In progress Production of cat filler granulator is one of the key devices. Filler for a cat toilet should have good adsorption, coagulation and convenience in circulation. To achieve these characteristics, it is very important to choose the right granulator.

GThe producer for the manufacture of a filler for a cat toilet must be selected in accordance with the type of filler for a cat toilet, which you produce. Such as bentonite, sawdust, Remains Tofu, Paper mass and t. e. And it is necessary to provide, so that the granulation process is effective and stable. Particles of a cat toilet, obtained in this way, can be homogeneous and have a strong coagulation ability. Based on these requirements, We count, that the following types of granulators are most suitable for the production of fillers for your cat toilet. You can choose a granulator for a cat toilet, which is right for you, depending on your situation.

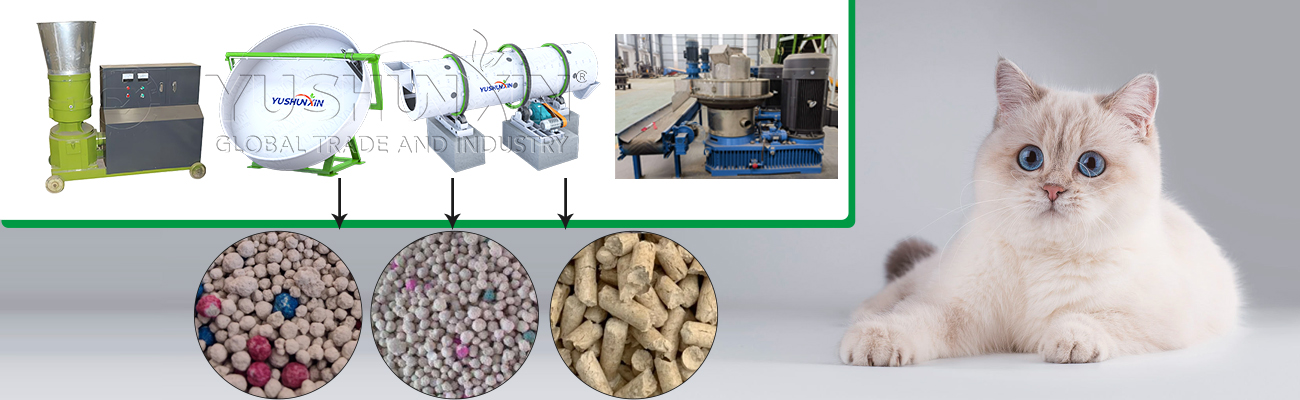

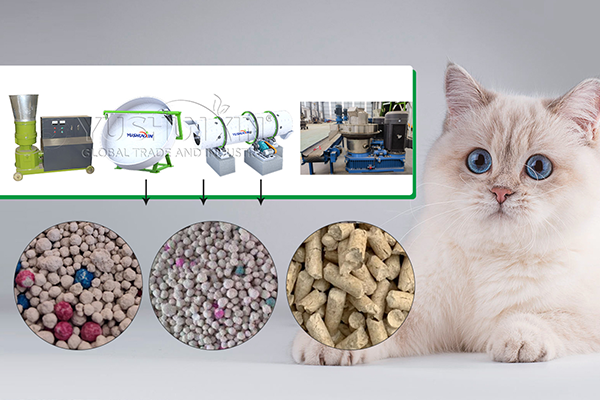

Disk granulator production of cat filler.

Disk granulator Suitable for the production of granular products, requiring certain strength and roundness. Adjusting the angle of inclination and speed of disk rotation, You can control the size and shape of the filler particles for the cat toilet. If you want to produce an filler for a cat toilet with a homogeneous particle size and a rounded shape, it will suit you more. For example, Bentonite filler for a cat's toilet.

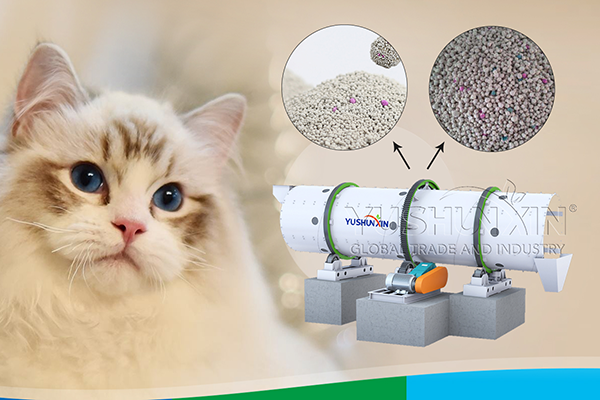

Drum granulator produces a cat filler particles.

Drum granulator Suitable for mass production of granular products for a cat toilet. He is able to control the size, The hardness and content of moisture in the formed particles of the cat toilet. Guarantee the uniformity and stability of the quality of the final products for cat toilets. The production of cat filler with a high water absorption and coagulation ability is suitable for you. Such as Zeolite Filler for a cat toilet.

A granulator with a flat matrix produces cylindrical granules for a cat toilet.

Flat die pelletizer Uses clamping videos, which pour materials through the openings of the matrix to form granules. It is more suitable for you for use in the production of small and medium volumes. For some types of wood or biomass cat litter, it can provide better particle shape and size control. For example, Filler for a cat toilet with tofu.

A granulator with a ring matrix production of cat filler.

The granulator with a ring matrix extrudes raw materials into granules through a rotating ring matrix and a motionless clamping video. This machine is especially suitable for working with powdered materials, such as wood chips or paper cat litter. A granulator with a ring matrix can work continuously and has high performance. Suitable for large -scale production. Can help you make a high -quality filler for a cat toilet.

Summing up, You can say, that each type of granulators has its own unique advantages. When it comes to choosing the right granulator for the production of fillers for cats, You need to take into account many aspects. Including comprehensive accounting, raw materials, requirements for production efficiency and quality of the final product. As a professional equipment manufacturer. Providing you equipment, We will also provide you with comprehensive technical support and services. Make sure, that you can produce high -quality fillers for cat toilets, Responsible to market demand.