How to make liquid fertilizer from cow manure? Production Liquid fertilizer from cow manure - environmentally friendly and economical method. Liquid fertilizer from cow manure can provide agricultural crops with rich nutrients. At the same time, this can increase the content of organic substances in the soil. Therefore, more and more manufacturers of agricultural products and investors began to pay attention to the project for using cow manure for the manufacture of liquid fertilizer. So, how to make liquid fertilizer from cow manure? Is it worth a project for the production of liquid fertilizer from the cow manure of your investment? In this article we will discuss this issue in detail and hope, that she will help you.

What are the advantages of the line for the production of liquid fertilizer from cow manure, which are worth your investments?

- Low investment costs: The threshold of investment in the line for the production of liquid fertilizer from cow manure is low. The full set of lines for the production of liquid fertilizers costs about 30 000 US dollars.

- Simple production process: The process of production of liquid fertilizer is very simple and does not require complex technology and operator training. This reduces management and operational costs of production and helps to increase profitability.

- Less equipment requirements: The production line requires less equipment. The costs of the purchase and maintenance of equipment are low. Further decrease in fixed costs and operating costs.

- In accordance with market trends: The market demand for organic liquid fertilizers is growing. This trend means, that the production of liquid fertilizers has good market prospects and profit potential.

- FAST NECKING: Due to the simplicity of the process, the product development cycle is short. You can quickly bring products to the market, take the market share and get early advantages.

- High profitability potential: The combination of low investments and high demand makes investments in the line for the production of liquid fertilizers from cow manure potential for high profitability for you.

The project for the production of liquid fertilizers from cow manure has a good development potential. When investing, you need to master mature technology and production processes, as well as choose the right equipment and objects to increase the efficiency of production and product quality. Shunxin liquid fertilizer production line has a mature technology and can help you produce high -quality liquid fertilizers. Welcome to us for consultation.

What are the stages of transformation of cow manure into high -quality liquid fertilizer?

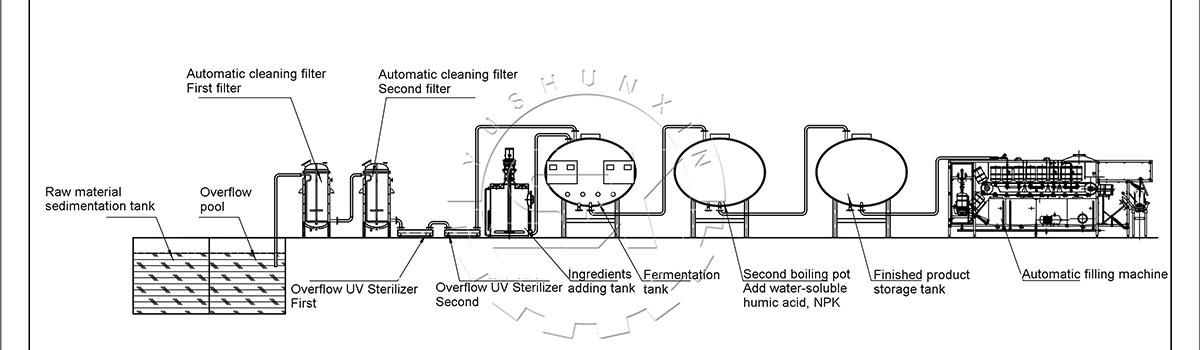

The process of manufacturing liquid fertilizer from cow manure mainly includes four stages: preparation of raw materials, The process of fermentation, Filtering and dilution, as well as storage and use.

Composting. First compost the cow manure. This step reduces the number of pathogens and weeds. In this case, due to the action of microorganisms, the decomposition of organic substances accelerates and the nutritional value of the fertilizer increases.

Fermentation. Mix cow manure and water in Armor reservoir in the ratio of 1:3 to 1:5 (For example, 1 a kilogram of cow manure corresponds to 3-5 liters of water). A specific ratio can be adjusted depending on the dryness and humidity of the cow manure, as well as the content of nutrients in it. You can add some auxiliary materials accordingly, Such as patho, Microbial monoculants and t. e. To accelerate the fermentation process.

Separation. The fermented material is divided into liquid and solid parts using equipment for separation of solid and liquid phases. The liquid part is a liquid fertilizer, rich in nutrients. A hard part can be additionally processed as a soil air conditioner or for other purposes.

Dilution and mixing. Depending on the needs of agricultural crops, the separated liquid fertilizer is diluted and mixed accordingly. To ensure the balance of nutrients.

Storage and packaging. The resulting liquid fertilizer must be stored in a suitable container. You can pack it in products of various specifications to meet market demand.

