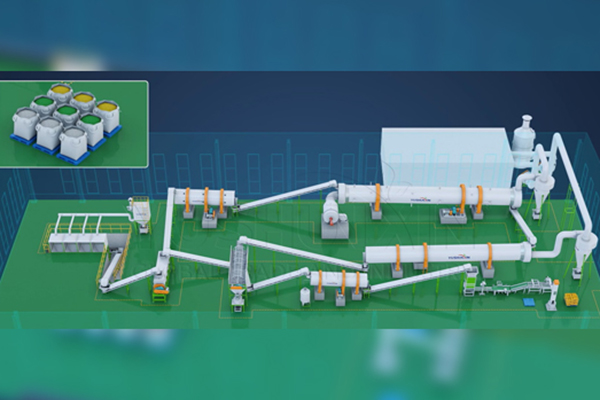

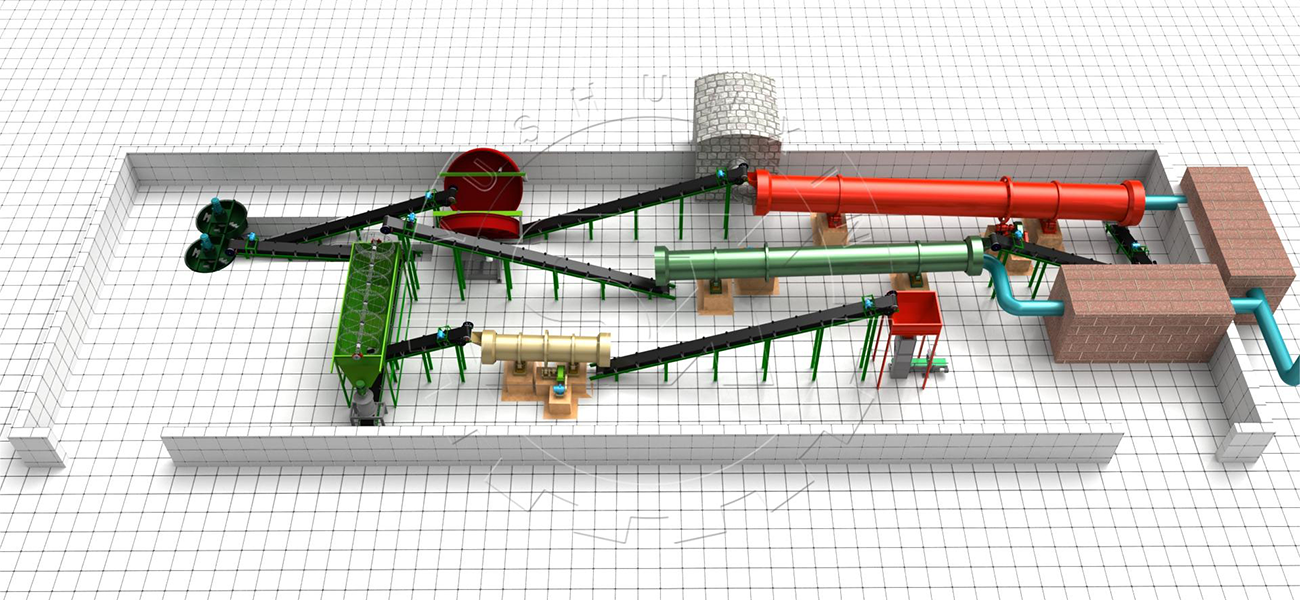

Solution: NPK Fertilizer production line

- Performance: 1-30 T/hour.

- Price: 390 000 rub. – 66 000 000 rub.

- Raw materials: Nitrogen, phosphorus, potassium, Microelements…

- Scope: Production of complex fertilizers…

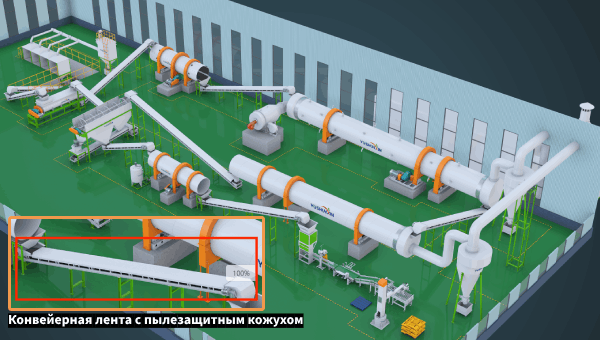

- Production line process: Dosage, crushing, mixing, granulation, screening, Coating, package…

The line for the production of complex fertilizers is a special complex of equipment, allowing automated and large -scale production of high -quality complex fertilizers. Our line for the production of complex fertilizers includes automated dosing stages, mixing, granulation, Drying, cooling, begging, Packaging and other stages. It is suitable for continuous production of various complex fertilizers of NPK and organo-neoorganic complex fertilizers. The entire production line is distinguished by advanced technologies, high degree of automation and ease of operation and maintenance. An effective increase in the efficiency of the production of complex fertilizers and product quality.

