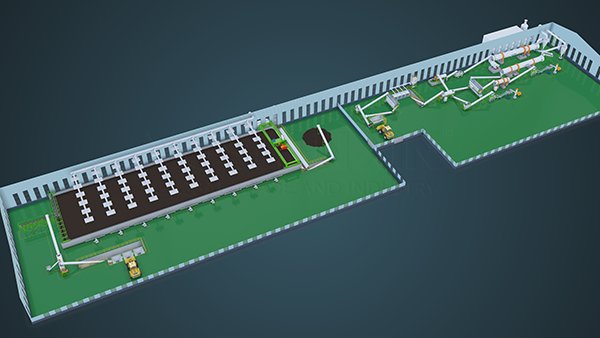

Solution: Production of organic fertilizer from lignite

- Performance: 1-30 T/hour.

- Price: 390 000 rub. – 66 000 000 rub.

- Raw materials: lignite, Elusted coal, cattle and poultry, Organic waste, nitrogen, phosphorus and potassium…

- Production line process: Crushing, fermentation, screening, Dosage, Grinding, mixing, granulation, screening, Coating, package…

Lynetic organic fertilizer is a new type of fertilizer. Due to the low cost of production and a small environmental environment, it attracts more and more attention from agricultural enterprises and farmers. We launched brown coal as a fertilizer of a production line. Designed, To help you turn brown coal resources into high -quality fertilizers. Achieve a win -win situation of economic and environmental benefits. Our line for the production of organic fertilizers from brown coal uses advanced technological processes and the exact design of the equipment. Ensure the efficiency and stability of each production link. From the processing of raw materials and fermentation to granular and packaging - our systems are carefully tested and optimized. To achieve the best production results and product quality.

If you want to take advantage of the transformation of "green" agriculture, Investing in the production of organic fertilizers from brown coal, Undoubtedly, It is a wise choice. Would you like to expand your existing business or find new investment opportunities. We have complex solutions and professional teams, who will provide you with support. Welcome, Contact us anytime, To learn more about the line for the production of organic fertilizers made of brown coal. Let's work together, to contribute to the development of sustainable agriculture and the achievement of greater value.

What is the production process of brown coal as a fertilizer of the production line, which we launched for you?

The whole process is controlled through an automated control system. Ensure the efficiency and stability of the production process while reducing the complexity of manual operations. If you need a line for the production of powder organic fertilizers from brown coal. Then all processes after the granulation process (Including granulation) They are unnecessary for you. If you want to produce granular brown -angle organic fertilizer, then subsequent granulation and other processes are needed. If you have more personalized needs, Please, Contact us. We will set up equipment and process in accordance with your situation.

How much do you need to spend, to buy brown coal as a fertilizer of a production line at our factory?

The line for the production of organic fertilizers from brown coal is divided into powder production line And granules production line. The price of the line of powder organic fertilizers is usually not too high. Equipment for a small line for the production of powder fertilizers can cost about 20 000 dollars. The line for the production of powder organic fertilizers made of brown coal of high performance can cost 50 000 US dollars.

The cost of the production of granular fertilizers is usually higher, than the production of powder fertilizers. A small line for the production of organic fertilizers in the form of granules from brown coal can cost about 50 000 US dollars. And large or highly automated production lines can cost Hundreds of thousands of dollars. To get prices for specific production lines, You can contact us by phone or email!

What equipment includes brown coal as a fertilizer of a production line, which we provide to you?

