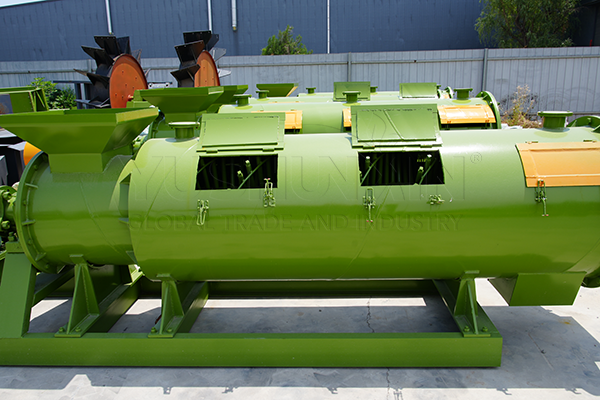

The customer from Uzbekistan had the idea to optimize the line for the production of organic fertilizers. It is planned to improve production capacity and product quality due to the introduction of modern granulator for manure. After a detailed inspection of several types of equipment, they, finally, they opted for the provided by us wet granulator with mixer SXJZ-1500. This machine is highly efficient and energy savings. Per hour can be produced 6-8 tons of high -quality pellets. Besides, The client also acquired SXPY-1500, The production capacity of which is 5-8 tons/hour, which additionally provides the shape and market adaptability of particles. This cooperation allowed Uzbek customers to achieve a quality jump in the production of organic fertilizers. If you have a need for equipment for the production of organic fertilizers, Contact us.

Why customers from Uzbekistan chose SXJZ-1500 manure granulator?

When choosing Grauling machines for manure Clients conduct a thorough market research and compare technical indicators. Finally decided to purchase a wet mixer granulator SXJZ-1500. This machine is characterized by the effective design of the teeth of the mixer, which allows it to process many types of organic materials. Effective pellet production can be achieved with lower energy consumption. Its unique wet mixing technology allows the material to be evenly loaded in the granulation process, forming granules with high density and stable quality. Customers in Uzbekistan used the new SXJZ-1500 organic fertilizer granulator for granulation, who not only improved the uniformity and stability of granules, but also reduced the coosiness of the material. This helps to improve the quality of the final product and makes subsequent storage more convenient.

What is the performance of the new SXJZ-1500 organic fertilizer granulator, acquired by customers in Uzbekistan?

The performance of the SXJZ-1500 is 6-8 tons in time. The ability to satisfy customer demand for high performance. It means, that customers can complete large -scale production of organic fertilizers in a shorter period of time. Increasing production efficiency, reduction in the production cycle and the possibility of more prompt response to market demand. Our effective equipment for manure for manure also helps customers in Uzbekistan to optimize the distribution of resources. Reducing the cost of a unit of product and increasing the competitiveness of products in the market. Allows Uzbek clients to quickly achieve the set goals for profit.

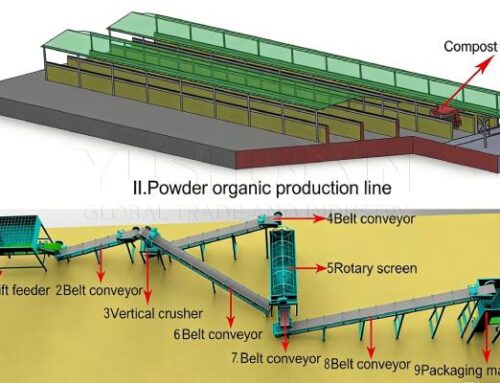

What other auxiliary equipment did customers from Uzbekistan get to optimize the line for the production of organic fertilizers?

For further optimization of the shape and texture of particles, the customer also chose a car for rounding the SXPY-1500. This equipment can give particles of organic fertilizers a homogeneous round shape. This guarantees, that ready -made granules of organic fertilizers will comply with high sales standards on the market. Round particles are not only more convenient for packaging and transportation, but also are more popular among end consumers. Help customers from Uzbekistan increase the competitiveness of their products in the market. The SXPY-1500 round-the-polish machine has production capacity 5-8 tons per hour and works perfectly with the SXJZ-1500. Synergy between them allows the line for the production of organic fertilizers of the Uzbek client to achieve ideal levels of performance.

In addition to the granulator with wet stirring, We also have Disk granulators, Roller granulators, Drum granulators And Other manure granulator On your choice. If you want to start a business or you have such ideas, as modernization of equipment, optimization of existing production lines and t. e in., Contact us.