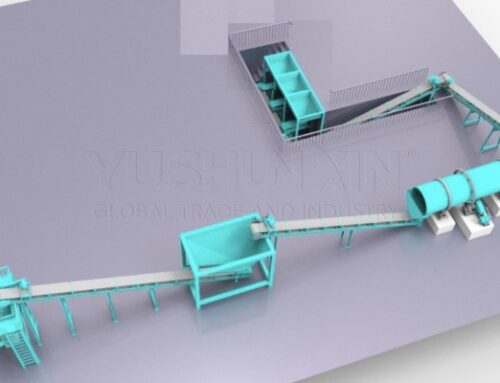

Today in the field of agricultural production, the demand for Phosphorus fertilizers, how on key component of increasing the yield and quality of agricultural crops. For those of you, who is looking for long -term profit, Phosphorus fertilizer production line - This is an opportunity, which cannot be missed. So what equipment and what size the production building is necessary for investment and construction factory for the production of phosphorus fertilizers?

· Crushing equipment.

Phosphate ore is the main source material for the production of phosphorus fertilizers. For the production of phosphorus fertilizers from phosphate ore, it is necessary to chop it. Mill Raymond is widely used equipment for grinding materials, used in the field of mineral processing, building materials and chemical industries. It is very suitable for grinding phosphorite ore and is a grinding equipment, usually used at most plants for the production of phosphorus fertilizers.

· Mixing equipment.

After the completion of the process of acidification, phosphoric acid must be connected to other elements, such as nitrogen and potassium, for preparing complex fertilizer. In this case, you need to use mixing equipment. Double shafts horizontal mixer - This is a high -performance mixing equipment, which can work continuously and completely and evenly mix the materials. Accurate mixing and mixing ensure the uniformity of your phosphorus fertilizer.

· Granulation equipment.

If you need to produce granular phosphorus fertilizers, The granulator will become indispensable for you. There are so many types of granulators, How to choose? We recommend that you choose disk granulator. The central part of the disk granulator is an inclined disc. The surface of the disk is usually covered with corrosion-resistant and wear-resistant materials. Besides, The disk granulator is characterized by low cost and simplicity of maintenance. This is a good choice for equipment for granular fertilizers.

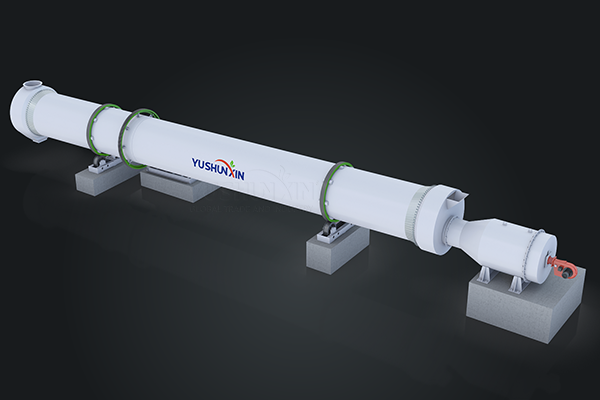

· Drying equipment.

After the powdered phosphorus fertilizer becomes granular, There is still a certain amount of moisture inside. You need to evaporate the water, to ensure compliance with the quality requirements of the final product. Rotary drum drying machine suitable for continuous work and can process large volumes of materials. Moreover, when the drying cylinder works, He rotates, Providing uniform drying materials. Improves resistance to crushing and fertility of phosphorus fertilizers during storage and use.

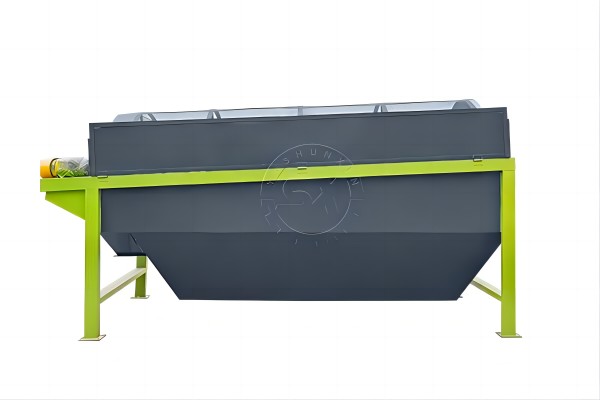

· Sifting and packaging equipment.

The final stages of the production of phosphorus fertilizers usually include sorting and packaging. These steps provide uniformity and product quality, suitable for distribution in the market. You can do this with drum sorting machines and packaging cars. A sifting machine can remove fine powder and oversized particles from the product, Guaranteeing, that the quality and uniformity of the final product meet the requirements. Fully Automatic packaging machine can automatically weigh phosphorus fertilizers and pack them in pre -prepared packaging bags. Save your time and energy.

If you want to invest in the construction factory for the production of phosphorus fertilizers , what size of the production building will be able to satisfy your production needs?

The area of the building of the phosphorus fertilizer plant depends on many factors. Your production capacities, Production process, The technology and size of the equipment used and t. e. Besides, The requirements for the storage of raw materials and finished products should be included, Requirements for an auxiliary room and reserved space for future expansion.

According to our approximate estimates, The production workshop of the middle plant for the production of phosphorus fertilizers usually requires from thousands to tens of thousands of square meters (10 000 – 40 000 square meters or more). For example, If you want to build a plant for the production of phosphorus fertilizers, producing 100 000 ton phosphorus fertilizers per year, it may be required to build the plant with an area of at least 10 000 square meters. However, the specific size of the plant should also take into account the specific requirements of the chosen process and equipment. This number is only a very approximate estimate. If you need more detailed information and assessment of the size of the factory for the production of phosphorus fertilizers, Please, Contact us!