Investments in our line for the production of fertilizers of the NPC not only effectively increase the productivity and quality of products, but also significantly reduce labor costs and energy consumption. Help your company to achieve energy conservation, environmental protection and efficient production. No matter, Are you building a new factory, modernize the existing production line or expand the power, We can develop a comprehensive, an effective and reliable solution for the line for the production of complex fertilizers. Contact us for discussion. Welcome, Contact us by e -mail.

If you want to invest in the NPK fertilizer production line, What equipment do you need to buy for this production line?

Investments in the line for the production of complex nitrogen, phosphorus and potassium fertilizers is a complex project, including many links. You need to think over the entire production process: from primary processing of raw materials to packaging and storing the final product.

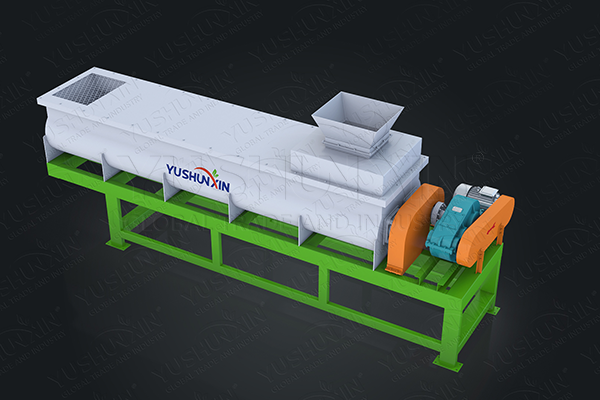

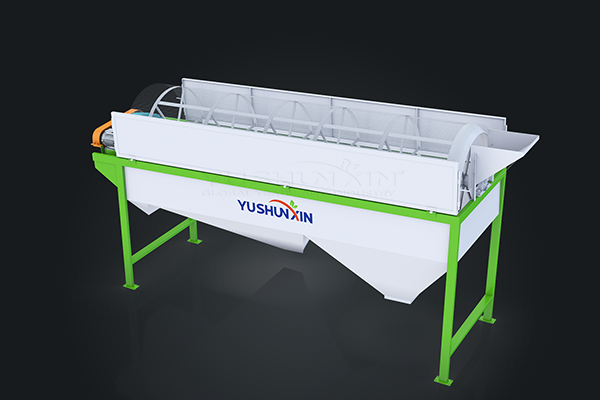

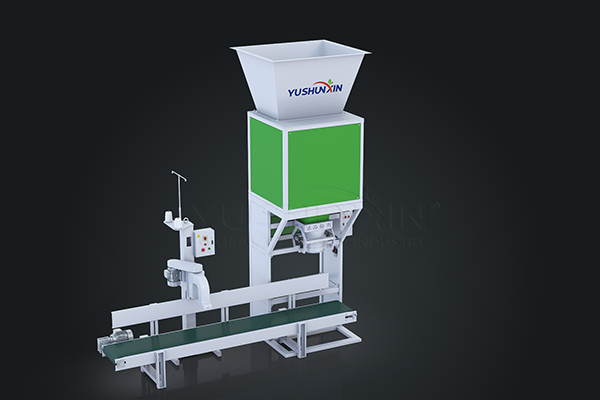

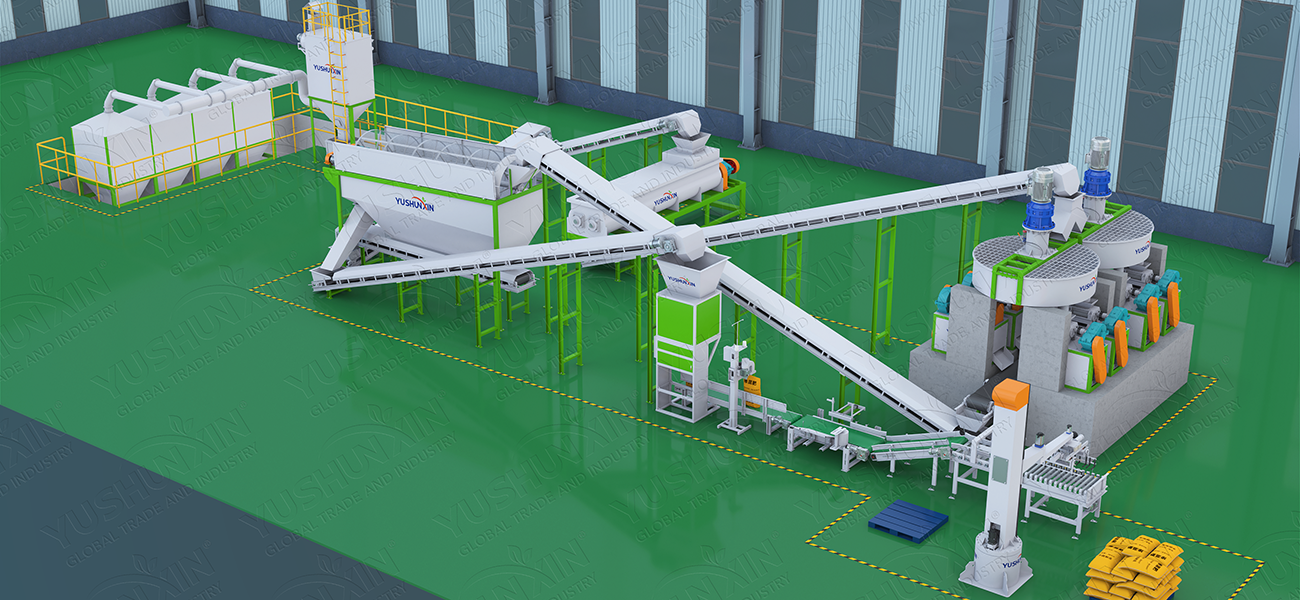

Firstly, You need a system for storing raw materials of sufficient capacity, For example warehouses and bins. This follows the exact dosing system, providing mixing ingredients in the correct proportions. Mixing equipment serves to complete mixing of prepared raw materials. Next is the granulation equipment, which compress mixed raw materials in solid granules. Dryers and cooler are used to remove moisture from pellets and cool them to a safe temperature, respectively. Sifting machines are used to separate quality particles. Finally, The packaging machine packs fertilizers for the convenience of transportation and sale. This equipment works effectively together, producing high -quality NPK fertilizers for you.

To build effective, Environmentally friendly and economical production line of the NPK fertilizers, You will need something more, than just scientific design and layout. It is also necessary to invest in a series of high -quality equipment, to ensure the uninterruptedness of the entire production process and excellent product quality. Shunxin can develop a layout of your production line for free. We have more 20 years of production experience, and our quality is guaranteed!

