NPK production 10-20 t/h - a profitable investment, which provides your company with a stable output, quick return of capital and expansion of the sales market. Integration of a modern production line allows you to improve the quality of granular fertilizers, minimize raw material losses and automate key process steps. At every stage - from the preparation of raw materials to the packaging of granules - you receive quality control, what is important for competitive work in the agricultural sector. Due to the modular structure, the complex adapts to your tasks and allows you to flexibly scale capacity. If you are planning to increase your production capacity or expand your NPK fertilizer production business, Please, Contact us to get professional consultation. We will help you choose the optimal solution and calculate the project estimate.

What types of equipment for NPK production 10-20 t/h we can offer you?

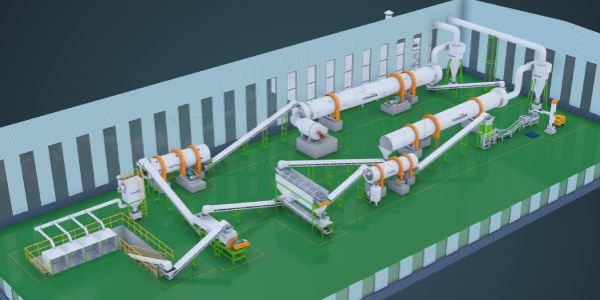

The modern NPK fertilizer production line includes several types of machines, each of which is responsible for its own stage of the production process. The standard kit includes a crushing machine (such as Urea crusher or Cell Crusher), mixing machine (Horizontal mixer or Vertical mixer), as well as the main granulator - e.g., drum granulator or disc granulator. For drying and cooling granules you get a rotary drying and cooling machine. All equipment is supplied as part of a single complex, which guarantees high automation and minimal maintenance costs.

The NPK fertilizer granulation process requires precision at every stage: preparation of raw materials, humidity control, uniform mixing of ingredients and formation of granules. For this purpose, various equipment models are available to you., adapted to the specifics of raw materials and scale of production. Consult our specialists, to pick up cars, suitable for your factory.

What is the price for NPK production line 10-20 t/h you can expect from us?

Price for NPK granulating equipment 10-20 t/h depends on production line configuration, selected machine models and additional automation options. You can get a basic set of equipment or an extended set with additional features - e.g., automatic feeding and packaging system. We provide a transparent pricing system, We take into account the individual wishes of clients and help optimize costs at the start of the project.

The price includes not only the main machines, but also components, such as dosing devices, sifting and packaging machines. Our specialists will calculate the estimate in detail, based on the needs of your company. To receive an individual commercial offer, you can contact consultants and ask all your questions about price and delivery conditions.

Which NPK fertilizer granulation technologies allow you to obtain a high-quality product??

High tech NPK fertilizer granulation process ensures the formation of granules of uniform size with optimal strength and solubility. Use of modern granulators, such as disc and drum machines, allows you to obtain granules of a homogeneous structure, which makes storing them easier, transportation and application to the soil. An automated humidity and temperature control system at each stage guarantees stable product quality.

You also get the opportunity to integrate additional options, For example, dust collection and automatic packaging systems. Thanks to this approach, the production line runs smoothly and guarantees you a granular product., compliant with international standards.

How can you benefit from automating your NPK production process? 10-20 subject?

Automation is a key factor for increasing production efficiency. NPK production line 10-20 t/h is equipped with modern control systems, which allow you to control all stages of the process chain. You reduce the human factor, improve the accuracy of component dosage, reduce the consumption of raw materials and minimize possible losses. Implementing automated solutions significantly reduces operating costs and allows you to quickly respond to fluctuations in demand. Besides, you get the opportunity to flexibly customize the production process parameters, which is especially important when working with different types of raw materials and producing fertilizers with different compositions.

What operational benefits do we provide you for smooth line operation??

Reliability and ease of maintenance of all line nodes are an important advantage of our equipment. We take into account the requirements for quick replacement of wear parts and minimal downtime. Each granulating machine, drying or mixing is designed taking into account the Russian specifics of operation. You get access to service and spare parts, allowing you to maintain high levels of productivity.

Thanks to the use of high-quality materials and modern design solutions, equipment service life is significantly increased. You also get the opportunity to integrate diagnostics and equipment condition monitoring for timely maintenance. Consultation on operational issues is always available to your specialists.

What are the possibilities for expanding and upgrading the NPK production line? 10-20 t/h we offer you?

The growth of the fertilizer market requires flexible solutions for scaling production. We design lines to accommodate future power increases - e.g., by installing additional granulators or mixing machines. You can easily implement new technological processes, adapt equipment to changing market requirements, as well as integrate modern digital solutions for remote monitoring.

Comprehensive modernization solutions are available to you: installation of new nodes, software update, implementation of energy efficiency systems. Specialists will help you choose the optimal configurations for your enterprise, will provide competent selection of equipment and full support at all stages of production expansion.

Today, the introduction of a modern NPK production line with productivity 10-20 t/h is a strategic solution for the successful development of your business in the agricultural industry. Each set of equipment comes tailored to your needs, as well as warranty and service support. Shunxin Fertilizer Production Equipment - this is quality, time-tested, competence in the selection of machines for granulating NPK fertilizers and an individual approach to each client. If you want to know more, get a cost estimate or order a line based on an individual project - contact us for a consultation. We will provide you with reliable support, optimal solutions for obtaining high-quality granules and guarantee results.