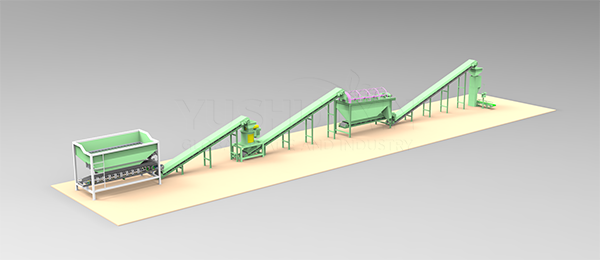

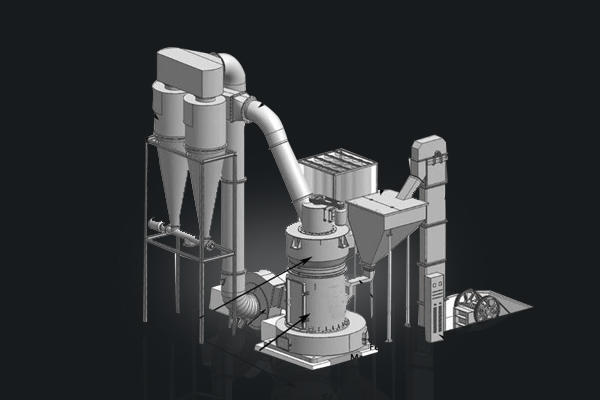

Used for grinding brown coal into small powder to improve its reactionary ability and uniformity of subsequent processing. This step increases the surface area, thereby increasing the effectiveness of its decomposition.

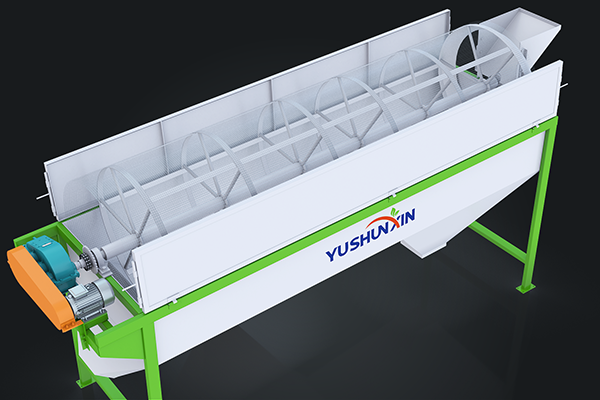

Used for Sorting of brown -round materials, which do not meet the requirements for the size of particles. Make sure, that material, for the next stage of processing, has the same particle size. Sifting machines are used at different stages to meet various sorting requirements.

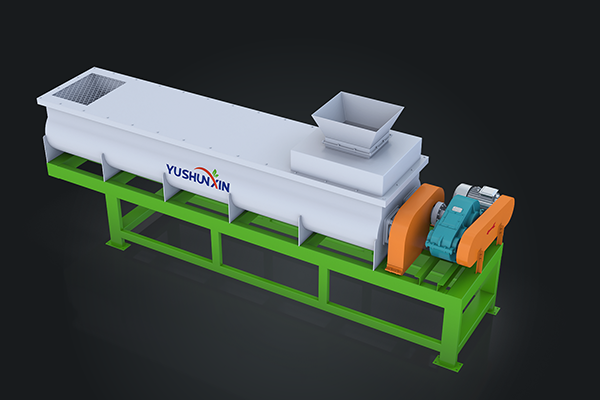

Here brown coal mixes with other organic substances (For example, manure and bird manure, vegetable residues and t. e in.). Increase the effectiveness and stability of organic fertilizers through microbial fermentation.

Further grinding of fermented and decomposed materials to the size, necessary for granulation. Provide the smooth course of the granulation process.

Crushed materials roll into granules. This is a key stage production of granular organic fertilizers, determining the shape and density of granules. The usually used equipment for granulation includes disk granulator, Drum granulator, Granulator of organic fertilizers and other granulation equipment.