What equipment and recommendations for choosing you need for the production of liquid fertilizers from cow manure?

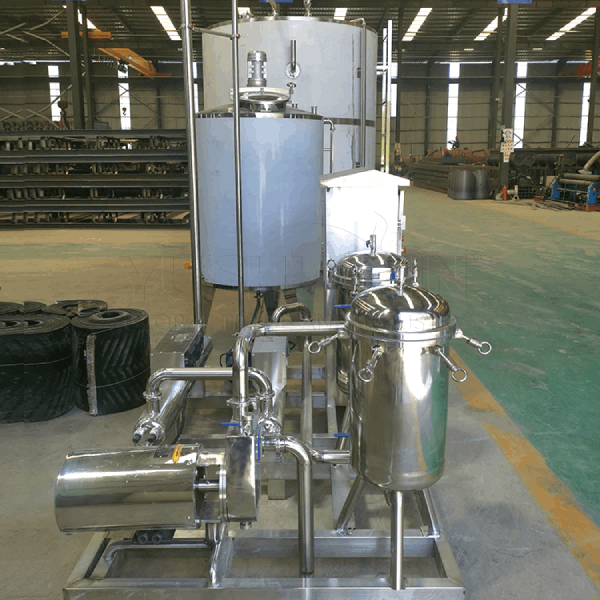

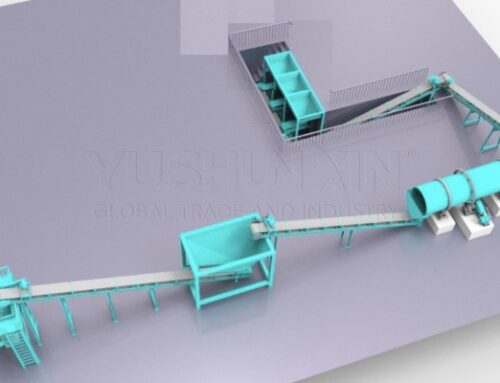

IN liquid fertilizer production process The following equipment is crucial from cow manure:

What are the sizes of tanks for liquid chelative fertilizers we offer for you?

We can provide you with various specifications of tanks for chelating liquid fertilizers. For example, Tanks of volume are common in the market 1 m³, 5 m³, 10 m³, etc.. e. We also accept orders for manufacturing by individual order. If your production needs are great, We recommend that you purchase several tanks for sliding volume 10 m³ for the convenience of transporting and loading containers. If there are special requirements for capacity, The tank can be elongated in accordance with the actual situation. However, Please, Consider the size of the container, to avoid difficulties with transportation and increase in costs. If you have additional requirements, Please, Contact us to discuss individual decisions.

What is the range of prices for the production line for the production of liquid fertilizer from cow manure, which we supply you?

Currently, the range of prices for the line for the production of liquid fertilizers from cow manure in the market is quite wide. Depending on the configuration of production power, degree of automation, Equipment material and t. e. Our liquid fertilizer production lines The following price categories usually have from cow manure:

- Small, Simple production lines (Daily performance 5-20 ton): Prices vary from 15 300 to 50 000 US dollars. Suitable for small and medium ranch and farms.

- Standard production line of medium size (Daily processing performance 20-60 ton): The price is usually 50 000–150 000 US dollars. Suitable for regional agricultural enterprises and large farms.

- Large, Automated production lines (Daily performance 60-200 tons and more): Prices usually vary from 150 000 to 300 000 US dollars and even higher. They are mainly used by large agricultural and livestock enterprises, as well as professional manufacturers of organic fertilizers.

Why do we recommend using composite cow manure to prepare liquid fertilizers?

- Elimination of pathogens. In the process of composting, high temperatures can effectively kill most pathogenic microorganisms. Reduce the potential threat to plants from pathogens.

- Reduces the number of weed seeds: Thermal decomposition during composting also destroys most seeds weeds. Reduces problems with weed growth.

- Stabilizes nutrients: The composting process helps transform the nitrogen of cow manure into a more stable form. Reduce gestation of nitrogen, Due to which nutrients are more easily absorbed by plants.

- Reduces the smell: Composting reduces the strong smell of fresh cow manure. Increasing environmental comfort during use.

- Stimulation of microbial activity: The composting process increases the amount and variety of useful microorganisms. These microorganisms can continue to play an active role in the soil even after, Like them turned into liquid fertilizers.

I hope, that thanks to the above, you had more ideas about that, How make liquid fertilizer from cow manure? If you need appropriate equipment about equipment, Please, Contact us, To get it. We can also adapt to you relevant production decisions. We have rich experience and professional.