Creating a plant for the production of organic fertilizers, you will definitely be very concerned about the costs. Below are details about the production of organic fertilizers. Hope, this will help you learn more about the project.

What raw materials can you use to produce organic fertilizers??

The production of organic fertilizers is inseparable from high-quality raw materials. This is mainly livestock and poultry manure., Agricultural waste (such as straw, Rice husk), food industry waste and municipal organic waste. Most organic fertilizer producers typically use livestock and poultry manure.. Such as chicken droppings, Cow navis, свиной навоз и т. e. They have a high nitrogen content, phosphorus and potassium and are ideal raw materials for organic fertilizers. To start a plant for the production of organic fertilizers using these raw materials, you need a stable supply chain. Depending on the source of raw materials, the purchase cost per ton of raw materials can range from 10 to 50 US dollars.

We can provide you with various solutions for organic fertilizer production lines.

Animal manure organic fertilizer production plant

Animal manure is an important raw material for the production of organic fertilizers. It is rich in nutrients and comes from a variety of sources. At creation of this plant The most important production equipment is composting machine. It can help you complete fecal fermentation in a short time. If you do not know, how to choose the right composting equipment. We can recommend you an effective manure composter, based on your project.

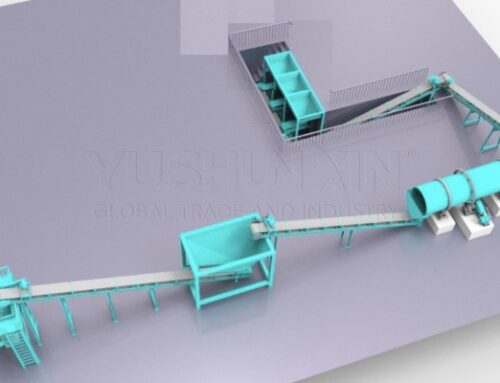

The manure fertilizer production process usually involves fermentation, crushing, granulation And Packaging. Most organic manure fertilizer manufacturers prefer to produce organic fertilizer in powder form. But if you have enough budget, We recommend buying a compost granulator. Organic fertilizers in granular form are easier to transport, store and use.

Lines for the production of organic fertilizers of various capacities.

Organic fertilizer production line design, required for your plant, should be adjusted depending on expected performance. We can provide you with organic fertilizer production line solutions, corresponding to production volume. For example, small Powdered organic fertilizer production line performance 3 T/h and granular organic fertilizer production line medium size 3-8 subject. As well as large-scale organic fertilizer production lines with higher productivity 8 t/h and t. e. We can design the production line solution, which best suits your needs, to ensure the best balance between investment benefits and production efficiency.

Several proposals for creating a plant. Help you better open an organic fertilizer plant?

1. Develop a complete production plan: you need to understand market demand and set clear production goals. Plan production processes and schedules. Including the purchase of raw materials, control of the production process and quality management of finished products.

2. Match the location of your factory with your production facilities capacities: place, which you choose to locate your plant, must be spacious enough and have good transportation conditions. To meet your production capacity needs. This will help reduce transportation costs and improve supply chain efficiency..

3. Determine the type of organic fertilizer plant, which one do you need: based on your production goals and market demand, decide, whether to produce organic fertilizers powdered or granular, or even that, and more. Different forms of organic fertilizers place different demands on equipment and processes.

4. Choose a reliable supplier of fertilizer application equipment. Find a reputable equipment supplier, To guarantee, that the equipment it supplies is of reliable quality and has excellent after-sales service. This will have a direct impact on your production efficiency and product quality..

Shunxin Machinery can provide you with all the necessary production equipment. You can purchase quality equipment at a low price.