In recent months, we have received an email from the company from Finland. Company name - Nordic Bulk Oy, which is mainly engaged in production Ammonium sulfate. Currently valid Ammonium sulfate line Annual performance about about 90 000 ton. The company wants to build a new compact production line by annual performance 100 thousand tons. Therefore, we were sent an email with a question, Can we put a fully equipped compact production line. After discussion with engineers, we provided them with a production line, corresponding to their needs, namely Two -vault line of extrusion granular.

What decisions for production lines do we provide them?

After discussing with many engineers, we developed a line for the production of two -wound extrusion granulators, which will help her achieve annual performance in 100 000 tons of ammonium sulfate. The line for the production of roller extrusion granulation can press dry powder into granules. For ammonium sulfate, this is the most suitable production line for its production.

The production line for the production of anti -rollers is compact and reasonable, and the produced granules have high strength. All parts of the production line equipment, Contacting with materials, made from anti -corrosion And wear -resistant steel. Reduce the wear of your equipment and extend the service life of your equipment. Besides, This production line does not require drying and cooling processes, which significantly saves your costs.

What equipment includes a line for the production of roller granulation, which we have developed for his company?

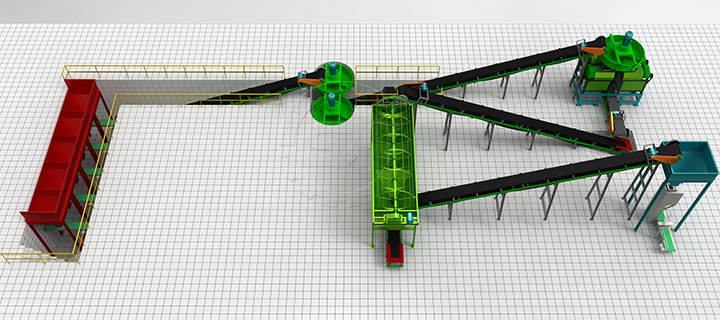

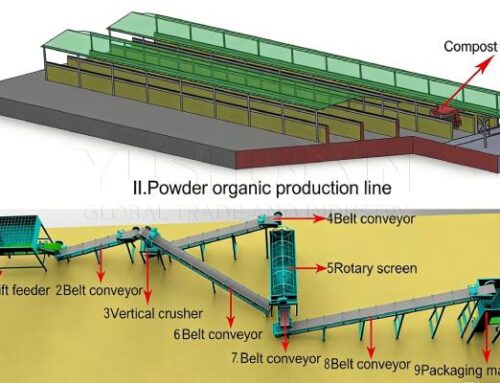

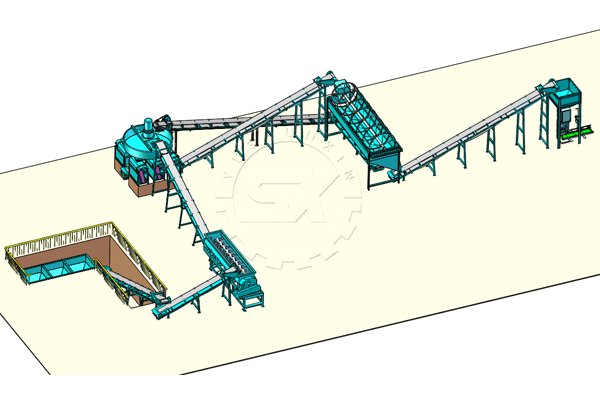

The main equipment in the production lines supplied by us includes Horizontal mixers, Roller granulators, sifting cars, Coating rotation machines, Automatic packaging machines And Palletite. After communicating with customers, we added Roting dryers And rotary coolers In accordance with their requirements. Besides, For transportation are used Ribbon conveyors.

Among the entire production line of granulation with two rolls, the most important is the granulator with two rolls in the granulation process. To satisfy the annual production need for 100 000 ton, We increased the number of granulators with oncoming rollers in the design to four. To do this, a model of the two-wound granulator SXJZ-3T was chosen. Its annual production capacity is 3 Tons, and the size of the produced particles is from 3 to 10 mm.

What are the advantages of the production of ammonium sulfate using the production line of roller granulation?

The composition of the raw material is flexible, And the routes of raw materials, which can be produced, broad. Currently, there are more 20 types of materials, which are successfully used for extrusion granulation. Besides, The process of extrusion granulation allows you to flexibly change the formulas of products in a very short time, and one set of equipment can produce products with more than 30 formulas. In other words, You can use it for the production of other complex fertilizer products.

Generally, The line of extrusion granulation can be considered as a production model with low investments, low level of pollution and high profit in the fertilizer production industry. This production line is also more suitable for the company for the production of ammonium sulfate.