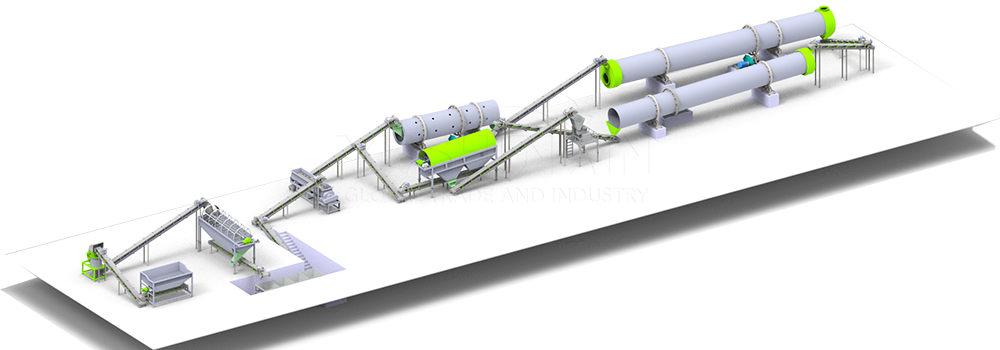

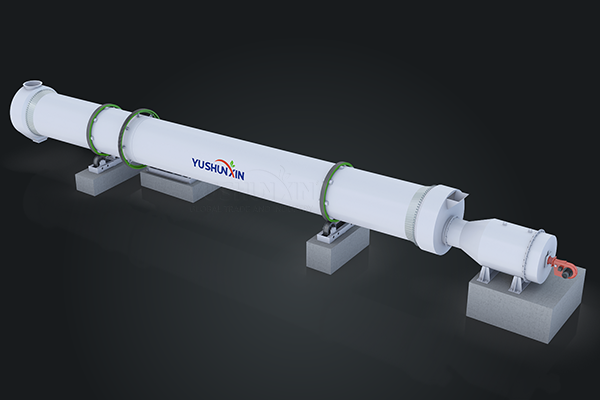

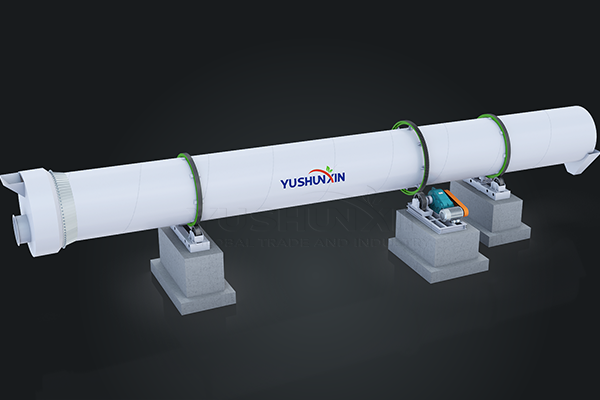

Dryer Used to dry particles of brown -angle organic fertilizer and reduce the content of moisture in them. Cooler Used to cool fresh particles of organic fertilizers and reduce their temperature. To facilitate subsequent packaging and storage.

Sift the chilled particles, to ensure their homogeneity. And separate large particles and small powder for re -processing.

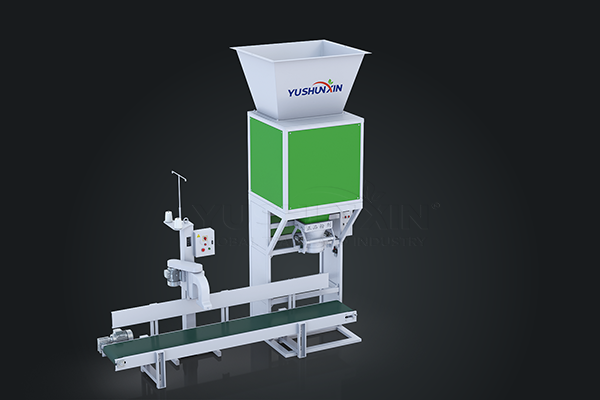

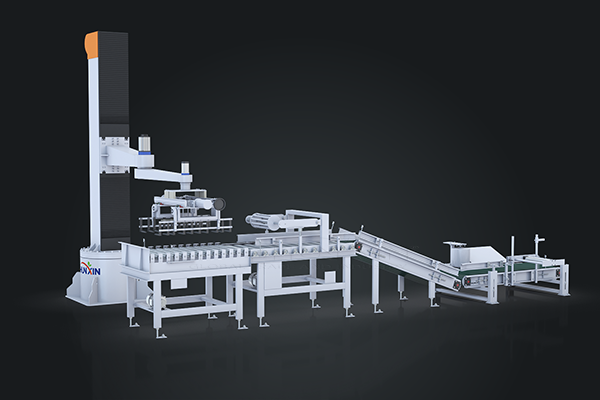

Packaging of the final product To facilitate transportation and sale. Make sure, that the characteristics of the product correspond to market demand.

These devices work together, forming a full production process, from processing raw materials to packaging finished products. Guaranteed to help you produce high -quality organic fertilizers from brown coal. Each device has its own unique functions and is indispensable in the production line.

Is your investment worth the production of organic fertilizers made of brown coal?