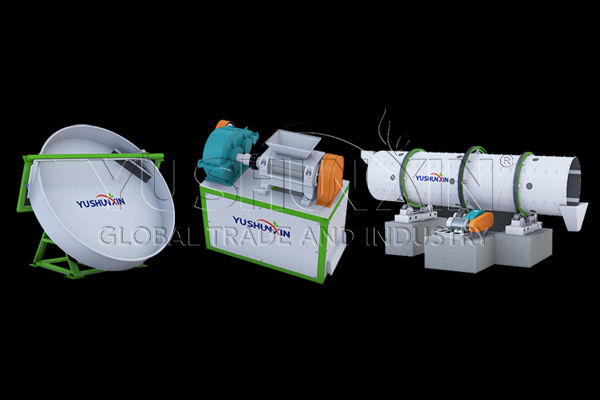

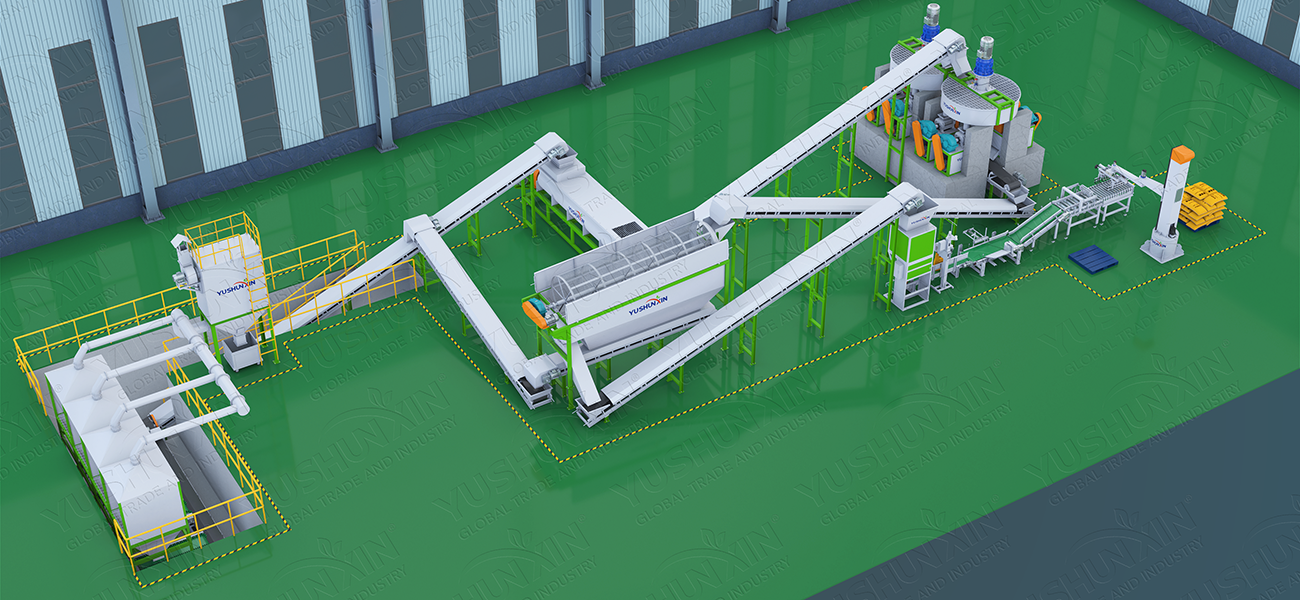

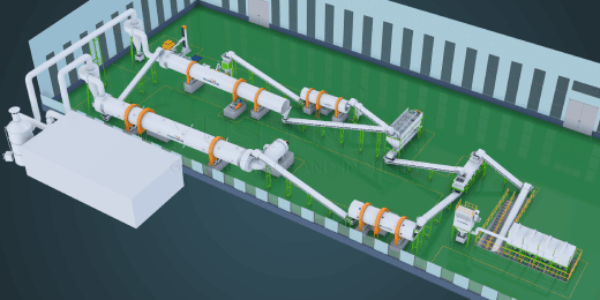

Our factory offers you three common universal solutions for granular NPK-approval.

Miscellaneous raw materials in granulation projects requires different solutions. However, the universal line of granulation of complex fertilizers allows you to produce a wide range of complex fertilizers. Our granulation line of complex fertilizers is flexible and compatible with other types of production of complex fertilizers. Such as organo-neoorganic complex fertilizers, fertilizers with controlled release, Mineral fertilizers and t. e. This significantly expands the range of your products and meets your needs in the diversification of products. In ours Shunxin The most popular granulation lines among customers are: Tarelcum granulation line, Drum granulation line and roller granulation line. If an individual granular line is required for the product you need, You can contact us for individual design.

Granulation line with two rolls.

Disk granulation line.

We have rich experience in the industry and a professional technical team. We can develop for you the most suitable granulation solution in accordance with the characteristics of your raw materials and requirements for the finished product. We recommend the optimal technological scheme and equipment configuration taking into account your specific requirements, such as the ratio of source materials, granulum strength and granulometric composition. Whether it is the construction of a new production line or the modernization of the old, We can provide you with a comprehensive solution from the design of the decision, manufacturing equipment, installation and commissioning until after -sales maintenance. Our equipment is stable, low energy consumption and high degree of automation. This will help you increase production efficiency and reduce operational costs.

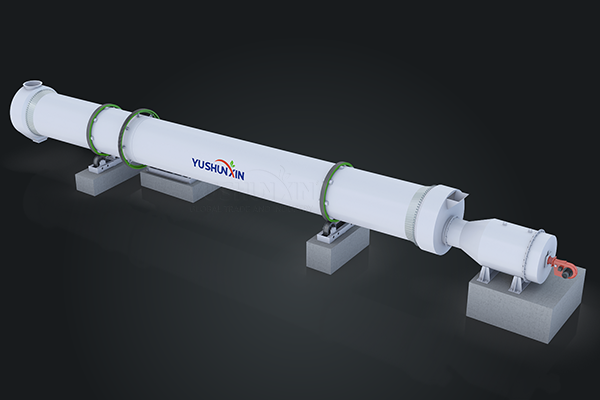

What line for the production of fertilizers of the NPK produces less dust pollution in the production process?

