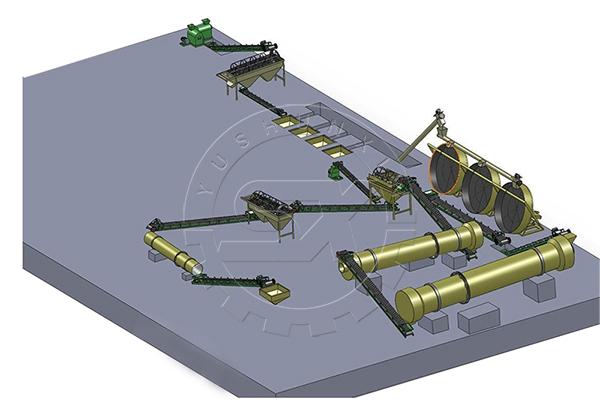

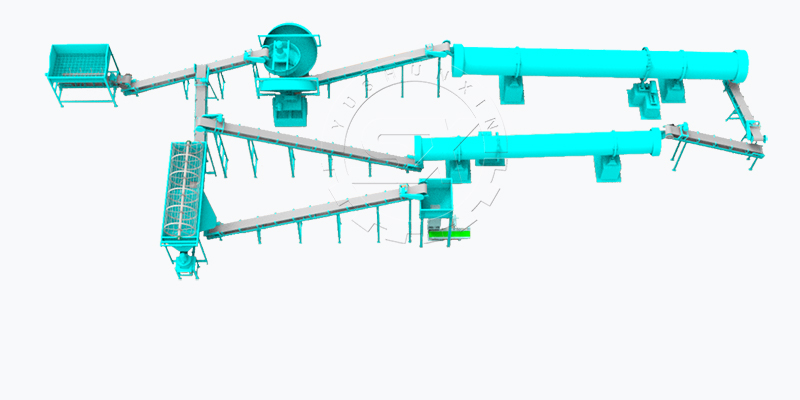

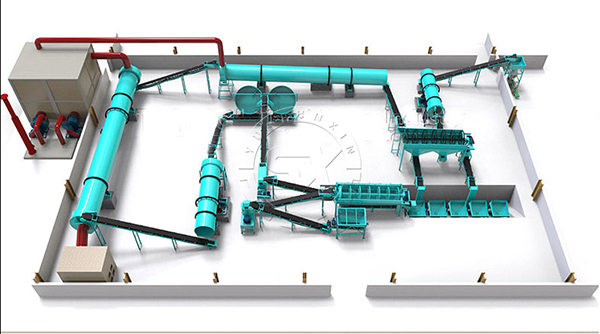

Solution: Disk granulation line

- Performance: 1-30 tons/time.

- Price: 390 000 rub. – 66 000 000 rub.

- Raw materials: Manure, peat, brown coal, nitrogen, phosphorus and potassium,…

- Scope: Production of organic fertilizers from livestock and poultry, brown organic fertilizers, NPK, phosphorus fertilizers…

- Production line process: Crushing, mixing, granulation, Drying, cooling, sorting, Coating, package…

Disc granulation line Suitable for various materials. Including cattle and bird manure, Agricultural waste, Coal powder, cement and chemical fertilizers and t. e. Especially in the production of complex fertilizers. You can use our production line for the production of high -quality complex fertilizers NPK, fertilizers DAP and T. e. Our production line of disk granulation has a simple design, low price and low operating costs. It provides continuous work with high performance and is suitable for large -scale production needs. This is an ideal solution for obtaining high -quality and high -yielding complex fertilizers. Our line for the production of disk organic fertilizers includes: crushing, mixing, granulation, drying, cooling, Sorting, Coating, Packaging… If you have needs or you want to know more, Contact us.

What raw materials for complex fertilizers are suitable for use on the production line of disk granulation for you?