From the point of view of raw materials for production, brown coal is a common and cheap raw material. If you plan to produce a bulky organic fertilizer, Your raw materials costs will be minimal. As for market demand, since the market demand for organic fertilizers continues to grow, The popularity and demand for organic fertilizers made of brown coal are also growing. You can produce a variety of products to meet various market needs using organic fertilizers made of brown coal. Moreover, How manufacturer of equipment for the production of fertilizers with more than 20 years of experience, Our production technology is very mature. Significantly reduce your investment risk.

Why brown coal is better to use for fertilizer production, how to sell it as fuel?

In terms of use. Lignet is low -grade coal in the fuel sector and is less effective as direct fuel. And there are significant advantages, When you process it for fertilizer production. Firstly, Brown coal is rich in organic substances, What makes it the perfect material for the production of fertilizers. Secondly, Brown coal contains many minerals and trace elements. These ingredients are very useful for plant growth. Provides the soil with additional nutrients.

In terms of economic benefit. The effectiveness of the combustion of Ligne is low, and its market value is low as fuel. Since it is strongly polluting fuel, Its use is subject to restrictions or additional taxes. But if you process it into fertilizers through our production line. Avoiding its shortcomings as ineffective fuel. This can create for you a higher economic value and market demand. Lay a strong foundation for the long -term development of your business.

Why is fermentation needed in the production process of brown -angled organic fertilizers?

Fermentation It is an important stage of production of brown coal as a fertilizer. Its main goal is to transform the organic matter of the brown -angle compost through the activity of microorganisms into a nutritional form, which is more easily absorbed by plants. Therefore, fermentation is necessary in the process of production in brown coal as a fertilizer. Below is the importance of fermentation for the production of organic fertilizers from brown coal:

If you are interested in the production of organic fertilizers from brown coal, What raw materials do you need to prepare?

Among the uses of brown coal in the production of organic fertilizers, brown coal is most important. This is the main raw material, giving organic substances and basic nutrients. But in addition to the most brown coal, it is necessary to prepare other related materials and substances, to increase the efficiency of its fertilizer and improve the structure of the soil. Contribute to compost enzyme. Included:

In the production process, you need to follow, so that these ingredients are carefully mixed. And conduct scientific enzymatic treatment for the production of high -quality organic fertilizers. Temperature control, moisture and ventilation conditions during fermentation is also the key to successful production. Here not only effectively used brown coal resources are used, but also environmentally friendly organic fertilizers are produced.

How thin should the raw materials be to obtain granules of organic fertilizer of brown coal with a diameter 4-6 mm?

If you want to ultimately get brown coal, granular organic fertilizer with a diameter 4-6 mm, then it is necessary to grind raw materials to a smaller level. Provide the passage of the boiling powder through a sieve 60-80 oven (it means, that the size of the particles of crushed raw materials should be less 0,18-0,25 mm). Such subtlety provides good plasticity and coherence of raw materials in the granulation process. Able to form homogeneous particles and ensure the quality and stability of particles.

If you want, so that brown -angle organic fertilizers are more beautiful, which device can you buy?

If you want to make particles of organic fertilizers of brown coal more beautiful and round, You can consider the possibility of purchasing a machine for rounding organic fertilizers. A machine for rounding organic fertilizers, Also known as a machine for grabbing balls. This is a device, specially used to improve the form of particles, to make them more smooth and homogeneous. It can polish and form the particles of irregular shape to improve the appearance. Helps to increase the competitiveness of your products in the market.

If you want to produce 30 tons of boiling organic fertilizer per day, Which of our granulators can you choose?

If daily working hours of your plant are 10-15 hours. We recommend that you choose our disk granulator SXYZ-3000. The production capacity of this granulator model is 2-4 subject, which is very suitable for your needs. During working hours, he can bring you performance 20-60 T/h every day. He can fully satisfy your daily production need for 30 t/h of organic fertilizers made of brown coal. In order to optimize the production process, we recommend that you carry out reasonable planning and debugging the production line before the equipment commissioned. Ensure efficient operation of brown coal granulation equipment.

As a manufacturer, specializing in equipment for the production of fertilizers. We can provide not only lines for the production of organic fertilizers from brown coal. We also have Phosphorus fertilizer production line, The line for the production of organic fertilizers from chicken droppings, NPK production line and other products for your choice. If you have investment plans for the fertilizer production line, Contact us! We will select for you the best fertilizer production plan, Based on your specific situation!