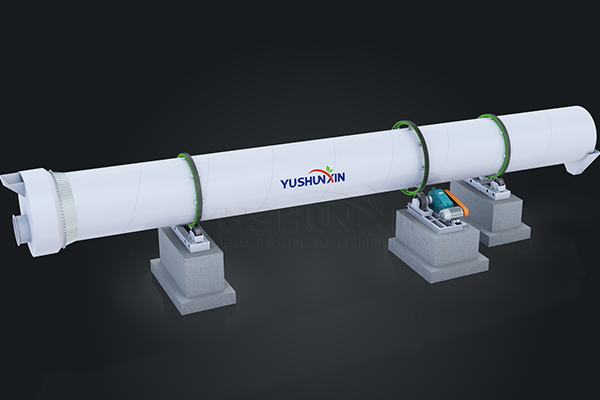

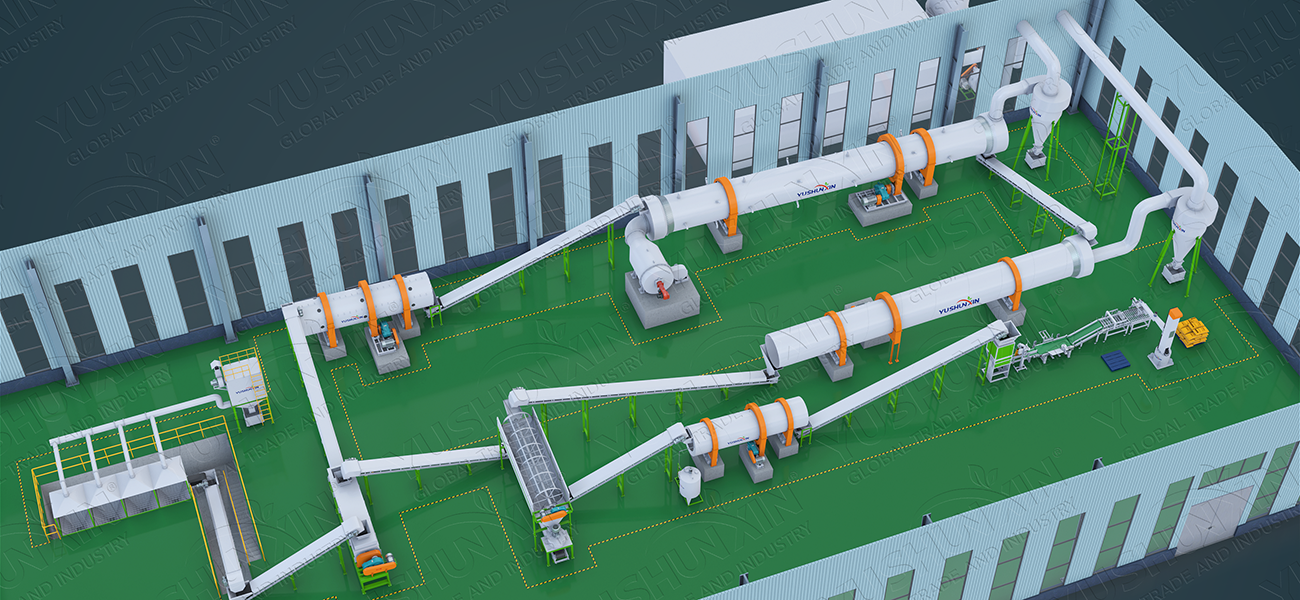

Among various production lines for NPK-approval granulation lines with a rotating drum, Undoubtedly, They produce less dust. This is due, First of all, those, that most of the production processes (mixing, granulation, Drying and cooling) carried out in a closed space. The material is in contact with the external environment only during transportation and other stages. The closed process effectively reduces the leakage and dispersion of dust. Compared to other methods of open granulation, This method is more environmentally friendly. If you want to minimize the amount of dust in production, You can install a dustproof casing on a conveyor tape (as shown in the image on the right).

Besides, In the process of drum granulation, the powder raw materials NPK are repeatedly mixed, Classes and is compacted in a rotating drum. Gravel production with even greater strength. The choice of a line for the production of fertilizers of the NPK with a rotating drum can significantly improve the quality of the finished fertilizer. If you want to produce highly concentrated granular NPK fertilizers effectively and environmentally friendly, Our granulation line with a rotating drum, Undoubtedly, will be your best choice.

Which of our equipment will help you improve the consistency of NPK fertilizers?

Automatic dosing silage is extremely effective equipment to increase the uniformity of the production of NPK-approval. Thanks to the accurate dosing function, automatic dosing silos can guarantee, that each batch of raw materials will be proported in accordance with the established ratio. This improves the consistency and quality of the product. Here are some advantages of automatic dosing silos in the production of NPK fertilizers:

- Accurate dosing: The dynamic dosing bunker can accurately weigh and dose raw materials in accordance with the given formula. This ensures the permanent composition of each batch of NPK-approval, Improving the quality and stability of the product. Effectively reduce the influence of the human factor.