Raw materials for the production of complex fertilizers are urea, Ammonium chloride, Ammonium sulfate, liquid ammonia, Monoammonyfosphate, Diammonyphosphate, potassium chloride, potassium sulfate and some fillers, Such as clay.

- Nitrogen fertilizers: Ammonium chloride, AMONIA SIMANDAGE, AMONIA SIMANDAGE, urea, Calcium nitrate and others.

- Potassium fertilizers: Sulfony kali, Plant ash and others.

- Phosphorus fertilizers: Calcium superphosphate, Double superphosphate, Calcium-magnesium-phosphate fertilizer, phosphorite powder and t. e.

What production equipment do you need to use in the full production process?

The first is a composting machine, which must be used in the process of fermentation. You can choose the right composter in accordance with your needs. Then you will also need a dosage warehouse for accurate dosing of raw materials. A vertical shredder will help you grind the material to size, suitable for granulation. A mixer will help you evenly mix all types of mixed materials.

For the granulation process, you need to use a disk granulator, dryer, Cooling car, Rounding machine, sifting a car, coating machine and other equipment. For the final packaging process, all, What do you need, - These are packaging scales and layers on pallets.

How do you produce organic and inorganic fertilizers using a granulation disk line?

First of all, You need to skip high -quality organic raw materials, such as nitrogen, phosphorus, potassium and other fillers, through a stationary mixer and evenly mix it. Then it is sent to a vertical crusher for grinding. Crushed material is evenly added to the disk granulator. The binder or the corresponding amount of water is sprayed onto the material in the disk through the water -spraying device of the disk granulator and is agglomerated into balls.

Why choose a disk granulation line for the production of complex fertilizers?

For the production of complex fertilizers, the line for the production of a disk granulator is effective and practical. The equipment has a compact design, high degree of automation and simplicity of operation, Suitable for mass production of complex fertilizers.

All equipment is made for you from corrosion -resistant and wear -resistant materials. In this production process there is no three -time waste discharge, What is energy -saving and environmentally friendly.

Besides, This line of disk granulation can not only produce complex fertilizers of high, medium and low concentration, but also produce organic fertilizers, Inorganic fertilizers, Biological fertilizers, magnetic fertilizers and t. D. can say, that it is multifunctional.

What technological requirements do you need to fulfill in the process of production of organic and inorganic fertilizers on the disc granulation line?

There are questions in various processes, requiring your special attention. Below we will briefly introduce you a few points.

- Tonin of raw materials.

You need to grind organic raw materials to the size of less 100 oven, so that the size of the particles of the produced granular fertilizer does not differ too much.

- Tilt of granulation.

You can arbitrarily adjust the angle of the disk granulator in the range of 45–55 °.

- Granulation.

During the initial load and granulation, you must verify, that the disk has a powdered return material in size less or equal 1 mm as a uterine mixture for participation in granulation. When granular, you must fully use the strength of the viscosity of the material itself, so that the material is granular with the rotational drive of the disk.

- Stable feeding.

If the feed volume is too large and the material rolls in the disk for a short time, The particles of the ball will be too small and fragile, and the performance will be low and they will be easy to grind. However, when the amount of material submitted is small, prone to the appearance of large particles. Therefore, it is necessary to ensure continuous stability of the supply throughout the entire production process.

Why should you choose a disk granulator instead of other granulators?

The process of granulation disk granulator You can see intuitively. You can be aware of the equipment at any time and adjust it in time, if you find something abnormal. The size of the particles of the finished product depends on the angle of inclination and the speed of the disk rotation, In this case, the slope speed and the speed of rotation of the disk can be adjusted. Thus, You can control the size of the granulator of the disk granulator. The process of disk granulation has a wide range of particle size control, high adaptability and very high ball formation rate, which can reach more 93%. This is very good equipment for the production of complex fertilizers. Certainly, If you need it, We can also replace it with other granulation equipment for you.

You can contact us by e -mail, To learn more the line for the production of disk granulation.