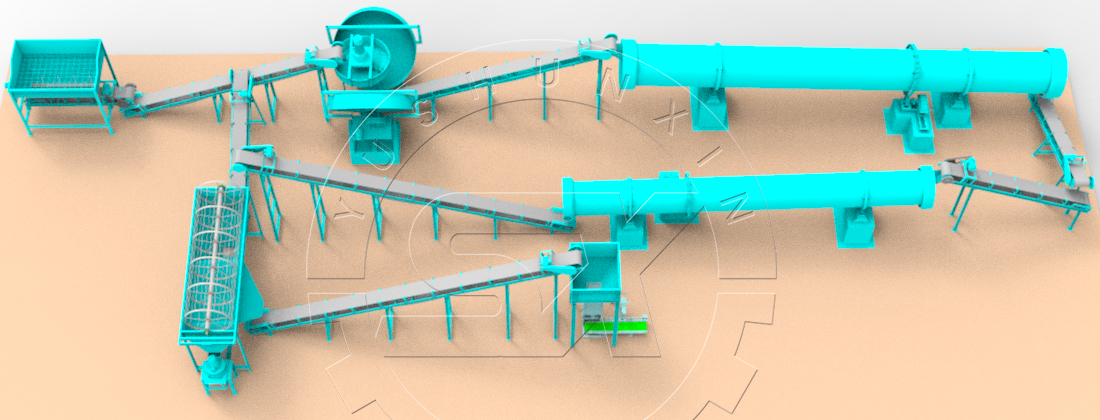

Disc Granulator Production Line Suitable for Complex Fertilizer Production and can produce high quality complex fertilizers with significant productivity. Next you will get acquainted with the production disk granulator line performance 5 subject. This granulation line is suitable for some medium-sized complex fertilizer plants.

What kind of equipment does this disk granulation line consist of for you? 5 subject?

Disc granulator production line is efficient and practical, has a good equipment structure. If you want to achieve production capacity 5 subject, This production line should consist of the following equipment.

This equipment is computer controlled and will allow you to perform the most accurate dosing of various raw materials. This is one of the necessary devices for the production of high quality complex fertilizers.

Will help you completely mix different materials in good proportions. Guarantee the quality of the complex fertilizers you produce. In the entire production line, this equipment is located above the granulator.

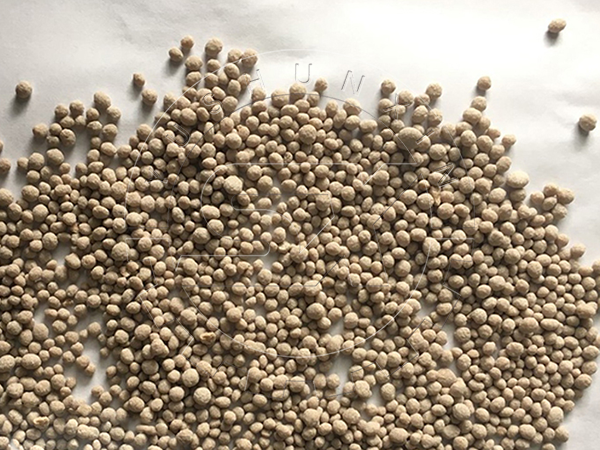

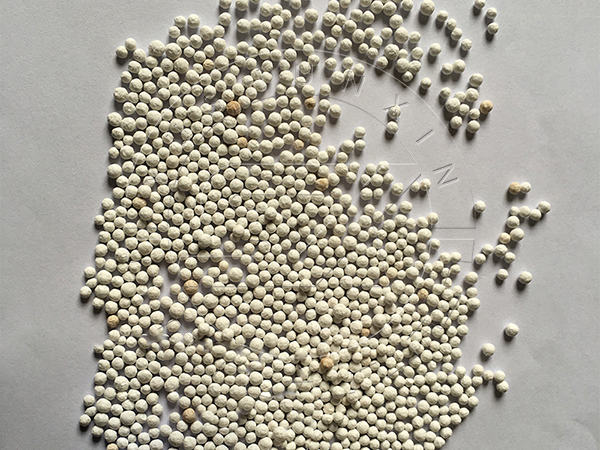

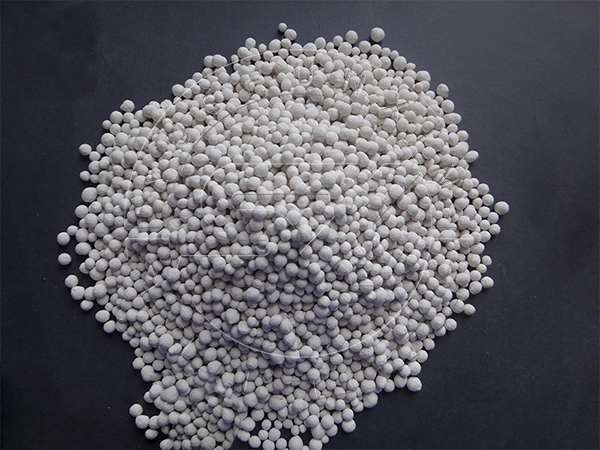

The mixer evenly feeds the material into the granulator. Thanks to the continuous rotation of the granulation plate and the spray device, the materials are evenly glued to each other, forming particles of uniform and beautiful appearance.

The dryer allows you to evaporate excess moisture from the granules you create. This increases the strength of the particles. The cooler allows you to quickly reduce the temperature of the dried particles to facilitate subsequent work.

Package – this is the last process in the complex fertilizer production line. High degree of automation allows for accurate weighing. And it's more efficient, than manual packing.

The above is for reference only. You can wisely add, replace or reduce some non-essential equipment, Based on your specific circumstances. After all, everything should be based on reality. If you have any questions about the production line configuration, you can send us an email, to contact us. We will have professional engineers, who will provide you with reasonable solutions.

What complex fertilizers can be produced on a disk granulation line with productivity 5 subject?

Complex fertilizers play a vital role in balanced fertilization. This not only increases the efficiency of fertilization, but also contributes to stable and high crop yields. This granulation line can produce various complex fertilizers.

For example:

- Monoammonyfosphate. Monoammonium phosphate is suitable for all types of soils and crops, can be used as a basic fertilizer, seed fertilizer and top dressing.

- Diammonyphosphate. Diammonium phosphate can be used to fertilize various types of soils in rice fields and drylands.

- Boromagnesium fertilizers. Suitable for agricultural rice fields, vegetables, fruit trees, etc. e.

- Ammonium nitrate. Ammonium nitrate often exists in granular form and can dissolve quickly when exposed to moisture, thereby releasing nitrogen, nutrient, necessary for plant growth.

What are the advantages of this disc granulation production line 5 subject?

The granulation process of this complex fertilizer disc granulation production line is intuitive. You can adjust the particle size at any time depending on the condition of the particles. Besides, This granulation line has a wide range of particle size adjustment, high adaptability and high clumping speed.

The whole production line does not include a lot of equipment, and the production process is short. Less investment in equipment, than other production lines. And it can achieve mass production and is more cost-effective.

For the manufacture of equipment, used on your production line, We use wear-resistant and corrosion-resistant materials. Less maintenance options, maintenance costs are relatively low, and the service life is long.

If you want to know more about this disk granulation line with productivity 5 subject, You can contact us below. Our professionals will answer your questions in detail!