- Improving efficiency: Automated systems can speed up the dosing process and reduce production time. Increasing the overall production efficiency.

- Reducing waste: Automated dosing systems can better control and use raw materials. Reducing the loss of raw materials and waste.

- Recording and tracking data: Our automatic dosing system is equipped with a data recording function. It can help you track the production data of each batch to control quality and improve.

If you want to produce slowly released NPK-approval, what equipment do you need to purchase and where to place it?

You need to purchase: Rotor coating machine and tank.

If you want to make NPK fertilizers with slow release, Before packaging, it is usually necessary to carry out the process of applying the coating. This gives fertilizer the properties of slow release. For this you will need Rotor coating machine and tank. This is effective equipment, specially designed for complex fertilizers.

The rotor machine for applying the coating uses a powder or liquid coating process. The added material of slow release is stored in the tank for applying the coating. The tank is located on the side of the rotor machine for applying the coating, And they are connected by a pipeline. NPK particles are covered with a protective layer through the loading hole, And then they roll and compact inside the machine. This effectively increases the hardness of the granules and prevents the clutching of complex fertilizer.

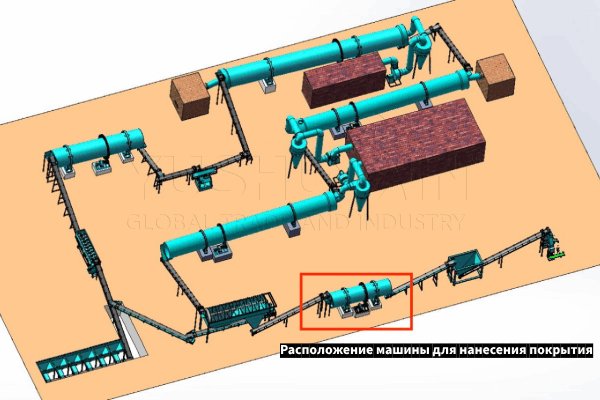

It must be placed: behind a sifting machine and in front of the packaging machine.

Why is the machine for applying a film coating should be placed behind the sorting machine in the process of the production line of the NPK fertilizer? Because the sifting car will return the non -inferior particles for repeated granulation. If the coating is applied before sifting, Fertilizer granules, granulation returned to the process, affect the overall composition of fertilizer. Placing a car for applying the coating after sifting guarantees, that the coating will be applied only to granules, relevant to the requirements. This not only saves coating material, but also provides the effect of slow release and the overall quality of the finished fertilizer.

What fertilizers with the NPK ratio are more popular in the market?

- 1

15-15-15 or 16-16-16, This is a fertilizer with a balanced NPK ratio. It is widely used by people, since it provides plants with balanced nitrogen nutrients, phosphorus and potassium.

- 2

20-20-20, Another balanced NPK fertilizer formula. It is usually used to grow various cultures, Such as vegetables, Flowers and fruit trees.

- 3

12-12-17+2MgO, This formula is rich in potassium. Suitable for the fruit ripening stage and helps improve the quality and ability to preserve the freshness of agricultural crops.

- 4

10-20-10 or 10-26-26, This formula with a high phosphorus content is suitable for the stages of planting and rooting agricultural crops. Contributes to the development and strengthening of the root system.

- 5

18-46-0 (Diammonyphosphate). This is not a traditional NPK formula, But the high content of phosphorus makes it very popular to prepare the soil before planting. Especially for cultures, requiring a strong root system.

- 6

30-10-10, especially suitable for plants, which requires a large number of nitrogen fertilizers to stimulate the growth of leaves. For example, lawns and sheet vegetables.

What raw materials can be used for you NPK fertilizers in these proportions?

NPK Fertilizer is a complex fertilizer, containing three main nutrients for plants: nitrogen (N), phosphorus (P) And potassium (K). For different types of NPK-approval, different raw materials are used. For reference below, some types of raw materials are given, Fertilizer usually used in the production of NPK.

- Urea (CO(NH2)2): is a widely used nitrogen source. High nitrogen content.

- Ammonium sulfate ((Th4)2SO4): Provides nitrogen and sulfur. The latter is also one of the important elements, necessary for plant growth.

- Ammonium nitrate (NH4NO3): High nitrogen content. Provides nitrogen, simultaneously increasing the acidity of the soil.

