Cage crusher

- Production capacity: 4~10 (subject)

- Type of equipment: Crushing equipment

- Applicable materials: Organic fertilizers, Complex fertilizers, NPK fertilizers, Complex fertilizer

- Brand: Shunxin Machinery

- Product: Absolutely new

- After -sales service: Setup, installation, Debugging, Technical leadership

- Technical leadership: Support

- Setup: Yes

- Direct sales from manufacturers: Yes

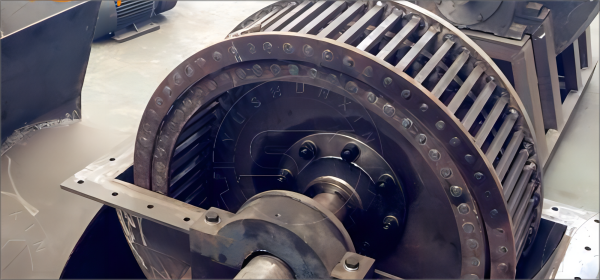

Cage crusher is a large horizontal crusher, which is widely used to grind complex fertilizers, crushing granules of complex fertilizers and fragmentation of fertilizers. It can grind various chemical fertilizers with moisture below 6% and suitable for grinding materials with relatively high hardness. This is a sworn enemy monoammonium, Diammonia and other solid materials. Usually used after drum sieve or granulator with a flat matrix.

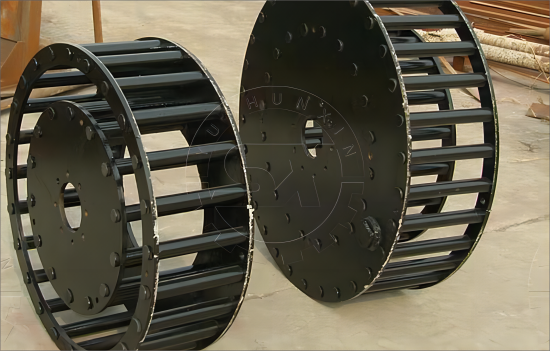

The machine is designed in accordance with the principle of shocking and uses a double -sided engine transmission mode. Your material enters the inner cell through the boot hole and enters the outer cage after crushing. The steel rod on the separator between the two rotating separators continuously affects the material back and forth, As a result, he is crushed. This method of crushing makes material powder more crushed, And the effect becomes better.

Investment costs for equipment for crusher cells are low, and the only wear -out details are rotor and lining, and other details can withstand prolonged use, And you do not need to often replace the details. And its installation is also very convenient. Thanks to the compact mechanism, it is easier, than other types of grinders with the same performance. As a result, space and foundation, which you need to install it, less. Вы даже можете установить его высоко над землей.

What types of cell crushers are currently on the market?

We divide the crushers of the cell into three categories depending on the size of the raw materials and the product of the product. These are rude crushing machines, Medium crushing machines and small crushing machines.

- The car of gross crushing is designed to crush material the size of 1500 mm-500 mm to 350 MM-100 mm.

- A medium -sized crushing machine can grind your materials with a size of 350–100 mm to 100–40 mm.

- The thin crushing machine is designed to crush material in size 100–40 mm.

You can choose depending on the size of the particles of your raw materials and the size of the particles, which you want to produce.

How our cell crusher performs grinding for you?

Your material will first get into the car through the loading hole, and then fall into the central part of the two opposite strokes. At this time, the material block will first fall on the most inner circle of steel rods. Due to high-speed rotation, the material will be crushed by a strong blow of a steel rod. Then he is under action centrifugal force discarded to the next ring of steel rods, and the material hits the same way on this ring of steel rods, but in the opposite direction. Continue in the same spirit until then, until the material goes through steel rods in each circle. In the end, You will get the final crushed material in the lower part of the casing.

What are the methods of crushing your material using our crusher with cells?

There are approximately three ways to grind materials in a crusher with a flower crusher.

The first is crushed by the blow of a steel rod, As mentioned in the section "How our cell crusher performs grinding for you". Secondly, Materials collide with each other.

During the process of crushing in the crusher, clashes between the materials inevitably occur, which leads to a certain crushing.

Third, hit the inner wall of the crusher of the cell and be crushed.

If you are not satisfied with the size of particles, crushed in a crusher, How to adjust it?

Very simple. You can configure the number of revolutions rotor, The thickness of the sticks, The number of roots and the number of layers, to configure the granularity of the final product. This adjustment range is very wide. And most of the crushed products - cubes.

Below are the main technical parameters cell crushers for reference.

What should be paid to when using our cell crusher, which can effectively extend its service life?

Our cell crushers are widely used by customers due to their simple design, strength, stable work and good grinding effect. To increase the service life of the crusher in everyday work, You must pay special attention to the following points.

To ensure the quality of crushing, it is necessary to strictly control the amount of each load at least 1/2 Box volume with material.

After prolonged use, If the belt is strongly worn out, and the hose is damaged or flows, it should be replaced in time.

At Launch of the motor First you need to give the car to work idle 1-2 minutes, and then gradually serve the material from the feed tray, Moreover, the feed should not be too fast or too large. If the material in the grinder is stuck and the engine does not rotate, Turn off the power immediately, delete the stuck material and continue to use it.

If during work you find an abnormal noise, stop the car immediately to check.

When performing super -frying, after completing the work of the grinding machine, the machine must continue to operate dry during 0,5 minutes, And the remaining materials should be sucked out.

Our company specializes in the production of garden crushers and equipment for the production of organic fertilizers, supporting production lines. Catcher-Brill, produced by our company, has an excellent crushing effect, and the sold cell-to-the-saucer was well accepted by many clients. If you want to know the effect of crushing your materials in a cell crusher, You can send your materials, And we will check the car for you. We have many years of experience in production of equipment and the full system of pre -sale and after -sales service. You can request or visit at any time.