Rotary drum churning granulator

- Type of equipment: Equipment for granulation

- The materials used: Organic fertilizers, Complex fertilizers, Mixed fertilizers.

- Brand: Shunxin Machinery

- Production capacity: 5-8 (subject)

- Product: Brand new

- After -sales service: Settings and installation, Debugging, Technical leadership

- Direct sales from the plant: Yes

Our Complex granulator of a gear drum, also known as the granulator "two in one". This is a dual granulator, which can directly granulate raw materials for fermentation. He combines the technology of wet granular granulator granular granular with the technology of wet granular granulator granular granulation technology. High -quality organic granular fertilizers can be made more efficiently.

How it works for you? After that, How do you send raw materials to the port of The strip conveyor, You first fulfill part of the principle of mixing tooths. The cutting head of the alloy at the top of hundreds of mixing teeth inside the equipment will be rubbed against the internal wall of stainless steel, To forcibly turn your material into granules-semi. Then enter the alarm granulation section. Your semi-finished granulas will be subjected to secondary granulation in the drum granulation section, And the final product - fertilizer in the form of spherical granules will flow out of the unloading hole. Your high -quality organic granular fertilizer is ready, and the whole granulation process takes about 3-5 minutes.

The hardness of granular fertilizer, the mixture with a drumstick produced by our granulator, better, than hardness, produced disk granulator and a drum granulator. Thanks to that fact, that organic particles can interculate and grow up under the influence of a certain force, You do not need to add additional binders when using the two in one granulator for granulation. And the finished granular fertilizer can be sifted directly, which significantly reduces energy consumption when drying.

What are the requirements for the humidity of your raw materials for our granulator with a gear drum with a stirrer?

The humidity of your granular material is about 30%. Generally speaking, the moisture content in the material drops approximately to 30% After fermentation. In other words, After fermentation of the material, it can be granulated directly using a granulator with a stirring gear drum. Moisture content of the finished granular fertilizer, produced for you, It is about 15%-20%.

How much high -quality organic granular fertilizer can our mixing granulator with a drum mixer per hour can produce for you?

Our granulator of a mixture with a rotating drum with a stirrer is suitable for large -scale production and can produce for you 5-8 tons of organic granular fertilizers per hour. High -quality granular fertilizer, the mixture made by our granulator with drum mixing, not only has a way out 90%, but also has a share of large particles less 10%. Granular fertilizer, made for you, realizes the granulation of pure organic matter, and the content of the organic matter reaches 100%.

How do you control the diameter of granular fertilizer, produced by a granulator with a rotating drum?

The size of the diameter of the particles can be correctly adjusted depending on the amount of mixed material and rotation speed of the main shaft of the granulator “two in one”. When you reduce the number of mixed materials and increase the speed of spindle rotation, The diameter of the particles becomes smaller. vice versa.

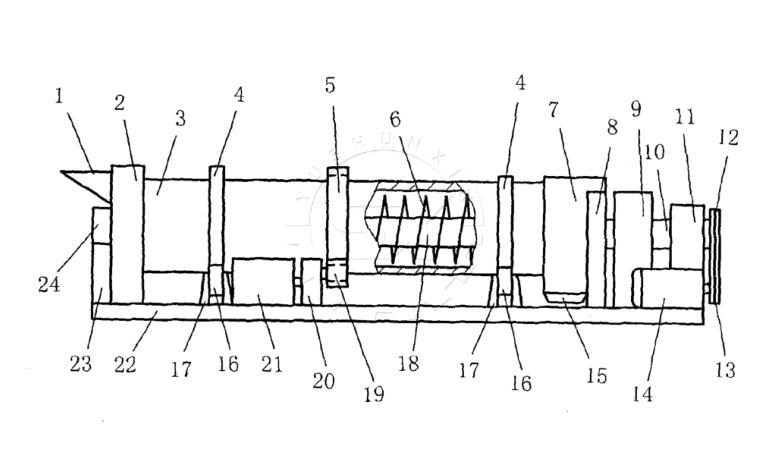

To give you a more complete idea of our granulatory mixer with a gear drum, Below is its structural scheme.

1.Inlet 2. The end cover of the outer steel cylinder 3. External steel cylinder 4. Two caterpillar wheels 5. Rosted crown. 6. Spiral chain of pellets rod 7. The output cover 8. The support of the shaft of the cylinder 9. Overload protection device 10. Power shaft 11. TECHER 12. Pulley 13. Leading pulley 14. Engine 15. Supervision pipe 16. Boor wheel 17. The roller bracket 18. The shaft of the cylinder 19. Gear 20. Reducer of the external steel cylinder 21 The drive of the outer steel cylinder 22 Rail 23. The bracket of the end of the tubular shaft 24. Bearing nest.

What production processes are used in our granulatory mixing drum with a stirrer, to make its use more convenient?

For the hull of the gear spindle with a gear drum, we use a thickened seamless steel pipe, And the cutting head uses a cutting head of alloy steel for you. These materials are very durable and durable, It is not easy to deform them, which reduces the loss of your equipment and reduces your production costs.

Besides, We fixed the transmission part and the case of the granulator of the mixture with a gear drum on the same frame. Moreover, that the installation is very convenient, but also a very strong design, thanks to which the “two in one” granulator works for you without failures.

What should be paid attention to when using a complex granulator of a gear drum, to extend the service life of the granulator "two in one"?

You need to regularly add oil to the seats of the bearings at both ends of the granulator of the mixture with a mixing toothed drum, To prevent rust. Each time before starting the car, it is necessary to check, Whether the anchor bolts of the gear-transmitting drum of the compound-granulator are tightened, Whether three -phase engine power, whether the wiring is walled up and t. e in., to ensure uninterrupted operation of equipment. The most important point is, What every time, When you use it, You need to open a granulator first, and then fill the material.

As for the price of a mixing granulator with a gear drum, which bothers you the most, Various configurations will lead to a price difference, And we can guarantee, that we will give you the best price. Besides, Our granulator “two in one” is sold directly at our factory, And there is no intermediary, which would have.

Certainly,If you have special requirements for some parts of the granulator with a rotating drum, We can configure it for you, And, Of course, The price will also increase.

If you have additional questions about the granulator of the mixture with a gear drum and you want to consult, Call, We will definitely give you the most professional answer.