the better the quality of the equipment, used in the line for the production of powder organic fertilizers, The higher the price will be. That's why, When you buy equipment for organic fertilizers, Do not greedy cheap, Quality is fundamental. Only high -quality equipment can provide good operation of the line for the production of organic fertilizers.