- Ammonia (NH3 · H2O): liquid ammonia. Can be used for direct introduction or as raw materials for other fertilizers.

- Monoammonyfosphate (MAP, NH4H2PO4): Contains phosphorus and nitrogen. This is a common phosphorus fertilizer.

- Diammonyphosphate (Duff, (Th4)2HPO4): marry. Also provides nitrogen and phosphorus.

- Calcium superphosphate (SSP, Ca(H2PO4)2): more traditional phosphorus fertilizer. Contains a smaller share of phosphorus.

- Trikalcium phosphate (TSP, CA5(PO4)3OH): Highly phosphorus fertilizer.

- Phosphate ore (phosphate ore): The raw materials found in nature for phosphorus fertilizers. Chemical treatment is usually required to improve its solubility.

- Potassium sulfate (K2SO4): Provides potassium, as well as sulfur.

- Potassium chloride (KCl): also known as potassium fertilizer. This is one of the most common potassium sources.

- Nitrate potassium (Kno3): Provides as potassium, So is the nitrogen.

- Potassium magnium sulfate (K2SO4·2MgSO4): At the same time provides potassium elements, sulfur and magnesium.

- Microelements (such as copper Cu, zinc zn, Iron Fe, manganese mn and t. e in.): Microelements can be added in accordance with the needs of the soil and agricultural crops.

- Fillers (For example, limestone powder): used to regulate the size and weight of the fertilizer particles.

- Stabilizers and anti -peeling: used to improve the physical properties of fertilizers, prevention of tracking and maintaining stability.

When you choose a manufacturer for the purchase of equipment for the NPK fertilizer production line, What you need to pay attention to?

By purchasing equipment for the production of fertilizers NPK, It is especially important for you to choose the equipment manufacturer. A good manufacturer can save you a lot of effort. To guarantee, that you will receive high -quality and effective production equipment, It is necessary to take into account several important factors.

Good after -sales maintenance is crucial. Make sure, that the manufacturer offers comprehensive technical support and services to quickly eliminate problems. Learn about their additional services.

Each fertilizer production process has its own unique characteristics. You need to choose a manufacturer, which can provide you with individual solutions, based on your specific production needs.

Fertilizer production equipment should withstand long -term and high -intensity operation. You can ask the manufacturer to provide you for reference some cases from past customers.

7 questions and answers about purchasing NPK particle production lines.

Having more than 20 years of experience in the industry, Shunxin provided professional decisions on the design and implementation of production lines Many international clients. We focus on the production of effective equipment for the production of NPK-approval and strive to help you realize your ambitions in the field of fertilizer production. If you are interested in the implementation of investments in the line for the production of NPK fertilizers, Please, Contact us.

We promise to use our rich industry knowledge, to develop an effective production line for you free! We invite you to visit our production complex, where you can personally check the quality of the equipment and meet with the leadership.

Frequently asked questions on the NPK Fertilizer production line.

Sulfuric acid plays many roles in Fertilizer NPK production (nitrogen phosphorus). Sulfuric acid not only participates in reactions as raw materials during the production process, but the sulfur itself is also one of the important nutrients, necessary for plant growth. However, when using sulfuric acid, some problems arise. For example, its corrosion activity in relation to equipment and the environment. and the risk of environmental pollution, caused by a leak sulfuric acid during the production process. Therefore, you need to reasonably control and reduce the use of sulfuric acid, look for alternative raw materials and optimize the production process. This has become an important area of research in the field of NPK fertilizer production.

So, What methods can be used to reduce the amount of sulfuric acid, Fertilizer production used in the production of NPK?

You can reduce sulfuric acid consumption, Having optimized the production process. This may include adjusting the ratio of raw materials, increasing the efficiency of equipment and increasing the level of control of the reaction process. And the use of more advanced catalysts to increase the speed and selectivity of the reaction.

In some cases, you can look for alternative raw materials, Using sulfuric acid for the production of NPK fertilizers. For example, Sulfant -containing minerals, Such as phosphogyps (STODURE PRODUCT SULFATE CALCTION), used to replace part of sulfuric acid, to ensure the need for Sery.

In the production process, sulfur -containing by -products may form. You can process these by -products and re -use them in the production process. Allows you to reduce the need for fresh sulfuric acid.

Using anhydrous production processes or steam granulation technology, it is possible to reduce or exclude the use of sulfuric acid. For example, NPK granules can be obtained by physical mixing (Two -wool granulator), not a chemical reaction. Thereby reducing the dependence on sulfuric acid.

Having improved the system of recovery of thermal energy and materials, You can reduce the additional consumption of sulfuric acid, caused by energy waste.

