How we all know, chicken droppings can be used as raw materials for organic fertilizers. Chicken droppings are rich in organic substances, as well as high, P, K and trace elements. This is a good raw material for the production of organic fertilizers, And many manufacturers prefer it. However, it should be noted, that chicken droppings cannot be used as an organic fertilizer without decomposition. So, What equipment for processing chicken droppings? The usual processing equipment includes composters, Armor vats, crushes and so on. e.

Generally speaking, There are still many equipment for processing chicken droppings, Depending on production demand. Certainly, If there are no conditions, For proper struggle with chicken, you can use such methods, like natural fermentation.

Equipment for processing chicken droppings

The enzyme of the chicken litter.

The reservoir for the fermentation of the chicken droppings is the equipment to protect the environment. Using the decomposition of natural microorganisms, Aerobic fermentation It lasts about 7 days in a closed enzyme. Thus, chicken manure is processed into bioorganic fertilizer, which can be used to grow crops.

Kurin drop -down machine.

The composter for chicken uses modern technologies to process agricultural waste, livestock manure and organic household waste in bioorganic fertilizers for you. Its main function is to turn the material after that, how the raw materials are fermented and heated, so that the fermented material can fully contact the air and increase the oxygen content in the material of the material.

How to ferment chicken droppings to organic fertilizer?

Generally speaking, There are two methods of fermentation of immature chicken litter: One is natural enzyme, and the other is adding The leaven.

Natural fermentation lies in that, to fold chicken litter together, pour a small amount of water, and fermentation takes 2-3 months. For the entire fermentation cycle, you need to turn around approximately 5 once, what takes a lot of time.

If you decide to add fermented crops, You can complete the fermentation through 25 days! For comparison, You spend less time.

When chicken droppings have no unpleasant odor, has white gifs and loose consistency, it means, that the chicken label transferred!

How long does it take to process chicken manure into organic fertilizer using a composter??

Self-propelled composters: 15–22 days to complete the process, Suitable for small and medium -sized industries.

- Mobile tutors of manure require laying the material in the rolls. This is semi -automatic, and the operator controls the composter, moving it along the trajectory. Regular turning of the heap (1-2 once a day) allows you to replenish oxygen reserves and adjust the temperature.

- The fermentation cycle significantly depends on the environment. If the ambient temperature is suitable (For example, In spring and autumn), and preliminary processing meets the standards (The content of water and the ratio of carbon and nitrogen meet the requirements. From chicken to full composting, it takes 15-18 days. At low temperatures in winter or rainy summer, additional shelter is required to maintain heat/protection from rain. The duration of the cycle will increase to 20–22 days.

- This equipment has a low cost and is suitable for small and medium -sized production lines (processing 2-5 tons of chicken litter per day). Despite, that the cycle is longer, than the enzyme, It provides high economic efficiency. It can satisfy the needs of the production of basic organic fertilizers.

Enzymatic vat: The transformation of manure into fertilizer ends behind 7–10 days, is characterized by high efficiency and intelligence.

- Armor vat It is a closed intellectual equipment. Environment of enzymation (Temperature 55-65 ° C., humidity 50%-55%, Forced oxygen supply) It is precisely controlled by the system. Not affected by external climate, Microbial activity is stable.

- Pre -processed chicken droppings (Humidity 50-60 %, carbon to nitrogen ratio 25:1–30:1) added to tank without frequent manual intervention. The equipment automatically supports the high -temperature composting period within 5-7 days (Destroying pathogens and decomposing organic substances). From raw material supply to complete fermentation (when the material meets the "raw fertilizer" standard) It only takes 7–10 days.

- This equipment is suitable for medium and large production lines. This not only reduces the cycle, but also ensures the uniformity of nutrients in the finished fertilizer. It can be directly used for deep processing in order to obtain high -quality organic fertilizer.

It is better to use dry chicken droppings or wet chicken droppings?

For comparison, The use of dry chicken droppings is usually preferable to wet chicken droppings for the following reasons:

- Dried chicken droppings and easily distributed, And the distribution effect is more uniform, which is favorable for the survival and development of agricultural crops.

- When using wet chicken, it is inconvenient to work, And due to uneven introduction, it is easy to cause root rot of crops.

- Wet chicken droppings more microbes, which can become carriers of poultry diseases.

- The use of wet chicken in vegetable greenhouses will lead to a burn of seedlings and rotting the roots of vegetables.

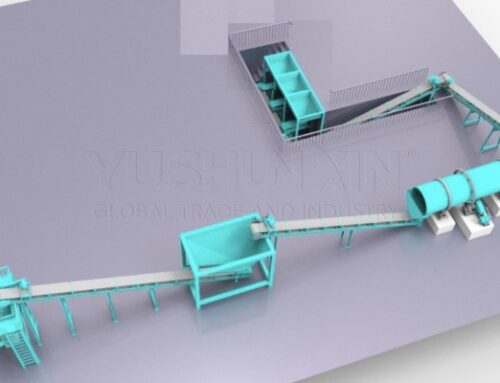

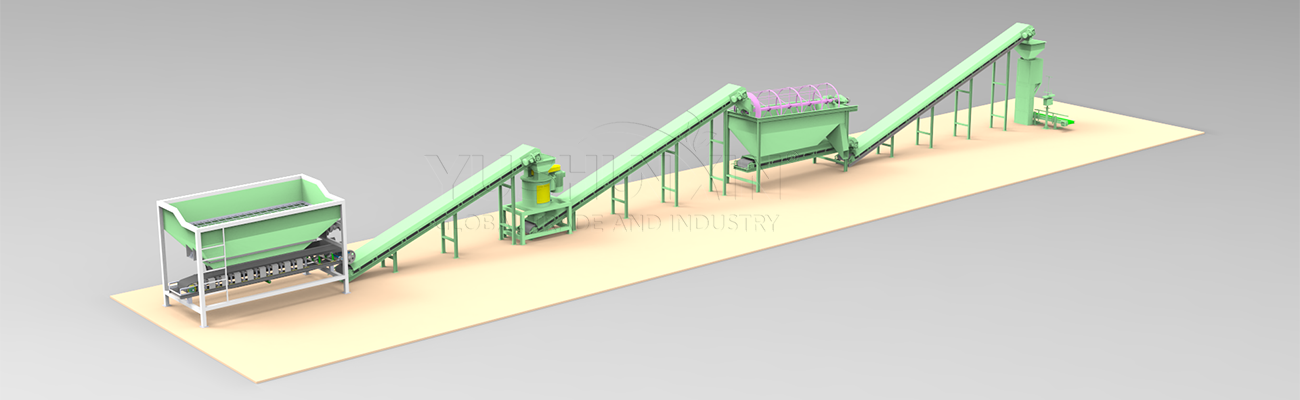

Line for the production of organic fertilizers in the form of powder chicken droppings