What is a drum rotor dryer?

барабанная роторная сушилка - This is industrial drying equipment, которое обычно используется для обработки материалов, containing moisture or other volatile liquid components. In the production of fertilizers Rotor dryer It is key equipment. It is used to reduce moisture content in fertilizers granules, providing good storage stability and liquidity, corresponding to market needs. Excess moisture can cause fertilizer granules to clump or decompose.. You can say, что процесс сушки является важным шагом в обеспечении качества удобрений.

Why drum rotational dryers are widely used in the production of fertilizers?

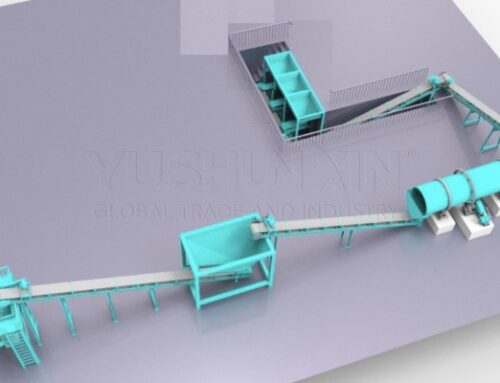

On fertilizer production lines, rotational dryers usually follow the equipment for granulation. The obtained granules of fertilizers before applying to the dryer may contain high humidity, и эту влагу необходимо удалить до соответствующего уровня, to meet subsequent transportation requirements and packaging. Rotary dryers are widely used in fertilizer production due to their following advantages:

The design of a rotary dryer allows the material to have a large area of contact with a stream of hot air. This contributes to the fast heat transfer and effective испарению влаги.

Rotary dryer ensures continuous production process. Contributes to your large-scale production and improved work efficiency.

The drum rotary dryer can use different types of fuel to generate the required heat. Including natural gas, coal, fuel from Biomas and much more, which gives you flexibility in using it.

Некоторые типы ротационных сушилок могут не только сушить материалы, but also contribute to the formation of particles of material in the drying process. This is especially important for the granulation process of fertilizers.

How Our Drum Rotary Dryer Improves Fertilizer Drying Efficiency for You?

Regarding the feeding method, наша ротационная сушилка использует для вас непрерывную и равномерную систему подачи. Через винтовой или The strip conveyor, so that the material enters the dryer at a stable speed.

Выбор печи с горячим воздухом имеет решающее значение для эффективности сушки. We use modern air heaters with automatic temperature control systems. Flame size and hot air temperature can be automatically adjusted in accordance with your drying requirements. Make sure, that you are provided with constant and appropriate heat, необходимое для сушки.

Подъемная пластина является ключевым компонентом внутри сушильной машины. Его конструкция напрямую влияет на подъем, dispersion and heat transfer of materials. Properly designed copying plates allow you to increase the area of contact and contact time with hot air. Наши сушилки позволяют точно контролировать процесс сушки материала за счет регулировки расположения и угла подъемной пластины.

Choosing the right rotary dryer is critical to improving the efficiency and quality of fertilizer production. Fertilizer type, his physical form, scale of production and specific requirements production line – all this will influence the choice of dryer. If you do not know, what to choose, we will be happy to help! We have the most professional knowledge base and engineers, And we will definitely help you choose the most suitable drum rotor dryer for you. Press the button below, To learn more about rotary dryers!