At the beginning 2025 year, a well-known agricultural fertilizer company in Mali contacted us by email. They expressed great interest in NPK granulation lines with capacity 10 subject. And they also expressed hope to build a local plant for the production of complex fertilizers, having acquired a production line for granular complex fertilizers NPK 10 tons in time. Clients contact us, leaving messages on the site. Describe in detail the situation with raw materials, target production capacity and plant construction requirements. Our sales and technical teams responded immediately and provided in-depth communication tailored to customer needs. We developed a customized solution for a client in Mali and provided technical support and service throughout the entire process.

The process of design and communication with our client from Mali regarding a plant for the production of complex fertilizers.

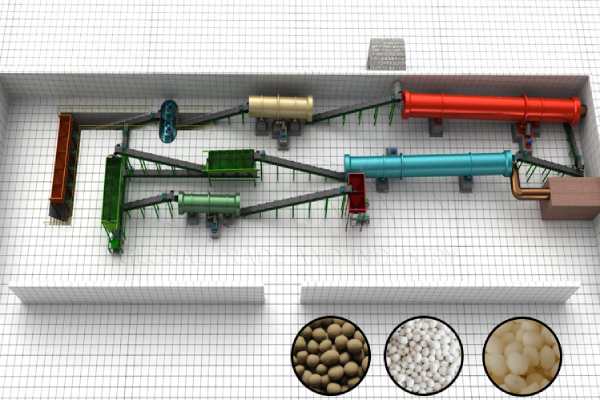

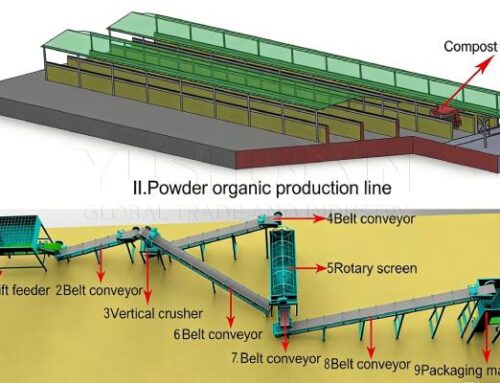

Upon receiving the request, our technical team immediately organized a video conference with the client. Get detailed information about the land plot for the plant, supply of raw materials, investment budget and other actual conditions. According to customer needs, we recommended mature drum granulation process. It is equipped with various equipment, including automatic dosing system, Drum granulator, rotary drying and cooling equipment, screening system and fully automatic packaging line. The overall layout is compact and easy to operate and maintain. To solve customer problems, related to energy costs, We recommend using a hot air coal stove in combination with partial electric heating. This significantly reduces operating costs.

Taking into account the different characteristics of raw materials, our engineers have also developed a flexible and customizable dosing software system, which allows you to guarantee the exact proportions of the final product. We have extensive industry experience and a professional technical team and can offer customized solutions, based on real conditions. Assistance in the smooth implementation of each client’s projects.

What are the features of the NPK fertilizer production line with productivity 10 subject, purchased by a customer from Mali?

Production line for granular complex fertilizers NPK capacity 10 subject, purchased by the customer for a plant producing complex fertilizers, custom made. It combines processes dosing, mixing, granulation, Drying, cooling, sifting and packaging of raw materials. It has the following key characteristics:

- High automation: the entire line is equipped with an intelligent control system PLK. It can automatically monitor and adjust production processes, significantly increasing production efficiency and product uniformity.

- Flexible formula: N content, P and K can be flexibly adjusted according to different crops and soil conditions. Exactly matched to local agricultural needs.

- Uniform granulation: The equipment uses advanced granulation technology. The finished product particles have a uniform size and low moisture content, which makes storing them easier, transportation and use.

- Energy saving and environmental protection: low energy consumption during production. Exhaust gas and dust emissions comply with environmental standards.

What we did to ensure rapid commissioning of our client's complex fertilizer production line in Mali?

Immediately before the equipment arrived, we sent three leading engineers to the site for two months. They provided comprehensive advice on installation and commissioning of equipment, and also helped the client complete acceptance of the production line. From the time the equipment arrived to commissioning, the project took only four months, which is a quarter of the industry average.

During this period, we also conducted training according to the “theoretical + practice». Provide tailored training to client teams. Including 30 first line operators, 6 maintenance specialists and 4 production manager. After the training, certification was organized, the passing score was 100%. Each trainee will be issued a certificate of completion of training.

If you also plan to implement complex fertilizer production project, Contact us. No matter, are you in Africa, Asia or anywhere else, we can design a customized NPK granulation line taking into account energy requirements, raw materials and market needs of your region. We provide full support at all stages of the process: from analyzing the feasibility of building a plant to supplying equipment, operation and maintenance.