The use of raw materials of higher purity can reduce the increased consumption of sulfuric acid due to purification from impurities.

Large -scale production can reduce sulfuric acid consumption per unit of production due to the effect of an economic scale.

In accordance with market demand and demand for the crop, you can properly adjust the proportion of each element in the NPK formula. Can help you reduce the use of sulfuric acid.

Before taking any action, You need to carry out a complete analysis of costs and benefits. Make sure, that your new method of production or material not only reduces the consumption of sulfuric acid, but generally economically justified. No loss of product quality and other environmental costs.

Microelements in fertilizers (also known as microns) - These are elements in fertilizers, which are necessary for agricultural crops, but required in smaller quantities. Such as iron (Fe), zinc (Zn), Manganese (Mn), copper (Cu), the brown (B), Molybden (Mo), chlorine (Cl) and t. e. Want to know the sources of microelements? We divided the sources Complex fertilizers With trace elements, containing trace elements, In the following categories. For your information.

Complex fertilizer with trace elements.

| Elements | The main sources of fertilizers |

|---|---|

| Iron | Iron sulfate, Iron citrate, iron ore powder, Edt iron, Feces of animals and t. e. |

| Zinc | Sulfate zinc, oxide zinc, Zinc ore powder, Zinc Edt, industrial by -products and t. e. |

| Manganese | Manganese sulfate, Manganese oxide, manganese ore powder and t. e. |

| Copper | Copper sulfate, copper oxide, Halkin, Copper Edtu and T. e. |

| The brown | Storm, Boric acid, Bors -containing ores and others. |

| Molybden | Molibdat ammonium, Molibdat sodium, molybdenit et al. |

| Chlorine | Potassium chloride, sodium chloride, sea salt and t. e. |

Details the sources of trace elements in complex fertilizers for you.

Sources of mineral resources

- Natural ores: ores, Directly crushed or processed, are the main source of trace elements in many complex fertilizers. Iron ore serve as examples (Lemonite, hematite), Zinc ore (Revelerit, zinc sulfide and t. e in.) And manganese ore (Pyrolyusitis, Psilomelan). Copper ore (Halkin, Malachite, etc.. e in.). Bornaya ore (storm, Borage ore). Molybdenum ore (Molybdenite).

- Powder of phosphorite ore or potash ore powder, containing trace elements: sometimes also used as microns.

Industrial by -products and chemical products

- Speaking products of metal swimming: For example, by -products of electrolytic production of zinc, copper and iron. After cleaning and processing, they are used for the production of microfuits.

- Chemical synthetic products: The common chemicals include iron fertilizers, such as iron sulfate (Filed) And iron citrate. Zinc fertilizers, such as zinc sulfate (ZnSO₄), zinc oxide and chelatted zinc Edt. Manganese fertilizers, such as manganese sulfate (MnSO₄) and manganese oxide. Copper fertilizers, such as copper sulfate (CuSO₄) and copper oxide. Boron fertilizers, such as drill and boric acid. Molybdenum fertilizers, such as molybdate ammonium and molybdat sodium. Fertilizers, containing chlorine, such as sodium chloride and potassium chloride.

Organic sources

- Animals and plant residues: such as bone flour, Fish flour, Oil oil, Soy cake, bird droppings and other manure. These materials are rich in various trace elements. Despite the low content, Organic form is useful for plant assimilation.

- Guminic acid fertilizer: Guminic acid can form chelat compounds with certain trace elements, increasing the degree of assimilation.

Combined and lecture products

- Combined microelene fertilizers: They are made by combining several trace elements in a suitable ratio to ensure a comprehensive nutrition of plants.

- HELENT microelene fertilizer: Microelements are connected to organic helating agents (Such as Edta, DPA, etc.. e in.) for the formation of helates. Improves the stability and accessibility of elements for easier introducing to the soil or top dressing.

Other sources

- Industrial waste: such as melting slag, flying ash and t. e. After processing, they can also be used as raw materials for the production of microelene fertilizers. However, it is necessary to prevent excess of permissible norms of the content of harmful substances.

If you are interested Production of complex fertilizers, containing trace elements, Contact us for consultation. We are a professional manufacturer of equipment for the production of fertilizers. Delivery of a full set of equipment of the production line: from automatic dosing, mixing, granulation, Drying to intellectual packaging. Supports many formulas and individual settings of production capacities to satisfy your production needs in various types of complex fertilizers and microelene fertilizers. To get detailed information about products, get a commercial offer or make an appointment for a visit to the plant, Contact us by e -mail.